The SmartCart Automatic Guided Cart (AGC) from Daifuku is an industry leading product for cost-effective material delivery and take-away for your robotic palletizing/unitizing system, or other robotic work cells. SmartCart AGCs are quickly becoming a material handling necessity in developing efficiency and perfecting timing in automation processes.

SmartCart AGCs are also the leading form of low to medium volume moving line assembly application, globally.

Are you familiar with the SmartCart AGC product line? Here are some of the things adding an AGC can do for you:

- Eliminate repetitive stress injuries

- Fully automate routine delivery tasks

- Make sure material is delivered on time, every time

- Work multiple shifts – with no shift premium and 100% attendance

Some of the numerous applications where SmartCart AGCs are currently reducing costs and improving material delivery and assembly methods include:

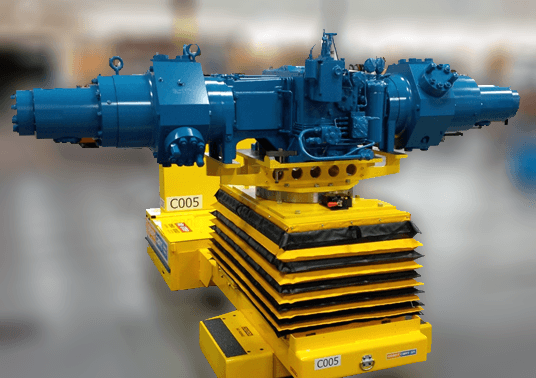

- SmartCart AGV moving large products to multiple stations for assembly.

- Automotive instrument panels, door, and seat assembly

- Appliance assembly

- Assembly of a compressor product for a leading company in the oil and gas industry (installed and presented by Motion Controls Robotics shown in adjacent photo) Watch Video on YouTube

- Large sheet good handling

- Recreational vehicle and personal watercraft assembly

- Motorcycle assembly

- Work in process (WIP) transportation from kitting areas to any assembly line

As a value-added reseller of SmartCarts, MCRI recently learned about some great add-ons to enhance your current AGCs or to think about adding when developing a new automation process.

AGC Trailers for SmartCarts

Topper Industrial has several four-wheel steer trailers designed specifically for SmartCart AGCs. These trailers follow the path of the AGC very closely, and can be modified to suit very custom load requirements and special handling at the AGC pick and drop areas. One trick with these trailers is applying Rhino Lining to the trailer decks to reduce noise and improve friction on the deck surface.

Ramps

AGCs can now be used on inclines (ramps). When developing a system, complete information about the ramp grade(s) and length(s), and the AGC duty cycle and load weight will be needed to certify use of an AGC in any ramp application.

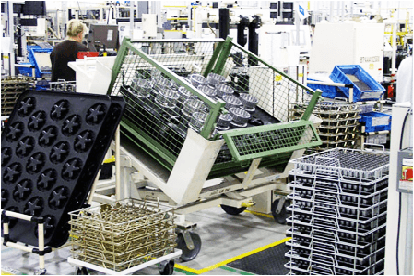

SmartCart Delivery of Parts to an Assembly Area

Tube and joint style frames like those from Trilogiq USA are growing in popularity in automotive assembly plant and Tier 1 component assembly plants, as well as other general manufacturing where kitted WIP material needs to be routinely delivered to an assembly area.

CSA Approval

There is also exciting news for our Canadian customers as the SmartCart core products now have CSA approval.

Wireless Upgrade

The SmartCart AGC product line has benefitted for many years from WiFi wireless communications technology; the SAM upper-level control computer communicates continuously for AGC dispatching and traffic controls using wireless communications.

Now wireless communications are being used for remote Input/Output (I/O) communications as well. Webb introduced Banner’s SureCross wireless I/O backbone for easy setup and elimination of hard wiring to remote locations for input from sensors and control of various devices.

Please contact us if you have any operations where operators are currently moving components or finished assemblies with pallet jacks, pushcarts, fork trucks, tow motors, or by hand. We can;

- reduce your costs

- free up valuable labor for more demanding work

- improve material delivery reliability along with your bottom line