In the manufacturing industry, needing to handle trays, whether they are plastic or cardboard, is a common occurrence.

Incorporating robotics for tray handling offers advantages that enhance productivity, safety, and efficiency. This article and accompanied video show how facilities in a variety of industries are using robotics to handle and move trays throughout their facility. This has led to numerous benefits these facilities’ plant managers and engineers are seeing.

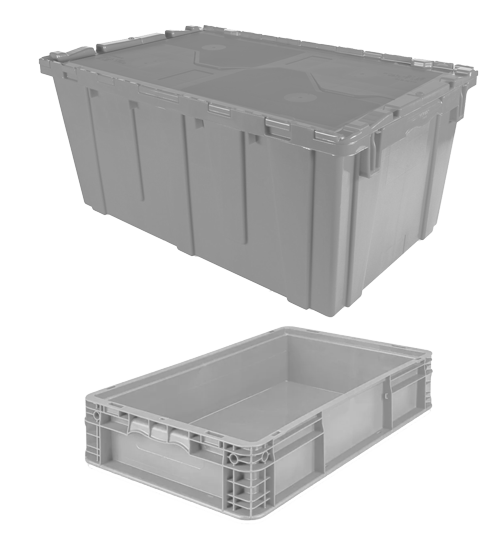

Before we dive into the benefits and applications of robotic tray handling, there are similar robotic applications for both tray and tote (bin) handling, but this article focuses on robotic tray handling. What do we see as the difference?

Whether “totes” or “trays” are used depends on the specific application within the manufacturing and warehouse environment. Trays are generally used for lighter, flatter items requiring precise handling, while totes are used for bulkier items or higher volume transport and storage. Both options provide significant benefits when integrated with robotic systems, enhancing efficiency, safety, and operational flexibility.

Knockout Inefficiencies with Robotic Tray Handling

Now that we have that cleared up let’s take a look at the 6 main applications where we are integrating robotics for tray handling:

Storage

Automated tray stacking systems can be running continuously. Taking trays from conveyors and entering them back into production as needed. Stacking trays efficiently maximizes storage space and ensures stability. Adding robotics in stacking applications also minimize the risk of worker injury from repetitive, mundane tasks.

Packing/Unpacking

Robotic systems can handle overflow situations by automatically redistributing trays to secondary storage areas or production lines. This ensures that production continues smoothly. By managing overflow efficiently, robots help maintain a balanced workflow and prevent bottlenecks in the production process.

Palletizing

Automated systems transport trays throughout the facility via conveyors, reducing the need for forklift traffic. This increases efficiency by ensuring a continuous flow of materials and enhances safety by minimizing worker interaction with forklifts. Automated tray conveying supports a more organized production environment.

Stacking

Automated tray stacking systems can be running continuously. Taking trays from conveyors and entering them back into production as needed. Stacking trays efficiently maximizes storage space and ensures stability. Adding robotics in stacking applications also minimize the risk of worker injury from repetitive, mundane tasks.

Overflow Management

Robotic systems can handle overflow situations by automatically redistributing trays to secondary storage areas or production lines. This ensures that production continues smoothly. By managing overflow efficiently, robots help maintain a balanced workflow and prevent bottlenecks in the production process.

Conveying

Automated systems transport trays throughout the facility via conveyors, reducing the need for forklift traffic. This increases efficiency by ensuring a continuous flow of materials and enhances safety by minimizing worker interaction with forklifts. Automated tray conveying supports a more organized production environment.

Benefits of Robotic Tray Handling

As mentioned previously, facilities that are integrating robotic tray handling are seeing a variety of benefits and are moving forward with automating all tray handling in their facilities. Here are the 6 benefits of robotic tray handling.

- Cost Savings

Long-term cost savings are significant. By automating tray handling tasks, manufacturers can reduce labor costs, minimize downtime, and increase throughput. Additionally, robots can help facilities deal with labor shortages and reduce the reliance on temporary or seasonal workers, providing a more stable and predictable workforce.

- Increased Productivity and Efficiency

Robots can perform repetitive tasks with high precision and speed. This leads to a significant increase in productivity as robots operate continuously without breaks or fatigue. For instance, they can efficiently move trays from conveyors to racks and vice versa, ensuring a smooth and uninterrupted workflow throughout the production process.

- Enhanced Worker Safety

One of the primary benefits of using robotics for tray handling is workplace safety. Robots are designed to handle tasks that are hazardous, tedious, or ergonomically challenging for human workers. By automating these tasks, robots reduce the risk of workplace injuries associated with repetitive strain and heavy lifting. This not only protects workers but also decreases the costs related to workplace accidents and health insurance.

- Flexibility and Versatility

Robotic systems are highly adaptable and can be customized to meet specific requirements. They can be equipped with various end-effectors to handle different types, shapes, and sizes of trays and products.

- Consistent Quality and Reliability

Robots ensure every tray is handled with the same level of precision. This consistency is crucial for maintaining high standards of product quality and reducing the likelihood of errors. Automated systems can also integrate with vision-guided technology and tracking software like ImpactIQ to enhance accuracy in sorting and placing items.

- Improved Employee Engagement

By eliminating the need for employees to perform monotonous and physically demanding tasks, robots can improve overall employee engagement. Workers can be redeployed to more value-added roles, enhancing job satisfaction and reducing turnover rates. This not only benefits the employees but also contributes to a more dynamic and productive work environment.

Robotic Tray Handling – the Conclusion

Implementing robotics for tray handling offers numerous benefits that can transform your manufacturing operations too. From increasing productivity and safety to providing flexibility and cost savings, robots are an asset for modern manufacturing facilities.

By embracing robotic automation, you can stay competitive, meet changing demands, and build a safer and more efficient workplace. Contact MCRI to start asking questions about your tray handling options.