Robotic CNC Machine Tending

Motion Controls Robotics can help you develop a system to automate your CNC machines, improving your competitiveness. Motion Controls Robotics has developed and installed CNC machine tending systems that feed robots by a conveyor or chest of drawers. These drawers can be loaded up and stocked on Friday, so you can come back to work Monday with completed parts in the same chest of drawers. This allows your talented team to set up runs for CNC machines versus loading and unloading machines.

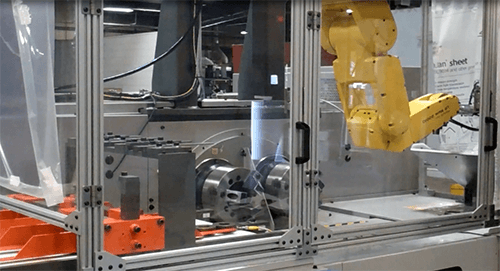

Motion Controls Robotics specializes in loading and unloading Kitako CNC machine tools with FANUC robots. The Kitako HS4200N is a unique machine with two sets of dual machining chucks – 4 total – giving the machine excellent throughput capabilities. Manually loading and unloading this machine at maximum throughput with zero errors to obtain maximum yield can be challenging for an operator.