AGV Tuggers

AGV Tugger Models Available:

- M10K-T

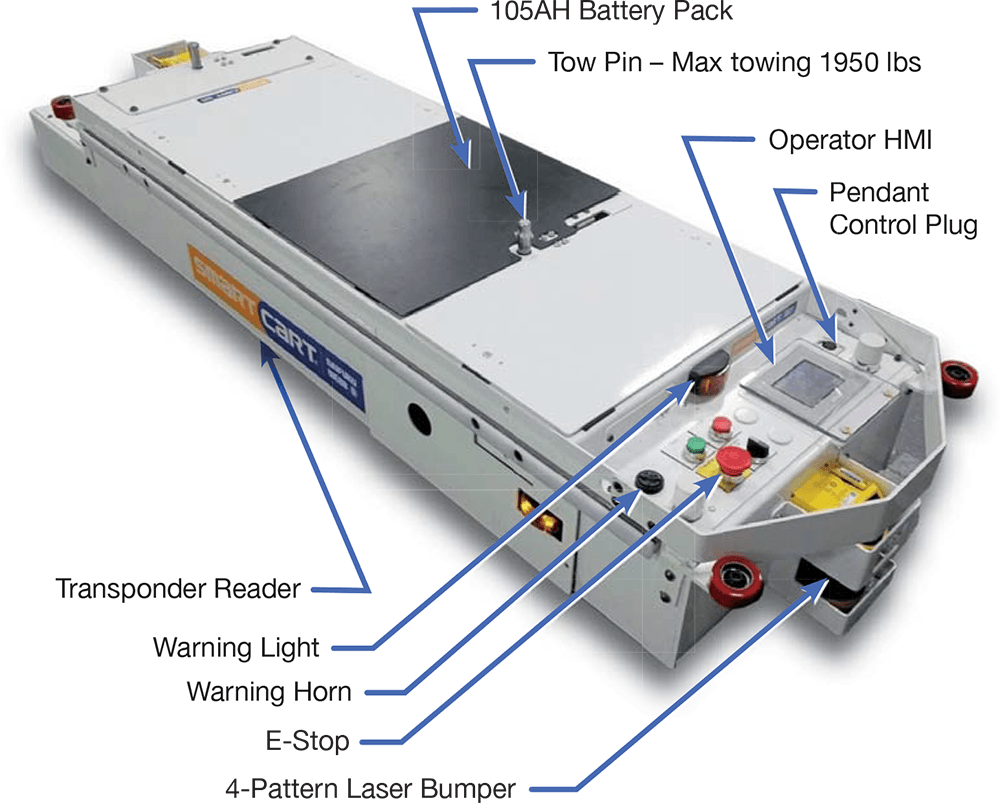

- M100-TT

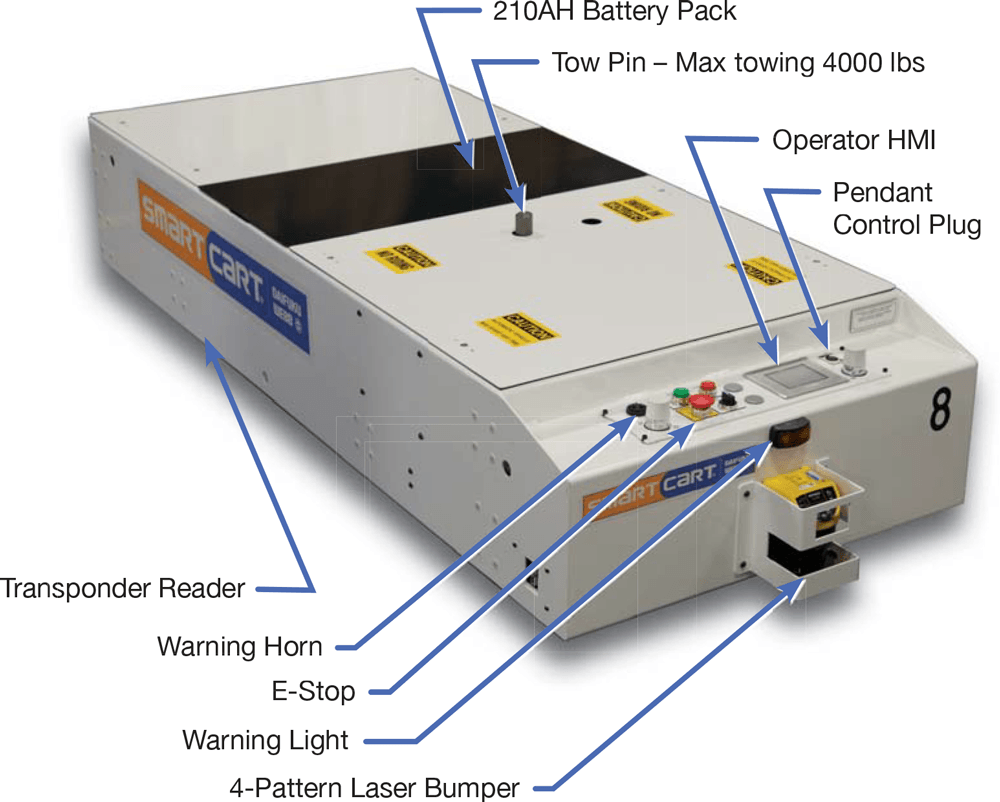

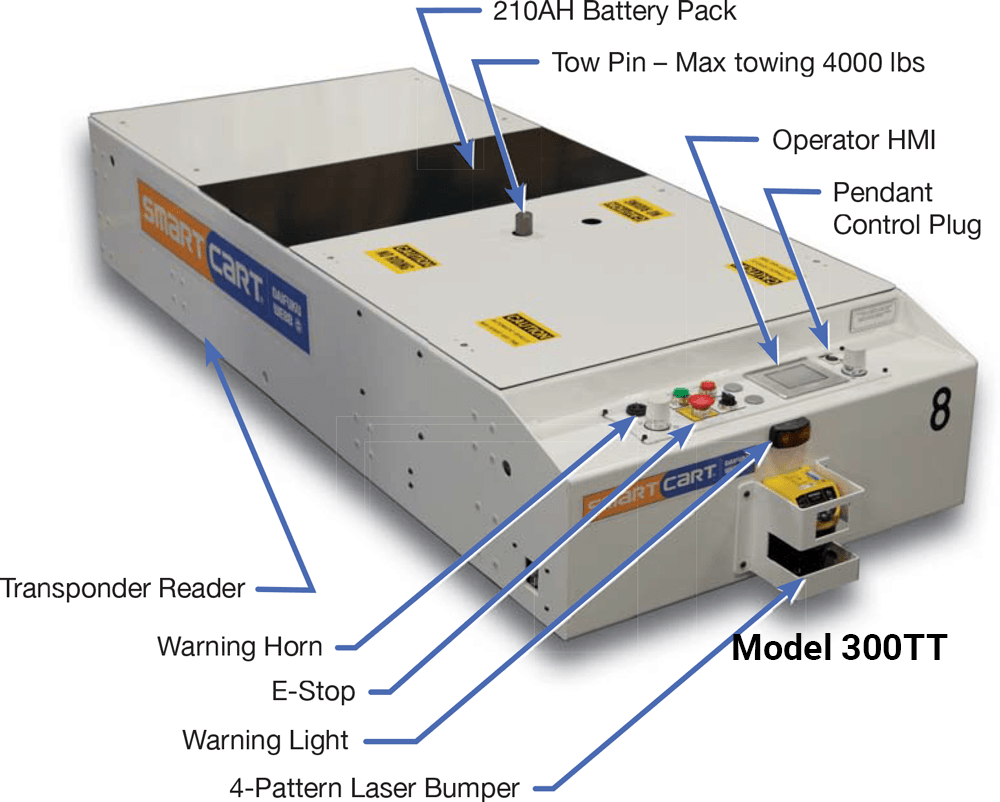

- M300-TT

- M100-ST

Read more about SmartCart Applications:

Description

Automated Guided Vehicle (AGV) tuggers are a specialized category of AGVs designed to transport and tow materials, carts, or other loads within a facility. These vehicles are used in a wide range of industries, including manufacturing, distribution, and warehousing, to automate the movement of heavy loads, streamline material handling processes, and reduce the need for manual labor or forklifts.

Here are some key features and characteristics of AGV tuggers:

- Towing Capabilities: AGV tuggers tow one or more carts or trailers loaded with materials. The TT models are designed to move under racks and trailers to tow them from underneath- reducing the overall footprint. They can move loads ranging from raw materials to finished products, and the towing capacity varies depending on the specific model and configuration. Download the brochures above for specific information, but the load max is also in the model’s name.

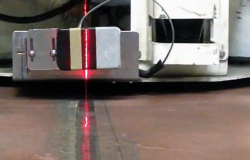

- Guidance Systems: AGV tuggers rely on magnetic paths or can use Natural Feature Navigation to follow paths, markers, or predefined routes within the facility.

- Autonomous Operation: AGV tuggers operate autonomously, without the need for human intervention. They can follow predetermined paths or adapt to changing environments using obstacle detection and avoidance capabilities, ensuring safe and efficient material transport.

- Flexibility: AGV tuggers offer flexibility in terms of load configurations to accommodate various load sizes and shapes.

- Integration: They can be seamlessly integrated into existing manufacturing or warehousing systems. This integration often involves communication with the facility’s Warehouse Management System (WMS) or Manufacturing Execution System (MES) to coordinate material movements and optimize workflow.

- Safety Features: AGV tuggers are equipped with advanced safety features, including sensors and emergency stop mechanisms to prevent collisions and ensure the safety of both the equipment and personnel in their vicinity.

- Efficiency: These AGVs are known for their efficiency in material handling. They operate 24/7, pulling over to charging stations as needed. This offers consistent and precise transportation at all hours.

- Cost Savings: By reducing the reliance on manual labor and the potential for errors or accidents, AGV tuggers can result in cost savings and improved operational efficiency over time.

AGV tuggers are a crucial component of modern automated material handling systems, offering a versatile and reliable solution for efficiently moving materials and improving logistics processes within a wide range of industries.