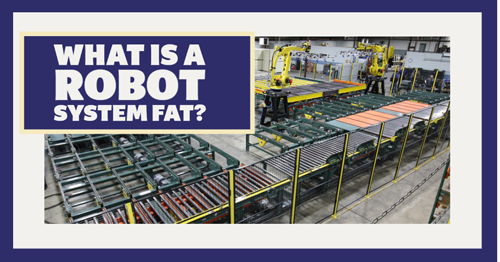

Robotic Board Handling

Polyiso Insulation Board

Are employee turnover and ergonomic issues in your polyiso insulating board product manufacturing and packaging lines causing you concerns? Motion Controls Robotics is the leading expert in robotic polyiso board handling with the largest installed base of systems throughout the country. We have developed a pre-engineered robotic polyiso board handling system to minimize production and packaging costs and improve quality for the manufacturers of building products. This robotic board handling system reduces production costs, eliminates ergonomic issues and allows for on-the-fly process adjustments. This proven system is also easy to use and install.

Motion Controls Robotics is the leading expert in robotic board handling with the largest installed base of systems throughout the country.

Material handling applications, like stacking flat products, can greatly benefits from the integration of robots into the

process. The main drivers for adding robotics are:

- a need for a safe work environment

- cost reduction

- consistent manufacturing rates

- increased quality through minimizing product damage

MCRI stacks other large, flat building and other products such as drywall, paneling, sheetrock, plywood, extruded plastic glass, and other specialty building products.

Reliability and Durability

- Provides proven performance – over 5.5 billion square feet of board have been reliably palletized

- Low maintenance state-of-the-art components

- Simple straightforward end-of-arm tooling

- Robust welded construction

- Automatically match robot speeds to production rate (to increase longevity of equipment)

Installation

- System can be fully operational in a week

Flexibility

- Handles sizes 4´ x 4´ through 4´ x 16´ typical

- Fast recipe based change over

- On-the-fly process adjustments

- Adjusts automatically for normal process variations

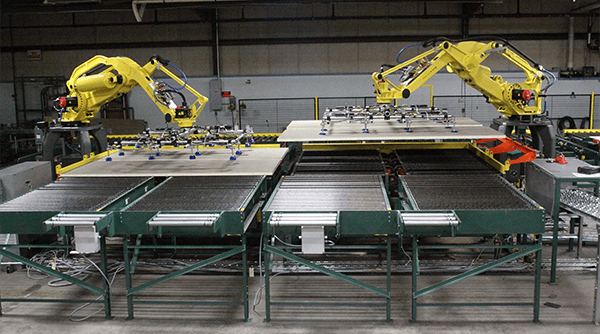

FANUC Board Handling Robots

Click on robot to learn more

Benefits

Production Cost and Risk Reduction

- Predictable performance

- Eliminates repetitive motion injuries

- Minimizes seasonal labor needs

- Improves overall product yield

- Allows optimization of production rates

Ease of Operation

- On demand reject handling and QC management

- Automatically rotate and invert product, as well as orient product taper

- Menu driven operator interface

- Graphic based diagnostics

- On-site and remote diagnostics

- Production statistics monitoring

- Control of upstream and downstream operations

Quality

- Reduces handling damages

- Improves stack consistency and accuracy