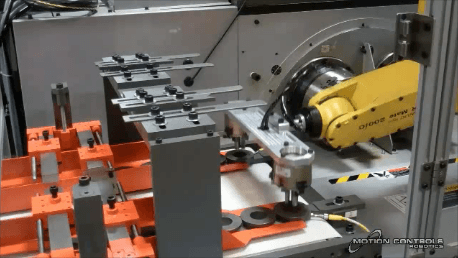

Robotic Machine Tending

Motion Controls Robotics can help you develop a system to automate general machine tending operations, improving your competitiveness. Motion Controls Robotics has developed and installed robotic machine tending systems in a wide variety of general material handling applications.

Parts may be fed to the machine(s) by flat top conveyor, lugged conveyor, in totes or in bins, or placed onto simple gravity feed conveyor. Likewise, finished parts can be placed onto a wide variety of conveyor or into bins or totes when completed in the work cell. Parts can be stacked up for a shift or more of operations before, and after the robotic work cell.

These systems work without any team member involvement through a night shift, or over the weekend.

Benefits

Increased throughput

- Unattended production

- High reliability and uptime with 80,000 to 100,000 hours mean time between failures on new FANUC robots

- Labor savings

- Reduces worker compensation costs and improves ergonomics

Flexible and precise

- Vision system eliminates process variables, provides integrated error checking

- Precise, 6-axis servo-controlled system

- Quick changeover using quick change tooling and stored recipes

Programmable

- Built-in operator pendant with stored recipes

- Menu selection for patterns

- Process adjustments on-the-fly

- Stores recipes and allows for easy retrieval

Increased quality

- Reduces handling damage and scrap

- Improves product consistency and accuracy

- Vision to inspect product before and after assembly – 100% inspection