Demand for production, packaging and warehousing requirements for rolls and other cylindrical objects can be found in a wide variety of industries. And Motion Controls Robotics (MCRI) is leading the way to apply robotics in areas where rolls and other cylindrical items are robotically manufactured, processed and warehoused.

Demand for production, packaging and warehousing requirements for rolls and other cylindrical objects can be found in a wide variety of industries. And Motion Controls Robotics (MCRI) is leading the way to apply robotics in areas where rolls and other cylindrical items are robotically manufactured, processed and warehoused.

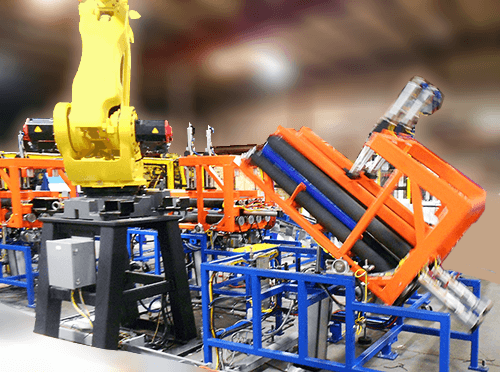

In one MCRI packaging/palletizing cell, rolled roofing product travels on a conveyor from continuous production line to palletizing area. Rolls are fed into a combination roll shaper/up-ender that reshapes the product and prepares it for robotic pickup. The spinning operation takes material that has sagged during transit from the roll production machine to the packaging/palletizing area and makes it concentric again. The shaper is then tilted 90 degrees to stand up the rolls, and the robot uses a pair of inflatable mandrel on its end of arm tooling to pick up the pair of waiting rolls.

A simple vision process at the up-ender allows for the robot to orient rolls the same way on the pallet for point of sale display.

In another Motion Controls Robotics robotic roll handling cell, slit rolls are stripped from mandrels, sorted and palletized. A wide variety of other repetitive packaging operations such as inspection and stretch wrapping can be performed as well.

In the robot cell shown in the adjacent photograph, two FANUC R2000 robots work together to remove slit rolls from a winder/slitter operation and palletize them. Full and partial pallets can be formed within the robot cell. One robot moves a pallet from the empty pallet delivery conveyor and places it on the palletizing conveyor. The same robot places an empty tier sheet on the waiting empty pallet and then moves to the slit roll mandrel staging area. This robot slides the waiting slit rolls one at a time onto the end of arm tool (inflatable ID gripper style tool) of the second R2000 robot. The second R2000 robot rotates the roll from eye-horizontal to eye-vertical, and places it on the pallet at the palletizing position. Product can be stretch or heat shrink wrapped prior to being placed on the pallet at the palletizing position.

In the robot cell shown in the adjacent photograph, two FANUC R2000 robots work together to remove slit rolls from a winder/slitter operation and palletize them. Full and partial pallets can be formed within the robot cell. One robot moves a pallet from the empty pallet delivery conveyor and places it on the palletizing conveyor. The same robot places an empty tier sheet on the waiting empty pallet and then moves to the slit roll mandrel staging area. This robot slides the waiting slit rolls one at a time onto the end of arm tool (inflatable ID gripper style tool) of the second R2000 robot. The second R2000 robot rotates the roll from eye-horizontal to eye-vertical, and places it on the pallet at the palletizing position. Product can be stretch or heat shrink wrapped prior to being placed on the pallet at the palletizing position.

This team work between the two robots continues until the slit rolls are palletized, at which point the slit roll mandrel is moved by the robot to a replenishment position at the roll winding/slitting machine, and the process is repeated until the pallet order is completed. This order filling process is repeated until all pallets are completed for a specific roll winding/slitting setup.

In the “roll handling” application, shown in the adjacent photo, empty cylindrical cans each with carrying handle need to be oriented, then palletized. The handle on the empty can needs to be oriented properly so it can be densely palletized. MCRI designed an automation station with vision process that spins the empty can to the correct orientation. MCRI engineers have many other such tools in our design drawer for use in your robotic work cell.

Contact a Sales representative from Motion Controls Robotics Inc at 419.334.5886 for assistance with your roll handling project.