High-Speed Picking Benefits:

- 3D and 2D vision bring adaptability and flexibility to the process.

- Decrease costs and ergonomic issues over human operation

- Increased production rates

- Higher quality product with the pinpoint accuracy available with high-speed robots

- Ability to add multiple robots in a small work area can more than double production while decreasing costs

- Customize production using vision and sensors

- Our systems meet RIA and ANSI safety requirements

- Applications for a variety of products, even fragile products

Adding high-speed applications to your facility brings increased flexibility and productivity to production lines. The lower cost and size of these systems means that many times companies will see payback in as little as one year.

High-speed applications:

- Picking – Vision finds any small part/product and moves part/product off of a conveyor to another location.

- Packing – Vision records product orientation and type (ie color, shape, size..) on a moving conveyor and robot places in trays, cases, pouches, or other packaging containers at high speed.

- Assembly – robot picks specific parts from the conveyor and assembles each part with precision on a moving workstation.

- Sorting – Through the use of vision, many parts coming by on a conveyor can be moved from one conveyor to another area. The product can also be sorted by color, shapes, or other vision use like quality controls where inspection is done to sort out any defective products.

- Labeling – Vision is used to find and orient a product, print a product-specific label, and apply the label. This process can be done at a rate of over 1 label a second.

Which are the main robots used for high-speed applications?

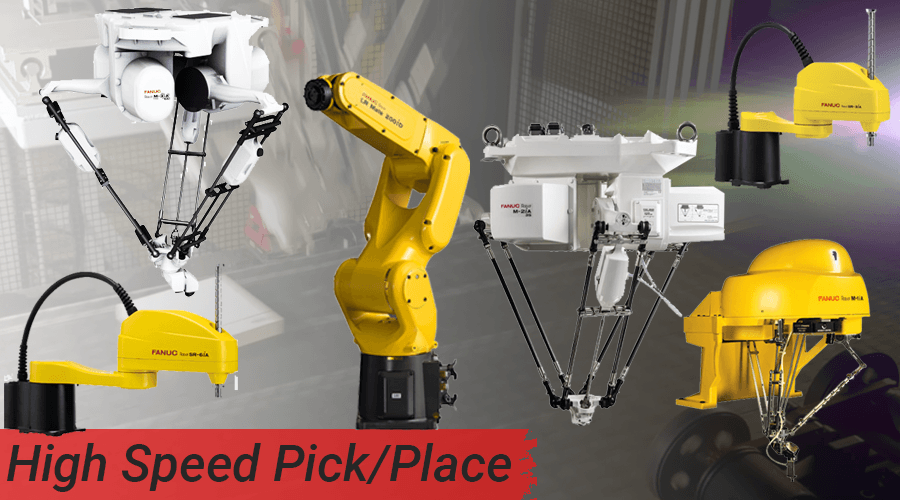

High-Speed Robot Options

FANUC has a wide choice of high-speed options so that the perfect robot for each application can be selected. All the robots are lightweight and compact allowing for a small workspace. The available high-speed robots have flexible installation orientation and a variety of axis options. High-speed robots can be used in food grade environments and are able to withstand high-pressure steam cleaning -IP69K rating.

Robots typically used for High-Speed Picking & Placing High-speed systems combine robots, conveyors, workstations, vision, and sensors interacting together for the most efficient process. The robots above are combined with sensors and vision to customize the overall process to meet production and quality needs. Conveyors can be set up to flow parallel, perpendicular or parallel counter depending on which flow maximizes the robot(s)’s speed.

High-Speed Industries

- Food & Beverage Industry – both raw and processed

- Packaged Goods

- Electronics