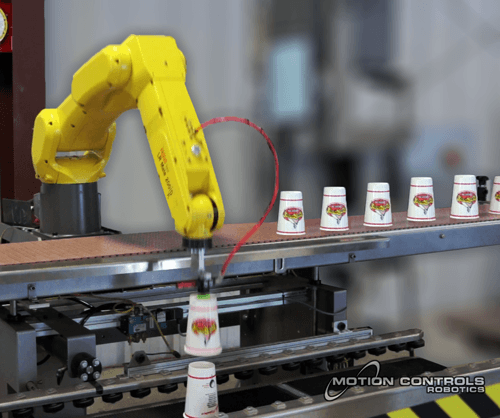

Basic Line Tracking is used in robotic pick and place applications where products are being picked off of a moving conveyor, placed on a moving conveyor, or both. Line Tracking uses an encoder mounted directly to the drive shaft of the conveyor or to an encoder wheel placed directly onto the conveyor’s traveling surface. When using basic Line Tracking, a sensor is triggered and the robot starts tracking for the picking or placing process. In this application, the products have to be presented in the same order to the robot because there is no vision to correct for randomness in pick location.

Machine vision is used in a growing number of robot cells – sometimes for a variety of reasons. Vision can help to locate, track, and inspect products. 2D or 3D vision can be used in the robot application. Motion Controls Robotics uses FANUC’s iRVision and Cognex camera solutions to solve customers’ challenges with vision.

One example of a vision application used to solve more complicated robotic pick and place problems is Visual Line Tracking. The first step to Visual Line Tracking is setting up the basic Line Tracking described above. Then the machine vision camera is calibrated to the Line Tracking setup so they work together. The camera snaps the image, finds its orientation across the conveyor, and records the encoder information. So when the product moves into the robot’s work area it can be tracked along with the vision offset.

How does Visual Line Tracking work?

- The camera, installed upstream from the robot, takes an image.

- Based on the conveyor rate, the system is setup to have trigger intervals that control how often the camera takes an image to locate the products on the conveyor.

- The software makes a grid of the conveyor locating the products.

- Each product location is transferred as a set of coordinates to the robot.

- As the product moves into the reach of the robot, the robot selects the product based on the grid location and conveyor speed.

- Product is then placed in a case, on another conveyor, or as part of an assembly process.

Visual Line Tracking has a wide range of product applications from picking smaller objects from quickly moving conveyor (conveyor speeds can exceed 250 ft/minute) using high speed delta robots to picking heavier payload objects like car frames with larger, higher capacity, slower moving robots off of continuously moving assembly lines.

FANUC’s iRPickPRO is the setup software used to input product data, design, and simulate the robotic pick and place process. Both Line Tracking and Visual Line Tracking have the same core software option. The software includes options to optimize the picking process through different types and speeds of conveyors and single or multiple picks. FANUC’s iRPickTool Software is needed when setting up multiple robot line tracking applications. This software helps to simulate and setup for best load balancing using multiple robots.

Video for Robotic Pick and Place using Line Tracking

One of the latest software options for both Line Tracking and Visual Line Tracking setups is the Ethernet Encoder option. In the past, a Multiplexer Board was used to bring in a single Encoder and then distribute the encoders signal to multiple robots using multiple cables. In this scenario, each robot required a Line Tracking Board. With the Ethernet Encoder option, an Ethernet network serves as the connection between multiple robots and only the “Master Robot” requires Line Tracking Hardware.

If you would like to learn more about line tracking download the FANUC tech sheet. Contact Motion Controls Robotics to learn more about integrating a robotic pick and place line tracking or visual line tracking application.

If you would like to learn more about line tracking download the FANUC tech sheet. Contact Motion Controls Robotics to learn more about integrating a robotic pick and place line tracking or visual line tracking application.