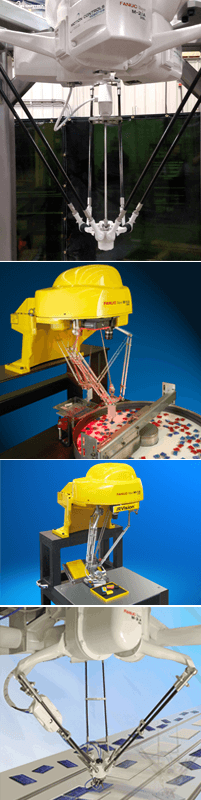

There are four types of industrial robots: Articulated, Cartesian, Delta, and SCARA. While Motion Controls Robotics doesn’t work with cartesian robots, we do integrate the others into a variety of different end of line or fulfillment solutions. Delta robots have their niche in the industrial realm because some jobs require a very high speed, light payload robot. In these cases, we select to integrate one of FANUC’s Delta robots. Delta robots are also known around the industry as parallel or spider robots.

There are four types of industrial robots: Articulated, Cartesian, Delta, and SCARA. While Motion Controls Robotics doesn’t work with cartesian robots, we do integrate the others into a variety of different end of line or fulfillment solutions. Delta robots have their niche in the industrial realm because some jobs require a very high speed, light payload robot. In these cases, we select to integrate one of FANUC’s Delta robots. Delta robots are also known around the industry as parallel or spider robots.

Delta robots are mainly used in applications where the robot is picking products in groups and placing them in a container or in an assembly pattern. Added vision technologies allow Deltas to distinguish and select different size, color, or shape options and pick and place based on a programmed pattern.

Employee Health and Safety

Delta robots are designed to move at high speeds and perform repetitive tasks quickly and consistently. These robots can replace manual processes where over a 100 parts per minute are being picked, sorted and placed. Delta robots are being used to not only improve consistency and quality of processes where repetitive movements ultimately lead to employee mental fatigue, but they also remove the issue of repetitive motion injuries.

Repetitive motion injuries are caused by bending, reaching overhead, working in awkward postures or just performing the same or similar tasks repetitively. Musculoskeletal disorders account for 33% of work place injury and laborers are the 2nd mostly likely candidates for these injuries according to OSHA. These are some repetitive motion injuries that can be removed using Delta robots:

- Carpal tunnel syndrome

- Tendinitis

- Rotator cuff injuries (a shoulder problem)

- Epicondylitis (an elbow problem)

- Trigger finger

- Muscle strains and low back injuries

FANUC Delta Robot Models

M1iA – FANUC Delta Robots

Axes Available |

Payload |

Reach / Work Envelope |

||

| 3, 4 or 6 axes | 1kg (2lbs) | 280mm / 280 x 100mm |

The perfect model for very light payload picking and/or assembly of small parts. Because of its delicate functionality, this robot is as dexterous, but more consistent, than a human hand. The M1iA is often used in industries such as food, pharmaceuticals, and electronics.

The M1iA can utilize iRVision for line tracking to pick items off a conveyor and force sensing for assembly or placement purposes. The small footprint and designated work envelope of this robot makes it easy to place near manual operations.

M2iA – FANUC Delta Robots

Axes Available |

Payload |

Reach / Work Envelope |

||

| 3, 4 or 6 axes | 3kg (6lbs) or 6kg (13lbs) | 1130mm /1130 x 400mm |

The M2iA can handle items up to 13 lbs. with flexibility and speed comparable to the very light payload M1iA. The M2iA comes in 6 different models to meet combined space and speed requirements for picking, sorting, and assembly.

This robot is also designed to utilize iRVison and Force Sensing for applications when picking items off a conveyor and placing them in a designated order or as a part of an assembly process. Remote Force Sensing allows the robot to perform more difficult assembly applications quickly.

The M2iA has IP69K dust and high pressure liquid protection as standard, so it is built for working in food environments using food grade oils and/or dirty environments where the robot needs frequent cleaning.

M3iA – FANUC Delta Robots

Axes Available |

Payload |

Reach / Work Envelope |

||

| 3, 4 or 6 axes | 6kg (13lbs) or 12kg (26lbs) | 1350mm / 1350m x 500mm |

The FANUC M3iA continues the growth in payload capability keeping consistent performance at high speeds. This model’s increased payload makes it possible for automotive facilities to take advantage of the precise, high speed assembly capabilities as well as the other industries mentioned above.

This increased payload also allows for a more complicated multi-gripper design for flexibility in operations. The M3’s larger work envelope makes it an improved replacement for SCARA robots.

The same smart technologies are available in the M3iA, iRVision and Force Sensing. Each model is perfectly designed to meet needs such as high speed picking and assembly. The M3iA is also uniquely able to part feed from the side of a work zone which increases its available workspace. Lastly, the M3 model is available with IP67 protection making it suitable for use in food environments.

If your facility has a high speed sorting or assembly process where consistency and quality are of high importance, contact MCRI to learn more about the healthy alternative of using delta robots.