FANUC’s iRVision is the only fully integrated vision system available in the robotics industry. iRVision is one of the many features and tools available from FANUC, the #1 choice of customers worldwide.

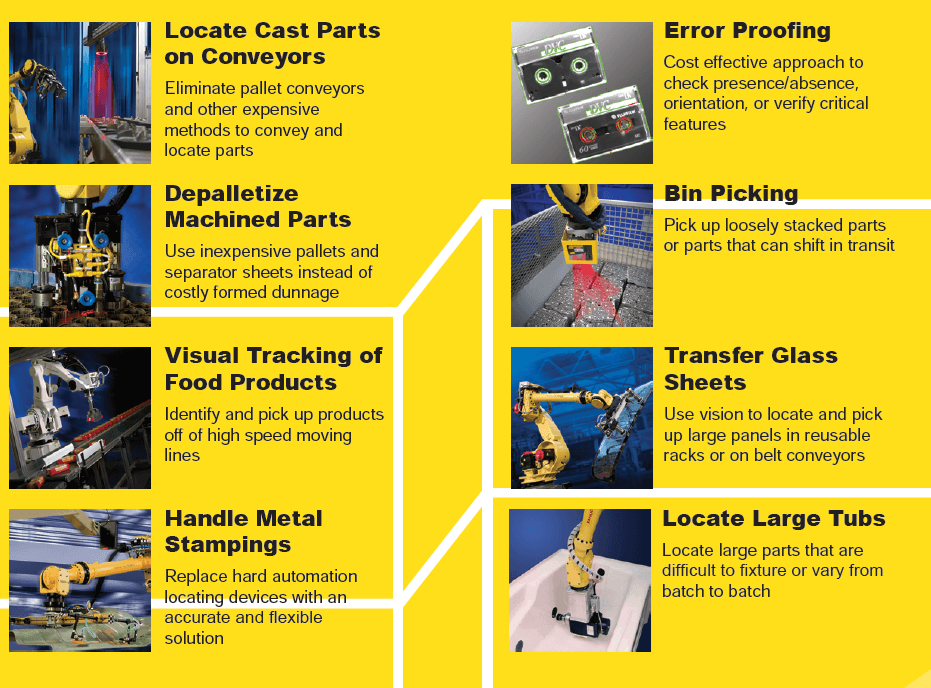

Common uses of Integrated iRVision System include:

Below are 12 of many reasons that iRVision should be your robot vision system of choice:

-

- “Snap on the Fly”

- FANUC robots using the Integrated iRVision System always know where the camera (or part) is when an image is taken, an accurate cycle time saving position can be determined. No other robot vision system can do this.

- 3DL Vision processes

- Built-in tools and capabilities to locate parts with varying physical levels and poses, as you might find with random parts laying in a bin

- MultiView vision processes.

- Complicated robot math calculations and formulas are included inside the MultiView vision processes that save engineering time in not having to “figure out” the math.

- Easy and accurate vision to robot calibration.

- Both standard grid calibration, as well as fully automatic self calibration methods are provided.

- Improved application accuracy is achieved when iRVision is used to generate user Frames and Utools.

- “Snap on the Fly”

-

- iRVision is the robotics industry’s only vertically integrated single source vision guidance and inspection package on the market, with over 27 years of application experience and sales success. Single source supply eliminates headaches for the end customer.

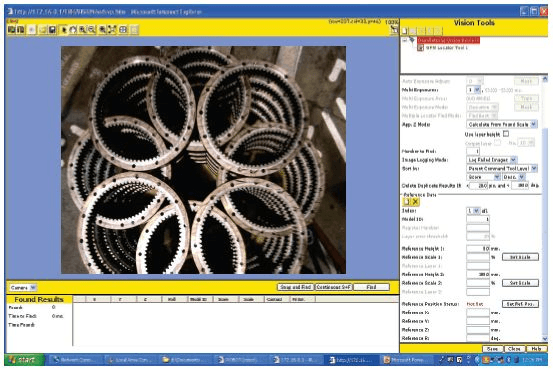

- Advanced GPM (Geometric Pattern Matching). With the unique FANUC emphasis in this area, iRVision is exceptional to other geometrically based vision model capabilities.

- Factory certified and warranted cabling solutions are available with integrated vision cables in most all robot mechanical units as standard.

- iRVision’s design is focused on providing the right solution to real-life robot applications – based on the largest installed robot base in the world.

- Easy to setup and use – saves time and money setting up your vision process.

- Prepackaged interface between robot function and vision function simplifies programming, reducing total solution cost and reducing lead time.

- One Stop Shopping

- Lights, cameras, and software all from the same place you purchase your robot

- Single point of support

- Provides seamless Integration

Contact a Motion Controls Robotics, Inc. sales engineer at 419.334.5886 to determine if iRVision is the right solution for part position sensing, quality inspection, error detection, line tracking, measurement, or other possible vision application.