FANUC’s M-2000iA series 6 axis robot is the heavy weight champion when it comes to payload and reach. The reach of the robot helps to save money on conveyors and other devices to lift heavy product. Due to the size of the M-2000iA robot, it can only be installed on the floor. The series offers two models:

M-2000iA/900L – (long arm) has a payload of 900kg and a reach of 4.7 meters and vertical stroke of 6.2 meters.

M-2000iA/1200 – (short arm) can lift 1200kg (1350 kg payload option available) with a reach of 3.73 meters which previously would have required two robots to accomplish.

The M-2000iA robots are perfect solutions for:

• Large material handling

• Large fabrication handling

• Machine tool load/unload

• Glass handling

• Roll handling

• Casting operations

• Automotive operations

• Large sheet or panel handling

The M-2000iA series wrist has an ingress protection (IP) rating of 67 meaning it is protected in hazardous environments against dust and immersion of liquids between 15 cm and 1 meter. The M-2000 is operated using the R-30iB controller that includes iRVision for guiding, tracking, error proofing, and quality controls as well as force sensing.

The Dual Check Safety (DCS) that come with the M-2000iA robot moves some safety function within making sure that the robot only travels in its defined path. This software adheres to the safety guidelines set forth by the Robotics Industry Association (RIA). DCS can also help to reduce the floor space required by eliminating certain robot movements.

Automation System Examples:

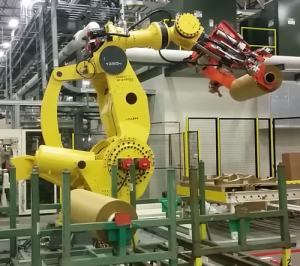

One of Motion Controls Robotics’ specialties is designing and implementing roll handling systems. We have used the M-2000iA in multiple systems to help customers move very heavy rolls from one location to another for converting or other applications. We have also used the M-2000iA to remove bottlenecks through providing constant roll winder tending. These projects were accomplished with the help of a MCRI custom designed and manufactured end of arm tool.

M-2000iA Roll Handling Video

Here jumbo rolls of specialty product are first slit and then wound onto a mandrel. The FANUC M2000iA robot picks up the mandrel using the custom designed end of arm tool.

M-2000iA Image of Roll Handling System

In this application the short arm M2000iA is used to move rolls to multiple stations in a process. The robot is also used for roll winder tending to keep the system running at a constant speed.

Download the M-2000iA Tech Sheet to learn more and if you have any questions contact Motion Controls Robotics through our online request form.