Counterbalance Fork AGV

Downloads for the various Counterbalance Fork AGV Models

Description

A Counterbalance Fork AGV (Automated Guided Vehicle) is designed for material handling and transportation tasks, where traditional forklifts are currently used. The “counterbalance” part of the name refers to the design of the AGV, which includes counterweight systems to balance the load, similar to traditional forklifts.

Key Features of Counterbalance Fork AGV:

- Load Handling: AGV counterbalance forks are equipped with forks similar to those on traditional forklifts. These forks are used to lift, transport, and place palletized loads, materials, or goods.

- Counterweight: To maintain stability and prevent the AGV from tipping over when lifting heavy loads, counterbalance AGVs are designed with built-in counterweights. These counterweights are strategically placed on the vehicle to balance the weight of the load being lifted by the forks.

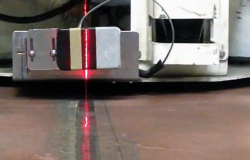

- Autonomous Navigation: The counterbalance forks are autonomous vehicles that can navigate through a facility or warehouse without human intervention, but we also offer the option of manually driving the AGVs. They use various guidance systems, such as laser guidance, magnets, Natural Feature Navigation, and Inertial Navigation technologies, to follow paths, markers, or predefined routes.

- Safety Features: AGV counterbalance forks are equipped with advanced safety features, including 4 safety sensors that can detect obstacles, people, or other vehicles in their path. They have collision avoidance systems to prevent accidents and ensure the safety of both equipment and personnel.

- Efficiency: These AGVs are known for their efficiency in material handling. They are battery powered and can operate continuously, 24/7, ensuring consistent and precise transportation of goods. This efficiency can lead to improved productivity and throughput in a facility.

- Customization: AGV counterbalance forks can be customized to handle various types of loads, including pallets of different sizes and configurations. The lifting capacity and height can also be tailored to the specific needs of a facility.

Applications:

AGV counterbalance forks are commonly used in manufacturing facilities, warehouses, and distribution centers for tasks such as:

- Transporting pallets of raw materials to production lines.

- Moving finished products to storage or shipping areas.

- Handling heavy or bulky materials within a facility.

- Loading and unloading trucks and containers.

- These AGVs are particularly valuable in environments where space is limited, and there is a need for efficient, precise, and safe material handling. By automating these tasks, AGV counterbalance forks can help reduce labor costs, improve material flow, and enhance overall operational efficiency.