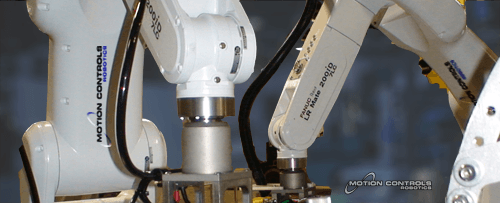

When developing an automation system, many times floor space restrictions require the use of multiple robots in a common work envelope. This creates the potential for robot collisions or deadlocks, neither of which is acceptable. Deadlocking instances cause downtime and decrease productivity. Robot collisions can damage or destroy equipment.

Fanuc’s R30iB Robot Platform provides software for “Intelligent Interference Check” (IIC). This IIC software works with robots running on the same controller or connected through Ethernet to avoid collisions and increase robot density in a specific work area.

The IIC software can be programmed to avoid fixtures, machines, and other robots. It is designed to analyze routines and input instructions or macros that ensure avoidances that deadlock a system. The software also includes Railcheck to distribute these same benefits to automation systems where robots are running on a rail.

Features of Intelligent Interference Check include:

- Preprogrammed modeling for fixtures, machines, and machine door open/close

- IIC data can be easily transferred from Dual Safety Check (DSC), another controller or .xml files

- iPendant or an HMI terminal can be used for setup and recovery

To learn more about FANUC’s latest generation robot controller and how it can improve your robot application, you can download the data sheet above. This PDF contains information on all features included as well as specifications. If you would like further information contact our sales group.