BA Palletizer - Portable & Collaborative Station

Cobot Palletizer

The BA Palletizer features a FANUC CRX-25iA collaborative robot. These compact palletizing stations save floorspace and are easy to install and program. Area scanners allow full speed palletizing without additional barriers and upon detecting operators the station slows/stops to keep operators safe as they approach or replace full pallets. Being portable to other locations in the facility is a breeze with fork pockets and leveling pads integrated into the base for easy transportation and setup.

BA Palletizer Features:

End of Line Palletizing

Collaborative, End of Line Palletizer for use with multiple lines without extended downtime or setup costs. The station contains 2 pallet stations for different product/orders or case size. The low initial investment of these robotic systems makes it easy for any company to add a new system, and experience a quick return on investment.

FANUC CRX-25iA Collaborative Robot

The FANUC CRX-25iA brings reliability, quick setup, and easy programming to collaborative robots. The lightweight robot comes with the R-30iB Mini Plus Controller. FANUC Collaborative robots include 8 years with zero maintenance as well as their proven industrial reliability. You will know how important this aspect is if you have used other brands of cobots in the past.

Compact Footprint & Portable

This station is designed to be compact offering optional onboard air and controller. There are fork pockets and leveling pads integrated into the base for easy transportation and setup. All FANUC CRX models use a standard outlet, so this palletizing station can be plugged into any regular outlet.

Easy Setup

Using the tablet’s 3D Layer Building program, new product and palletizing setup can be done in minutes and the robot can start palletizing.

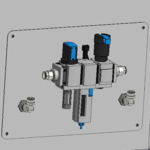

Gripper

There are a variety of options for the gripper from custom designed to off the shelf. One gripper that works with collaborative applications is the Schmalz Vacuum Gripper. View more about the Schmalz Gripper

Contact MCRI to find out how to save 25K on your BAP.

Low Risk – Low Initial Investment Automation

Cobot Palletizer - Specifications

Cases

A variety of case sizes can be run using the BAP.

– Up to 8 robot cycles per minute

Stack Height

The palletizer can be setup with a lift to accommodate taller stacks.

– Fixed Base: 68”

Power Requirement

The BAP Station can be plugged into any regular 120 VAC outlet.

– 120 VAC / 20 Amp / 60 Hz

Optional Air Capacity

Plug in 1/2″ air hose and you are good to go. No air lubrication required.

– 1/2″ Line (Push-To-Connect)

– 14 CFM @ 80 PSI

Pallet Information

The BAP can palletize to two different pallet stations.

– Any 40” x 48” Pallet: GMA, CHEP, PECO, iGPS

Tier Sheet

You can add an optional tier sheet stand if the inbound conveyor allows.

– Tier sheet stand can be added

Station Safety

Motion Controls Robotics follows the ANSI/RIA R15.06-2012 Safety Standard designed to ensure employees and robots work safely together. We take full advantage of new safety technologies and innovations as they become available.

– Area scanners included

– Collaborative robot

– Safety risk assessment recommended

Purchase & RaaS Options

The BA Palletizers are here! Get in line today for the BA palletizer!

RaaS

– The BAP is a perfect RaaS station for introduction to Robots as a Service.

Purchase Options

– 1 day with MCRI – setup & training on the BA Palletizer

– Purchase the system and get started