Recent News from Motion Controls Robotics

Motion Controls Robotics’ Robotic Roll Handling Systems

Motion Controls Robotics, Inc (MCRI) is exhibiting at both the North and South Converters Expos in 2024. They will be turning heads with the in-depth experience and flexible system design…

MCRI Employee Announcements

Strategic Expansion: Motion Controls Robotics Strengthens Sales Team for Continued Growth and Customer Success! Fremont, Ohio — Motion Controls Robotics (MCRI), leading provider in robotics and automation solutions, is pleased…

MCRI to Host Maximize – Open House Event

FREMONT, Ohio, July 25, 2023 - Motion Controls Robotics, a leading provider of robot system integration solutions, is thrilled to announce its upcoming open house event, "Maximize." This event will…

MCRI 2023 Expansion Project

Motion Controls Robotics, based in Fremont, Ohio, provides fully integrated robotic systems to a variety of industries, including food and beverage, consumer packaged goods and manufacturing. These industries are integrating…

MCRI Partners with MiR for AMR Integration

Motion Controls Robotics, Inc (MCRI) joins Mobile Industrial Robots’ (MiR) Certified System Integrator (CSI) program for AMR integration Motion Controls Robotics forms partnership with top Autonomous Mobile Robot manufacturer, MiR,…

Bring Robotic Automation to Warehouse Operations and E-Comm Fulfillment

Motion Controls Robotics and Plus One Robotics Partner to Bring Robotic Automation to Warehouse Operations and E-Comm Fulfillment Partnership enables businesses to quickly install robust, scalable robot associates to handle…

Industrial Software Department Helps Customers Connect Production and Front Office

Powerful Data Gathering Transforms How Real-time Production Information is Used by Decision Makers Motion Controls Robotics to Launch their New Industrial Software Department to Help Customers Connect Production and Front…

Lang and Ellenberger Join the FANUC President’s Circle

Motion Controls Robotics' Scott Lang and Tim Ellenberger Honored with Prestigious FANUC President’s Circle of Achievement Award at the 2020 FANUC ASI Conference Motion Controls Robotics attended FANUC’s 2020 ASI…

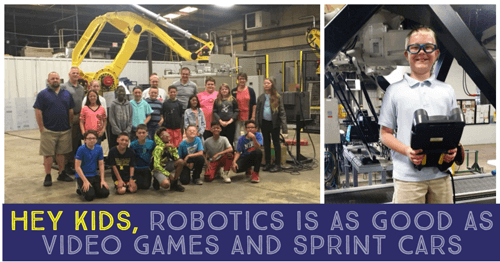

Hey Kids, Robotics is as Good as Video Games and Sprint Cars

While the industrial robotics industry has been around since the 1950s, and hit its stride in the 1980s, pursuing an education in industrial robotics is still not in the front…

TUV Rheinland Functional Safety Certificate

Lead Controls Engineer at Motion Controls Robotics becomes one of the 14,000 engineers worldwide to receive a certificate in Functional Safety from TÜV Rheinland. The TÜV Rheinland Functional Safety Training…