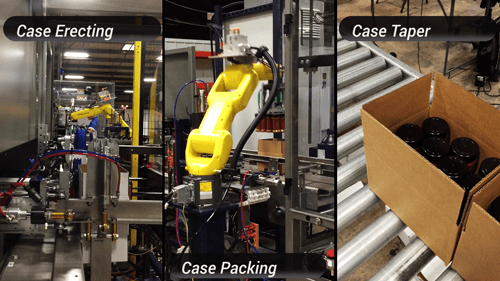

Robotic Case Packing Overview

Motion Controls Robotics latest integration project was a robotic case packing system for a customer in the food and beverage industry. We recently designed and installed a single line palletizing system for this customer. We described the single line robotic palletizer in a previous article where we showed a system for palletizing wrapped product. The company needed to change part of the process and start packing the product into cases. So, we reprogrammed the system to handle cases, and added a case packing robot to the front end. The whole process is now automated by using an additional case erector and a case taper.

Customer Challenges – Robotic Case Packing System

The customer’s main goal was to be able to update their system to provide cases to customers instead of wrapped product. Our challenge in designing the system was to be able to keep a consistent rate of 200 bottles a minute with the different weights of the spice bottles. Spices like parsley can weigh as much as 8 times less than denser spices like garlic.

Case Packing Process

- The Combi 2-EZ®SB SIDE BELT DRIVE CASE ERECTOR WITH BOTTOM TAPER pulls a case from the magazine using a vacuum cup gripper. The case is erected and sent through the bottom taper.

- Cases continue down the conveyor parallel to the inline conveyor for the spices.

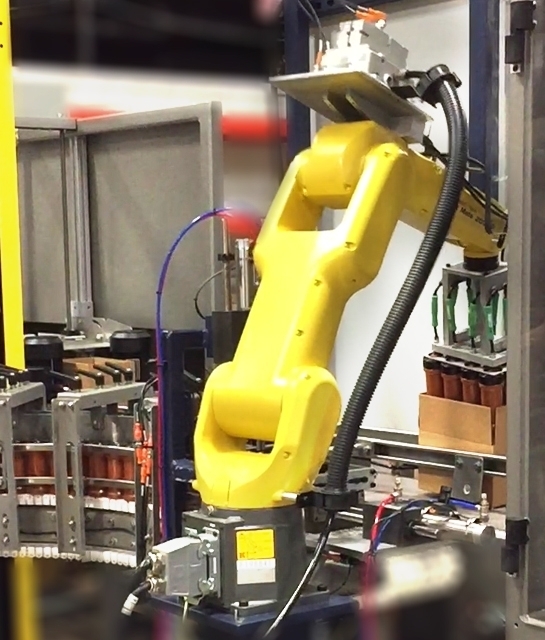

- The spice bottles move into the pick registration device where the robot picks 12 spice bottles from the pick area.

- The robot places the spice bottles in the case at a diagonal position to keep flaps out of the way.

- The case is sent down to the next stage to the Combi Case Sealer to tape the top flaps.

- The case continues on the conveyor and around to the single line case palletizer.

- Finally, the R1000iA 80H FANUC robot palletizes the cases of spice. When the pallet has been filled with each particular spice the pallet is moved out of the system and a new spice can start going through the system.

Robot and End of Arm Tool

For this case packing application, we selected to use an LR Mate 200iD 7L. This model has a longer reach and was able to meet the rate requested by the customer for packing their product as it comes into the cell. The End of Arm Tooling (EOAT) was specially designed for this product that has a standard lid size. The EOAT has inline vacuum generators that pick the product to place them in the case.

LR Mate 200iD 7L

- AXIS ROBOT – 6

- REACH – 911 mm

- LOAD CAPACITY – 7 kg

Safety Features

Motion Controls Robotics follows the RIA 15.06-2012 Safety Standard designed to make sure employees and robots work safely together. We take full advantage of new technologies and innovations available. Each system is complete with safety fencing and cell entry gates equipped with safety interlock switches.

Customer Results

This food customer was very happy with their fully automated system that can erect cases, pack spices into the cases, and seal cases for robotic palletizing.

If your company has a process that needs robotic case packing and palletizing, contact Motion Controls Robotics to get a quote. We a variety of examples and experiences in designing robotic packing and palletizing systems. We also work closely with Combi Packaging Systems to provide the fully automated systems through the addition of case erectors and sealers. These are all common needs companies are looking to add to their facility.