First time purchasers of robotic work cells have interesting insights and questions about their new robotic work cells.

Don’t like long articles? Jump to the Summary >>>

Don’t like long articles? Jump to the Summary >>>

Since 1996, when Motion Controls Robotics began selling and installing robotic work cells, there have been several questions that come up repeatedly from customers who are new to robotic system integration and integrators. If you are new to robotic palletizing and other robotic work cells for manufacturing and warehousing, we hope you can use these questions to gain some confidence to move forward on that project you have been considering. We want you to be ready for the wave of robotic automation coming to manufacturing and warehousing.

Robotic Palletizing Cells – Question 1

Why is the palletizing cell safety system laid out the way it is?

Safety is every robot manufacturer and integrator’s first priority, and generally is a first priority of your company as well. Robotic work cell safety is governed by the A3 Association for Advancing Automation and the American National Standards Institute, or ANSI.

The latest governing document is ANSI/RIA R15.06-2012 safety standard.

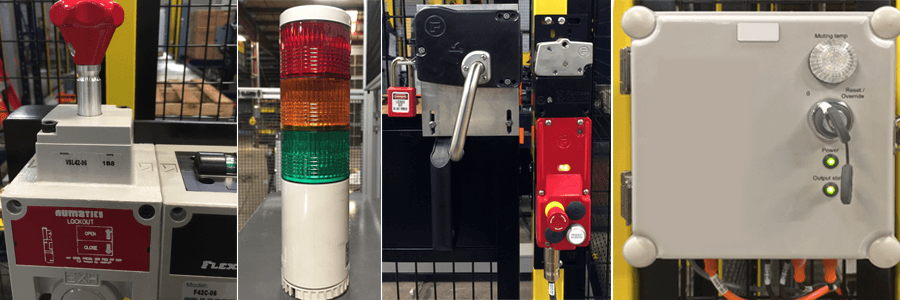

Some of the basic concepts of the standard include; lockout/tag-out guidelines and requirements, minimum clear distance from operating equipment, dual check safety and acceptable safety barrier types. The standard is designed to protect programmers, operators, and maintenance personnel from the hazards of automatic equipment operation.

While much of the standard is clear cut, there is still room for interpretation and one company does not always “solve” a safety challenge the same way another company would. As a customer of a new robotic palletizing cell, it is smart to ask your supplier/integrator for a copy of the Risk Assessment Review that was done for your cell. This may give you some insight as to why light curtains are set at a certain distance from load positions or along conveyors, why fences are located where they are, why a safety rated air cutoff device was provided, why the robot end of arm tool goes to a particular state or condition when an emergency stop occurs, why emergency stop pushbuttons and cords are located where they are and operate the way they do.

Also, know that safety standards are periodically updated as new safety technology becomes available and as different safety related circumstances occur in industry. An example is the introduction of AMRs and Cobots. These led to major updates to the safety standards. The goal is to provide the latest, best safety guidelines for every new robot cell installed. It is wise to periodically review the design of your safety equipment to determine whether or not there are logical new safety standards and equipment to incorporate into your cell. This can also be done by your system integrator as part of your ongoing Preventive Maintenance program.

Robotic Palletizing Cells – Question 2

How long will the robot in our new robotic palletizing cell last?

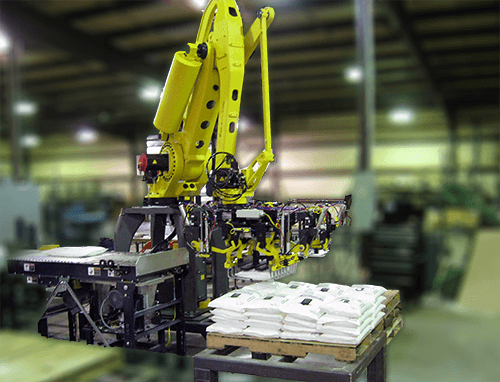

The simple answer to this question, at least for robots manufactured by FANUC, the leading supplier of robots throughout the world, is that the newest robots are running from 80,000 to 1000,000 hours mean time between failures. A typical work shift in North America is about 2,000 hours, so you can expect a new robot to run anywhere from 10 to nearly 20 years in a three shift operation.

But, you may protest, nothing runs that long. How can a new robotic palletizing cell run that long?

- Just as advanced computer design tools and sheer experience have allowed automobile manufacturers to lengthen service intervals on automobiles, and automobile reliability has improved after many years of refinements, robot manufacturers have used these tools to develop and refine motor designs, servo motor controls, and mechanical assemblies of robots.

- Robot motions have been optimized to reduce instantaneous loads on motors and reducers. Robot arms/castings have been optimized to reduce mass and increase strength.

As long as a robot is used within its design parameters and basic preventive maintenance is performed, there is little to fail on a robot and there is a very good chance your robot will run for 10 to 20 years without a failure.

Three important parameters determine the life of a robot in a palletizing, case packing or material handling application:

- Product Weight – You wouldn’t bring a 12 ton pickup to a gravel pit to pick up 4000 pounds of gravel (though some have tried). Likewise, you do not want to undersize a robot for an application. Palletizing 80 pound bags of concrete will require a different robot/robot speed solution than palletizing 20 pound cases of plastic cup lids (we have palletized both – for different companies of course).

- Product Inertia – This is a frequently overlooked element of robot applications – long, wide, or deep loads place larger moment loads on a robot arm than small, compact loads. Moving large loads that are well within the weight capacity of a robot but outside its inertia limits can result in oscillation in the robot’s motors that at best will reduce the robot’s life cycle, and at worst can result in out of control motion of the robot. Make sure your robot integrator takes into account the inertia of both the end of arm tool and product(s) when sizing your robot and selecting its operating speed.

- Duty Cycle-Throughput is a key determinant of robot cell uptime and reliability. FANUC now uses case and bag palletizing rates of 20 + moves per minute, or less than three seconds per move. Tall pallet loads require longer moves than shorter pallet loads on average, so pallet height will in part drive robot cycle time as well. In addition, if you need to run a robot flat out for its entire life, you will end up with far more wear and tear than if you have intermittent peak demand on the robot.

In conclusion, there are some simple things that can be done to reduce the robot’s duty cycle in a typical palletizing, case packing or general material handling application; some that the robot integrator can do for you, others you can do for yourself.

- Optimize location of the input and exit conveyors to reduce robot arm travel distance between pick and drop locations. A few inches may not seem like a lot, but a robot running 4 second cycles at 90% utilization, 24 x 6 days per week will run 6,065,280 cycles – in one year. And 60 million+ cycles in ten years. A few inches per move in each direction (between pick and drop) will amount to about 1.5 million feet of robot motion (without getting too specific about axis motions, etc.) over a ten year period – a lot of motion for a set of gears and electric motors and drives!

- Use smart programming to limit robot motion and make it as smooth as reasonably possible.

- PM your robot(s) regularly – fresh grease every 3 to 6 months depending on duty cycle, per the robot manufacturer’s specifications, can significantly reduce robot wear and tear and increase the robot’s life. And do not put cheap substitute grease in your palletizing robot.

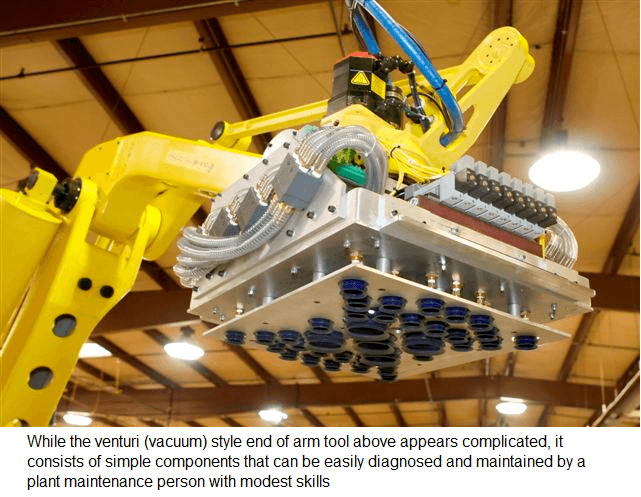

Other elements of the robotic palletizing cell that will impact its overall uptime and reliability include end of arm tool design and supporting conveyor and material handling equipment such as pallet dispensers.

Other elements of the robotic palletizing cell that will impact its overall uptime and reliability include end of arm tool design and supporting conveyor and material handling equipment such as pallet dispensers.

- The end of arm tool will likely require service of some type within a seven to ten year window.

- Incoming case or bag conveyor can run for many years of operation with minimal service if you size it properly for the application, purchase it from a reputable company like Motion Controls Robotic’s conveyor partner, Omni Metal Craft ,keep photocells clean and limit switches adjusted, and perform routine maintenance like greasing and chain tensioning.

- The same goes for full pallet exit conveyor and empty pallet rack or dispenser. Make sure to do regular maintenance for a long lasting cell.

Robotic Palletizing Cells – Question 3

What happens if the robotic palletizing cell fails after you have left our site?

Owners of a new robot cell should have two primary concerns about maintenance and ongoing support of their cell(s); equipment failure and the need to make changes to the robot’s program or operation. Each of these areas of support is discussed below.

Common robot cell components include:

- Safety equipment (light curtains, push buttons, pull cords, safety relays, air dump valves)

- End of arm tooling (could be air or electric/servo controlled)

- Conveyor or means to deliver raw product or parts to cell, if applicable

- Conveyor or means to take away finished product or parts from cell, if applicable

- Part registration mechanism(s)

- PLC to control equipment within cell and/or interface with equipment outside of cell

- Input/output modules and conveyor drives to send/receive signals to/from sensors and drive motors

- Vision equipment, if applicable

- Robot and its controller

If you show the above list to the typical plant maintenance person, they are likely to be familiar with all but the last two items on the list; Robot/Robot Controller and Vision Equipment.

Years ago you might have considered doing your own tune-up on a Dodge slant 6 engine; only a skilled and well trained auto mechanic should be working on today’s car engines with their high level of sensors and computer controls. Similarly, if you aren’t working with robots and their controllers and programming language on a daily basis, it is difficult to maintain the familiarity with them to be efficient working on them.

Robot Failure is Unlikely

The good news is that the most likely failure in your new robot cell will not be with the robot. In fact, with 80,000 to 100,000 hour mean time between failure (MTBF) for the most recent models of FANUC robot equipment, there is little to worry about over the life of the robot as long as your integrator or you have applied it properly (proper load capacity etc…).

If you do have a robot/controller related failure, your best line of response is going to be a trusted robot service partner ideally one who has experience with your particular robot cell(s) or at least with robot cells performing similar tasks. If you have a limited number of robots in your plant or facility you will likely find it difficult to maintain sufficient experience/training to change out robot drives, replace wiring harnesses (a common task after 7 to 10 years of use), and do other diagnostics/support on the robot and controller. A good, respected robot service provider will typically be in/out in a day and will always charge a reasonable amount for this type of service work. Look for a Level 4 Certified Servicing Integrator designation for FANUC robot service providers.

Remote Service Options

Reputable integrators will provide service options for their cells after install. We have a variety of service packages that allow our customers to have a carefree feeling that their system will be up and running quickly no matter when they have an issue. MCRI offers a variety of Remote and PM Service packages for our customer and we provide 24/7 service to these customers.

If you have internet access on your factory floor, some robot integrators and most OEM manufacturers will have remote internet diagnostics. Keep in mind, however, that if you purchase your robot cell from an integrator you will want to contact the integrator for support rather than the robot’s manufacturer. The OEM supplier of the cell will have no documentation on any portion of the robot cell except for the robot itself. This is why it is so important to ensure that your integrator (or OEM) will be able to support you during any time your factory is in operation. If you are running a 24×7 operation, make sure your integrator will provide a phone number for a technical contact 24/7.

Other Equipment Issues

More likely failures will be with other equipment that is typically simpler to diagnose and troubleshoot – such as limit switch or photo cell failures, or switch/photo cell being out of adjustment, end-of-arm tool mechanism failing or being bent/broken due to mishandled part or part out of tolerance, and input or output card failure. The trickiest failure mode is typically faulty wiring due to wear and tear from repeated flexing. Wires will fatigue and eventually break, most commonly at connection points. These failures can be intermittent and therefore difficult to diagnose and locate.

Robotic Palletizing Cells – Question 4

Will you train our operators, and how much training will they get?

We supply as much training as you require in order to confidently operate your new robotic work cell.

Customer training for both maintenance and operation is part of every Motion Controls Robotics supplied robot work cell and this should be a priority for you when selecting an integrator.

Your operations and maintenance personnel will have the option of doing the training at our plant in Fremont, OH or at your site, or a combination of these two locations.

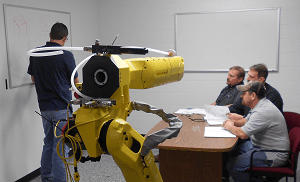

MCRI has a specially configured training room and customer solution center adjacent to our manufacturing floor in Fremont, OH where a robot and controller can be brought in to allow for training. Hands-on training, often the best form of training, is typically initially provided on your work cell at the completion of setup/testing at our plant, or after it has been set up again at your plant, just before start of production. Additional hands-on training is frequently provided during initial production startup while we are providing startup support for the cell.

Formal classroom training is commonly provided in our classroom and/or in a classroom setting you would supply at your plant site. The training focuses on the following areas:

- Startup procedure(s)

- Operation of robot, end of arm tool, conveyor and other equipment as applicable

- Error recovery procedure(s) with focus on quick recovery techniques – where they can be used

- Special PLC logic in the robot cell, if applicable

- Safety provisions of the robot work cell

Duration of the training is dependent on the project complexity but typically lasts from 8 to 24 hours of classroom and hands-on time.

Learning a new technology can be challenging, even for the most gifted students. It is not uncommon for new customer maintenance or operations people to require additional support with a new robot cell in the first 2-3 months of operation in spite of well attended training sessions.

For a limited time immediately following installation and startup of a new robotic palletizing cell or other robotic work cell, Motion Controls Robotics provides additional support at no charge to you – 24/7. Should there be a need for additional formal training; MCRI will provide additional training at our regular published training support rates.

As a Level 4 Certified Servicing Integrator for FANUC Robotics, MCRI is able to provide training classes for any FANUC robot or controller and will even provide training for FANUC robots supplied by other integrators. Contact us for additional information and a quote on a robot training class configured to your specific needs.

Conclusion: Embrace the Future of Robotic Excellence

Embarking on the journey of incorporating robotic palletizing cells into your manufacturing and warehousing operations marks your pursuit of efficiency and innovation. At MCRI Robotics, we understand that first-time purchasers often grapple with insightful questions as they start their first project. We hope the insights shared here have armed you with the knowledge and confidence needed to move forward with your automation ideas.

The safety of your robotic palletizing cell is paramount, and understanding the safety system layout ensures a secure working environment. As technology evolves, so do safety standards; hence, periodic reviews of your safety equipment design are a proactive approach to staying abreast of the latest guidelines.

Concerns about the longevity of your robot are valid, but rest assured that advancements in design and meticulous preventive maintenance can ensure your robot’s robust performance for a remarkable 10 to 20 years. Delve into the nuances of product weight, inertia, and duty cycle to optimize your robot’s lifespan.

In the unlikely event of a robotic palletizing cell issue, be it equipment failure or necessary program adjustments, our commitment to your success extends beyond installation. Our Level 4 Certified Servicing Integrator designation ensures you have a trusted partner for prompt, reliable service and support.

Training is not just a part of our process; it’s a commitment to give your team the skills needed to operate your robotic work cell. From hands-on sessions to comprehensive classroom training, we prioritize your proficiency and provide additional support post-installation.

As you start your robotic journey, know that MCRI Robotics is here to guide you through every step. Embrace the future of robotic excellence, and let your facility ride the wave of automation that is reshaping manufacturing and warehousing.