Advanced Robotic Case Erector for Random Case Sizes

Case erectors are an automated end of line packaging solution that solve ergonomic issues where employees have to perform repetitive tasks. There are a variety of ways to setup a case erector to match your packaging process speed and needs. Adding a case erector can even save floorspace in certain situations.

What Type of Case Erector Do You Need?

Case erectors need to be seamlessly integrated into your total process.

Random Case Erector

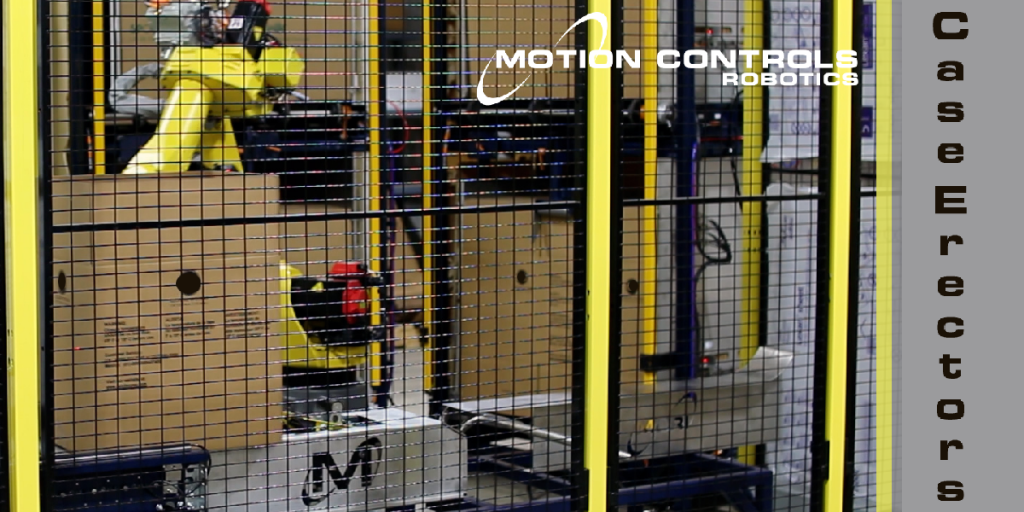

The random case erector pairs a FANUC M20iD or M10iD six-axis robot with multiple case magazines and a bottom flap folder with an integrated sealing head. The robot’s flexible end-of-arm tool picks and erects various case sizes, eliminating the need for changeover downtime. The standard setup includes three case magazines, but the system can be configured to handle additional case sizes for greater flexibility.

Inline Case Erectors

An inline case erector automates the process of assembling cases on a production line. Flat case blanks are fed into the machine, which picks and forms them into fully erected cases. These cases are then secured with adhesive or tape, ensuring they are ready for packing. The erected cases move directly onto a conveyor, seamlessly integrating into the packaging process. This system is ideal for high-speed operations, improving efficiency by reducing manual handling and ensuring consistent case quality throughout production.

Pick-Pack-Pal

For low-volume packaging processes, one or two robots can handle the entire operation. These cells are ideal for packing small items like pouches, food products, or other compact goods. The robot begins by erecting a case, which is placed on a conveyor for packing. Once filled, the case is sealed and palletized. The pallet can either be manually removed or automatically supplied by a pallet dispenser and exit conveyor.

![]()

Case Erector Add-ons

- Ethernet connectivity for automatic case size selection, and for remote diagnostics and support

- Additional case magazines

- High speed bottom sealing with servo adjustable side belts for increased speed

- Larger and smaller case sizes available on request

- Two magazine set-up for no-change over case erector

The random case erector robot cell can be adjusted to fit the needs of your application.

A recently installed random robotic case erector replaced the space of four traditional case erectors. When a specific case size is needed, a signal is sent to the robot, which then builds the required number of cases. The completed cases are transported to the packaging area using one of the facility’s AGVs, streamlining the process and optimizing space efficiency.