Medical and Healthcare Robotic Systems

Robotics for the medical industry are the perfect solution to keep your process clean, flexible, consistent, and ergonomic.

- Flexible processes for sorting, packing, labeling, and palletizing a variety of products. Robots also allow for the flexibility to scale your process by redeploying robots.

- Consistent Processes with sensor, vision, weight, and other quality checks at each stage. Automating this process improves the total overall traceability of products.

- Easy to maintain a clean/sanitized environment

- Make workplace ergonomic by removing repetitive tasks and movements by adding cobots to work alongside employees to do such processes as loading and unloading trays from autoclaves or other sterilization equipment.

Robot Applications for Medical Industry

Robotic Labeling for Medical Industry

Dynamically Label Products, Pallets, and Cases

MCRI Offers database connectivity software called ImpactIQ. Combine this with barcode scanning for dynamically printed labels as well as product tracing for UDI labeling, 21 CFR Part 11 traceability, and verifiability compliance.

The systems shown above label product & pallets based on database information. Labels are applied using high-speed robots, automated in-line systems, and/or other robots for label application flexibility. The video below shows one a high speed labeling process.

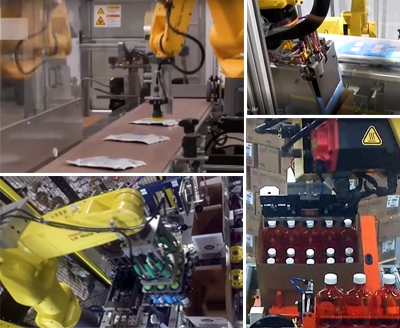

Case Packing for Medical Industry

Pack bags, bottles, and other product into cases for fulfillment

Starting the packing process with automated case handling options such as case erecting, sealing, and inspection. The product is then packed into cases or totes, inspected using vision and sensors, and sealed. Cases can then be dynamically labeled based on contents.

The above systems are packing a variety of products into cases – case packing options allow for flexibility in product size and count. Below is a video of an all in one system for packing and palletizing.

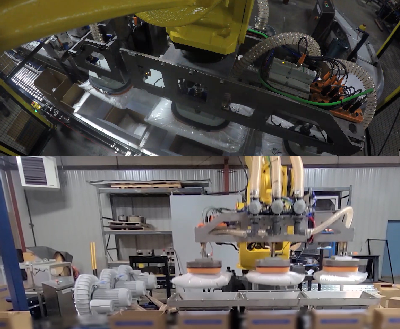

Robotic Picking & Sorting for Medical Industry

Build consistent trays or kits – pick correct supplies to add to cases

Robots can be used to sort products or pick products for specific kit or tray building. Product(s) can be placed in cases, totes, trays, or other containers. Trays can be loaded and unloaded for sanitizing.

The above system builds a kit by placing 2 blended bags, 1 plain bag, and a final small bag. Case weight is tested as well as a vision check to make sure all 4 bags are present in the kit. The below video is a tape inspection station which is another way to make sure your final product arrives safe and sound.

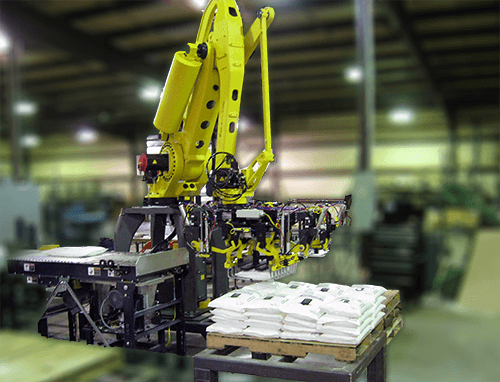

Robotic Palletizing for Medical Industry

The opportunities for palletizing are very flexible.

Based on your facility, you can have multiple, small one line palletizer throughout the plant, multiline palletizers, or centralized palletizing for increased efficiency. Palletizer can even handle different types of products for example the robot can change to a different product like palletizing cases and then drums on the same line/floorspace.

The system in this image is an example of flexible palletizing areas where not only cases are picked and palletized, but also drums are picked and placed.

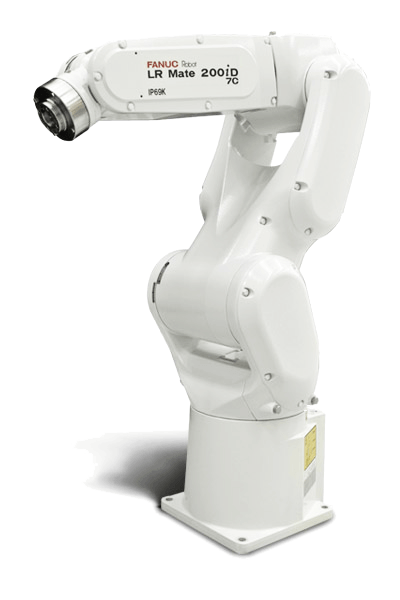

Robots for Medical Industry

There are a variety of robots for use in the clean room environment

Meet medical manufacturing standards while increasing productivity and efficiency

These Food Grade Robots:

- Meet IP67 standard

- Withstand harsh & corrosive environments

- Include vision inspection for quality traceability