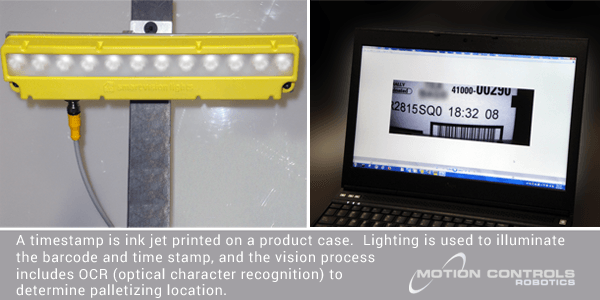

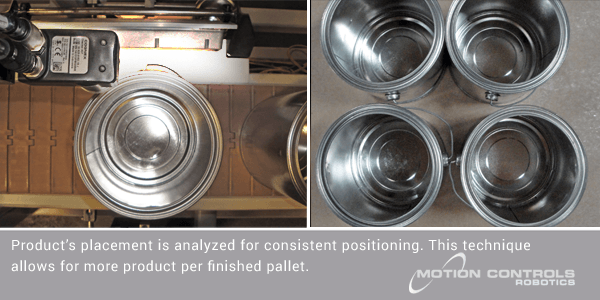

Lighting can be used in different ways to compliment machine vision applications. The most common application is creating proper contrast for inspection or position locating operations. Lighting is also important in barcode and optical character recognition (OCR) to maintain appropriate illumination for optimal camera focus.

An automation system may contain several vision stations throughout the process each having different goals. Once each vision application is decided, then the lighting options need to be evaluated.

Choose a type of light that best suites the application

Halogen or Fluorescent Lighting (Traditional)

| Pros | Cons |

| Light large areas | Lighting intensity degrades over time, affecting vision performance |

| Inexpensive hardware | High power consumption |

| Readily available | Possible electromagnetic interference (EMI) issues with fluorescent lights |

| High intensity (bright) | Pulsing characteristic caused by the 50Hz or 60Hz AC voltage may cause flickering during image acquisition |

| If the light is triggered during inspection, it may take time to reach its full brightness |

LED Lighting

| Pros | Cons |

| Many colors (wavelengths) available | Expensive compared to traditional lighting |

| Low power consumption | Usually suited for small area illumination |

| Short time to reach full brightness | |

| Long lasting and stable intensity | |

| No electromagnetic interference (EMI) | |

| No issues with frequency pulsing |

At MCRI, we use SmartVision Lights for our machine vision applications. SmartVision Lights has a wide range of lighting options for application flexibilty. Over the next few weeks MCRI will be helping you to explore each category of basic machine vision hardware. Next week we will be discussing machine vision filters. You will learn why filters are needed and how to select the best filter for your application. If you would like to learn more about Basic Machine Vision Hardware, contact our sales group.