The M-Tablet – Motion Controls Robotics’ Portable HMI

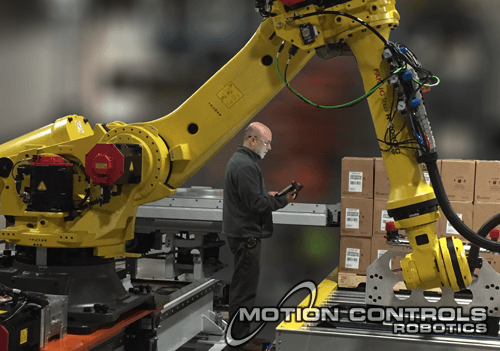

The HMI in a robot system is used by the operator to interact, setup and gain important information about the production process. Adding a portable HMI simplifies that process by allowing the operator mobility throughout the system to input and gather information or troubleshoot issues.

MCRI’s M-Tablet is a portable HMI used to interact with the robot system in a variety of ways. This tablet features a 10 inch touchscreen protected with a drop resistant case. The case is also IP65 dust and water rated. The screen has high brightness and reduced reflection and glare, so it is easier to read in all lighting conditions. There are a variety of setup options available to customize each tablet.

The M-Tablet operates using the same interface as the regular HMI, but also offers the functionality of a PC. The M-Tablet is perfect for large robot cells where there are numerous robots that are running a variety of lines. This type of setup is common in robotic unitizing or distribution systems.

Benefits of using a the M-Tablet portable HMI in your system:

- Unobscured view of system during operation

- Increased production time by minimizing walk time from one area to another

- Eliminates need for multiple standard HMIs which can become cost prohibitive

- Localized troubleshooting of processes and I/O

- The M-Tablet is perfect for managers to use for Dashboarding during production meetings (sharing specific production information)

- PLC and Robot diagnostic operations such as Fanuc’s iRDiagnostics, Roboguide, and PalletTool

- PLC and robot programming software can be loaded on the portable HMI

- Ability to run Rockwell’s Logix5 and Panelview Plus software

- If your system is very large, the on-board GPS enables the ability for screens to auto adapt to the location and production line where you are standing

MCRI’s M-Tablet also offers a variety of integration options such as GPS, Barcode, Magstripe, and RFID readers. Adding these options, along with MCRI’s custom database integration software, increases the functionality of the M-Tablet.

Magstripe reader

Operators are often required to have identification badges during time on the floor. By adding a Magstripe reader to your M-Tablet, operators can swipe their badge to login to the system. This login makes the system more secure. It can also trigger a recording of actions taken while logged in for future troubleshooting or reference.

Barcode Scanning

The integrated barcode scanner quickly reads barcodes in a variety of lighting conditions making it easy to scan boxes on the conveyor. The barcode scanner can be used to input information into the HMI. We then develop customer applications that will interface with plant databases and ERP systems (SAP, QAD, etc) making production information and scheduling more accurate.

An example use of barcode scanning is setting up the next product run and pallet setup. The Pallet Build screen on the HMI allows the operator to select the specific line in a multi-line system. The HMI shows the line selected and the pallet data for that line. Once the layer count and tier sheet locations for the scanned product are selected the information is saved to a database. The video below show how this works.

RFID Readers

If your plant has implemented the use of RFID chips this reader can be used similarly to the barcode scanner.

The M-Tablet offers options for batteries that last up to 16 hours. Backup batteries can also be purchased. The M-Tablet can have several docking stations equipped with E-stop areas and for charging.

If improving the mobility of your operators would increase your production efficiency and output, Motion Controls Robotics can integrate an M-Tablet portable HMI into your current or new robot system. Robotics Contact Form