Find robot palletizing flexibility for all your SKUs

What are you Palletizing?

No matter what type of product needs palletizing, MCRI has successfully stacked it. And we can help you start stacking.

From a simple, one robot cell to more complex multi- robot palletizing systems, we develop your robotic palletizing system to be the optimal solution for your process.

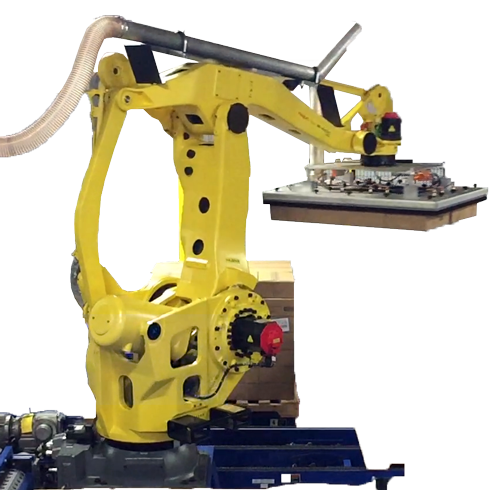

Case Palletizing

We palletize an almost endless multitude of different sizes, shapes, and weights of cases.

Can you stack

- Corrugated cases

- Split-top cases

- Plastic cases/cartons

- Metal cases/cartons?

We can!

As the leading experts in case palletizing, we design highly flexible, customized solutions using cutting-edge robotic and vision technologies.

Need us to pick

- One box

- Two boxes

- Three boxes

- Full row

- Full Layer

- Depalletize

- Multiple case orientations

- Or do something custom

You got it!

Interested in implementing or just discussing a robotic case palletizer for your facility?

Can/Pail/Barrel/Drum Palletizing

Palletizing cylinders for a variety of industries like paint & chemical, medical, building & construction, and others calls for specific, yet flexible design options. MCRI can design a system that will handle different products by designing custom end of arm tooling, so changeover between drum sizes or load patterns can be easily accomplished by either the operator or through the design of this tooling.

Many times filled drums or pails can be heavy and having a robot do the heavy lifting will lower on-the-job injuries related to manual palletizing. The robot’s smooth and consistent movements will also help to improve quality and production rates.

Interested in implementing or just discussing a robotic can palletizer for your facility?

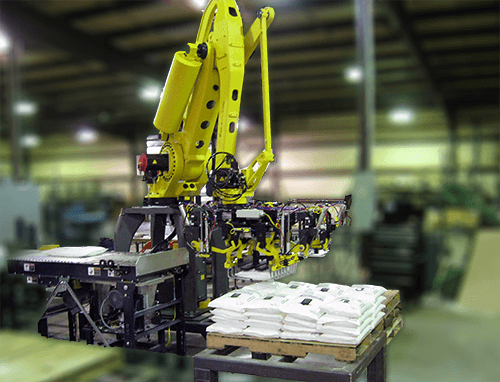

Bag Palletizing

Implementing a robotic bag palletizing system will benefit your process:

- Palletize a variety of bag sizes in one location.

- Increase your employee safety and ergonomic issues.

- Consistent handling with a custom designed end of arm tool means less product damage and dropping.

- Flexible, fast systems increase rates and overall production (High cycle rates up to 28 robot cycles per minute for bag handling).

- Easy to operate systems for variable pattern placement programming and mixed load pallets.

- Systems can reduce floor space requirements

Interested in implementing or just discussing a robotic bag palletizer for your facility?

![]()

Plastic Palletizing

Robot systems for plastic palletizing must be not only flexible but allow for quick changeover. MCRI knows the plastics & container industry is dynamic with line changeovers every time product orders are filled (can be dozens a day) and demand varies to meet end consumer needs for varying sizes in product selection.

Robotics adds a high amount of reliability, flexibility, and even mobility to these applications by:

- Eliminating the manual process of picking and packing plastic bottles

- Improving worker safety by decreasing repetitive motion injuries.

- Reducing cost by simplifying the process and changeovers.

- Allowing for the ability to better plan for product accumulation.

- Increasing quality with more consistent controls of packing bottles.

- Making it easy for the operator to program new products.

- Automating other process such as descrambling/picking, transporting, case packing, and removing bottles from blow molding machines

Motion Controls Robotics understands the process requirements from working with various companies in the industry.

Interested in implementing or just discussing a robotic plastic palletizer for your facility?

Warehouse Palletizing – Depalletizing

MCRI has designed a variety of complex, multi-robot systems to sort and palletize/depalletize product in high-rate, top speed environments.

Improvements and innovations in robotic automation solutions such as an increasing number of robot model variations, 2D & 3D vision for robot guidance and product inspection, and para-metrically driven control software have given rise to flexible, cost effective, high return on investment automation in the distribution work space.

- easier to scale capacity up and down for high and low demand times

- increase process reliability and decrease required floor space

- speed up operations, maximize order fulfillment efficiency

- improved accuracy in product selection for fewer customer returns and refunds due to picking errors

- centralized data entry and integration with ERP system

- less damage in packaging – better quality retail-ready pallets

- improved bottom line of your distribution facility

Interested in implementing or just discussing a robotic warehouse palletizing for your facility?

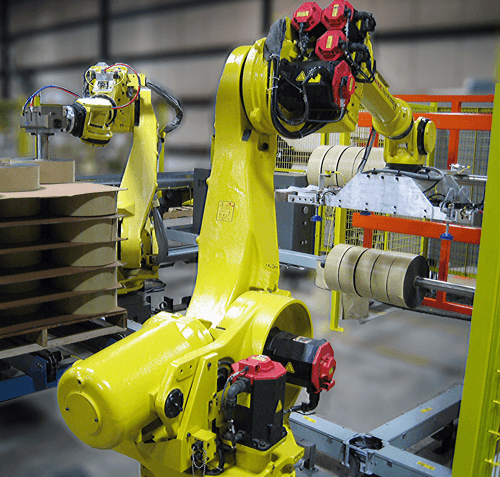

Roll Palletizing

Rolls come in all sizes and weights and are typically a softer product that needs more careful handling than some of the other products we palletize. Rolls can be removed from winding/slitting operations or upstream packaging operations and palletized with the eye in a vertical or horizontal orientation. The system can be designed with an out-feed conveyor for sorting, quality, or product tracking.

MCRI builds custom end of arm tooling to push the slit rolls from the slitting mandrel, pick the roll by its inner diameter (ID), and then palletize the product in a variety of patterns to meet order requirements.

Shrink wrappers can be added to secure the rolls when pallets are moved out of the cell.

Interested in implementing or just discussing a robotic roll palletizer for your facility?

Easy-to-use robot palletizing systems:

- increase your throughput while reducing operating costs and floor space.

- decrease employee ergonomic & harsh environment injuries.

- increase quality with improved product tracking.

- bring flexibility to your process by adding easy changeover options.

- are low maintenance systems with high reliability & superior up-time.

Feeling apprehensive about starting? – We team with our customers to be the robotic expert and prove out the system.

Our years of integrating robots has proven the importance of the integrator being there to collaborate and answer questions.

- We start with robotic 3D simulations for concept verification

- Continue by providing a constant communication network through your project manager

- Run Factory Acceptance Testing before shipping

- Provide on-site training with first run

- And we leave you with 24/7 support after install

What should you expect from any robotic palletizing system?

- Reliable Robotics – Systems are built around highly reliable FANUC robots with payload capabilities up to 2300kg (includes EOAT weight).

- A vertically integrated facility to supply peripheral equipment and keep your project on schedule.

- Recipes for storing part data such as product size, packing pattern, place locations and vacuum pattern.

- Product data tracking through barcode readers.

- Easy to navigate Human Machine Interface (HMIs) for recipe adjustments, pattern teaching, and error reporting.

- Robotic vision systems for product inspection, part location, line tracking, and more.

- Custom built slip sheet racks, pallet racks, or automated pallet dispensers.

- Sensors to regulate process: safety sensors, pallet present, product present, stack height, and other needs.

- Custom multifunction end effectors that can handle pallets, bottom sheets, top sheets, trays, and/or top frames with no need for a tool change.

- Finished pallet takeaway with pallet conveyor, SmartCart AGCs, transfer carts, and/or AMRs.

- Upstream processing to prepare or sort product for palletizing, full pallet transfer and accumulation conveyors.

- Variable pattern placement programming handles various stack patterns.

- Every system meets or exceeds RIA and ANSI safety requirements.