Recently, we received a call from a customer with a vacuum problem on an end of arm tool. We included “pre-set” vacuum switches on the end of arm tool for part present detection. One of the switches stopped working (failed to detect adequate vacuum) and they called us to help them do some troubleshooting.

Recently, we received a call from a customer with a vacuum problem on an end of arm tool. We included “pre-set” vacuum switches on the end of arm tool for part present detection. One of the switches stopped working (failed to detect adequate vacuum) and they called us to help them do some troubleshooting.

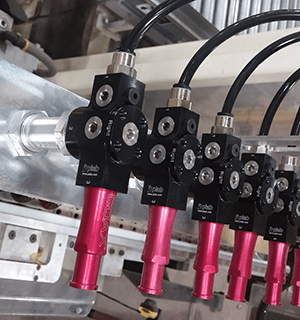

It turned out the Piab COAX type vacuum pumps we supplied with the tooling were not generating enough vacuum (even though the tool would still pick the parts) because of an accumulation of metal shavings in the pump cartridge. These vacuum pumps are very simple and normally very reliable.

It turned out the Piab COAX type vacuum pumps we supplied with the tooling were not generating enough vacuum (even though the tool would still pick the parts) because of an accumulation of metal shavings in the pump cartridge. These vacuum pumps are very simple and normally very reliable.

This article will explain how to prevent or solve this type of problem if it is occurring in your system.

To the left is a picture of one of the cartridges from the Piab vacuum pumps from the customer. You can see the aluminum shavings that got into the Venturi cartridge. The bigger issue that caused the vacuum failure was the debris accumulation on the inside of the vacuum generator cartridge (not shown).

Cleaning the COAX Cartridge

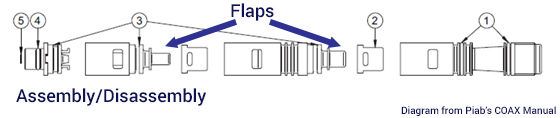

Cleaning the cartridge involves first disassembling the cartridge as shown below and then removing all debris. The COAX cartridge manual recommends cleaning the cartridge by blowing off debris with an air compressor or cleaning in water and letting dry completely.

Reassembly of Cartridge

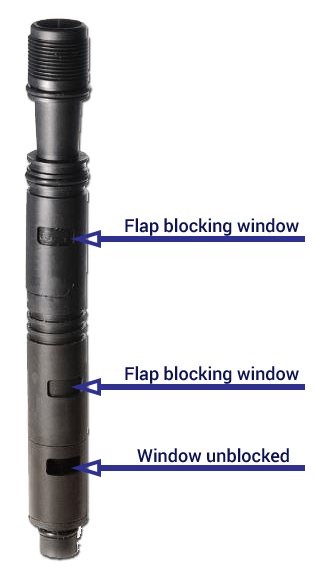

After cleaning the cartridge, it is important that all of the pieces of the COAX Cartridge are assembled properly. If they are not, you will still get a vacuum but it will be reduced by some percentage. Inside each piece is a key that the rubber flaps need to go around. If installed properly the rubber flaps will be blocking the windows as shown.

Replace the cartridge back into the vacuum pump assembly and continue to clean the remaining cartridges using the same technique.

If you have any questions or comments about this preventative maintenance/problem solving article, please contact our support line by phone at (419) 334-5886, Press ‘2’ or email.