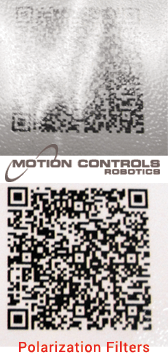

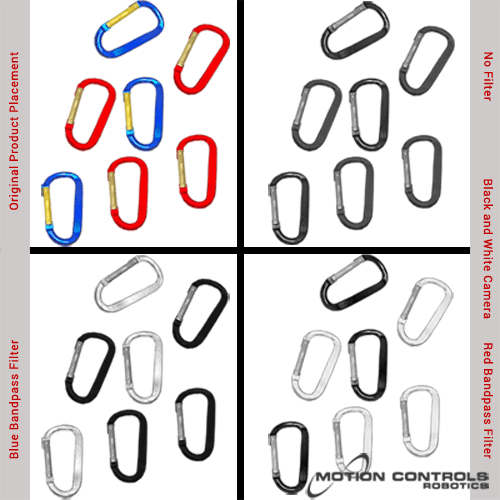

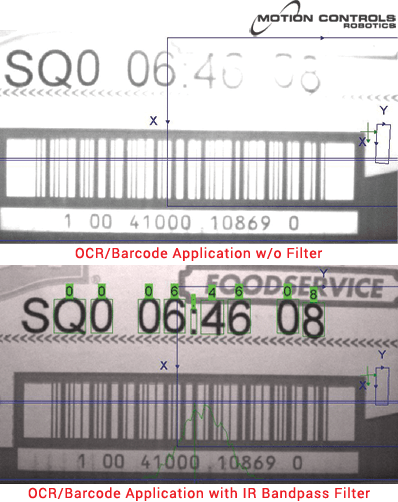

Proper robotic vision filter selection further facilitates keying in on specific aspects in the vision application related to contrast. While proper lighting is important, ambient light can cause glare and contrast issues. Using filters can alleviate these issues and simplify the vision process. Bandpass filters are also used to highlight or remove color on the product while still using black and white cameras. Polarizing filters are useful for reducing glare and spotting surface defects on products.

The goal when selecting a proper filter for an application is knowing current lighting conditions and if they will diminish the effectiveness of the process. It is important to select filters that provide you with the best image for all of the production parts.

Select a robotic vision filter based on application purpose

Color Bandpass Filters

| Pros | Cons |

| Blocks specific visible wavelengths of light | The lighting resides in the visible spectrum so ambient light can still play a role since it is difficult to block all visible light |

| Improves contrast by focusing only on specific wavelength, blocking the rest | Since it is used with lighting in the visible spectrum it is seen by the human eye and flashing lights can cause safety issues when used in employee production areas

|

IR Bandpass Filters

| Pros | Cons |

| Blocks UV and Visible light, eliminating unwanted ambient lighting | Cannot be used with color cameras |

| Can be effective in penetrating certain materials (packaging materials) | |

| Great at diminishing grayscale differences in colored objects | |

| Cannot be seen by the human eye so it will not affect employees on the production floor | |

|

|

Polarization Filers

| Pros | Cons |

| Greatly reduces glare issues | Filter position is very important and can dramatically affect results. |

Over the next few weeks MCRI will continue to help you explore each category of Basic Machine Vision Hardware. Next week we will be discussing vision system cameras. You will learn how to select a camera with proper resolution for your application. If you would like to learn more about Basic Machine Vision Hardware, contact our sales group.