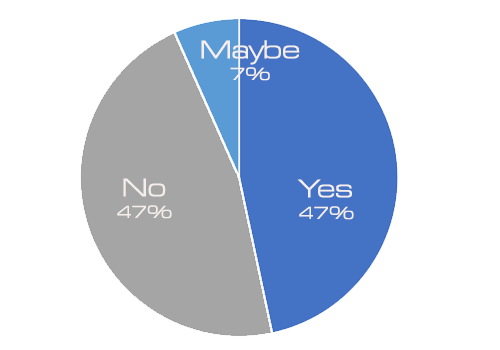

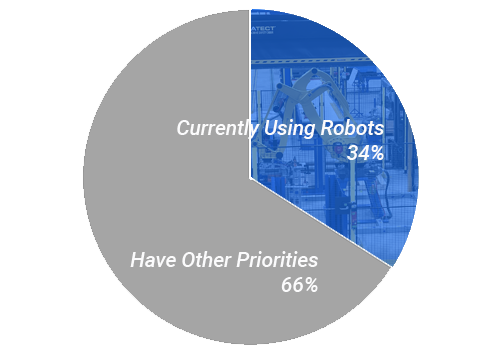

We recently conducted a survey across 200 manufacturing facilities in the United States to delve into the perspectives on robotic benefits.

One of the questions was, “Which Statement better defines your facility?”

- Automation is on our radar, but we have other projects that are taking time and budget.

- Our plant is committed to automation, we have projects under consideration, and budget for new projects.

When asked about their facility’s stance on automation, the majority (66%) expressed that while it’s on their radar, other ongoing projects are consuming their time and budget. We understand the challenges you face, and this article aims to shed light on how embracing automation can substantially enhance various aspects of your manufacturing environment.

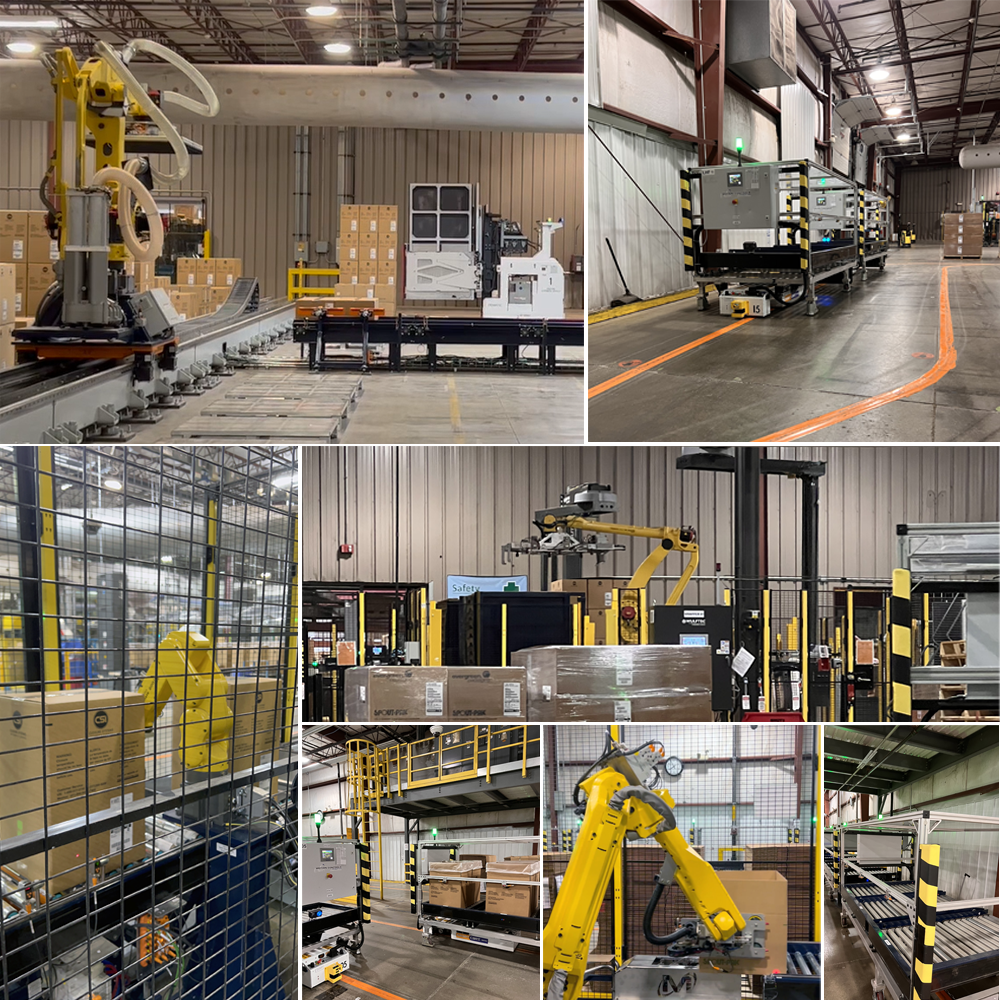

Robotic Benefits:

Embracing robotics can yield significant advantages for your facility, including:

Improved Throughput

By enhancing process efficiency through robotic automation, you can boost throughput without the need for expanding floorspace.

Better Safety

Improve employee safety by eliminating repetitive motion, heavy lifting and other hazardous environment dangers.

Improved Quality

Incorporating robotics into production processes enhances overall manufacturing accuracy using automated and reliable operations.

Process Efficiency

Robotic automation adds speed and reliability to your application and expands manufacturing time by allowing for 24/7 operation.

Sustainability

Implementing robotic systems streamlines operations, optimizing resource utilization, and reducing environmental impact through efficient and precise automation.

Labor Reliability

Moving employees to more rewarding and value added positions, you will see less employee turnover.

The above improvements might not only address current challenges but also contribute to solving other issues you may be grappling with.

Addressing Concerns about Industrial Robotics:

We have existing projects and priorities before we start with automation.

✅ 🤖 Robotics can complement and enhance existing projects, speeding up processes, reducing errors, and freeing up human resources for more complex tasks. You might find that the benefits of industrial robots solves the concerns you are trying to address and give you access to more employees to help with other issues.

Industrial robotics can be a significant capital investment and I am not sure of the ROI.

✅ 🤖 Most automation projects boast a less than three-year ROI, leading to long-term cost savings, increased efficiency, reduced labor costs, and enhanced flexibility. MCRI has systems with a proven track record of over 15 years.

We lack the expertise to integrate and maintain robotic systems.

✅ 🤖 MCRI supports you throughout the entire journey, recommending the formation of an automation team with a designated leader. Our user-friendly robotic systems require minimal technical knowledge, and we provide onsite training along with various training programs.

We don’t want employees to fear job losses due to the introduction of robots.

✅ 🤖 Robotics offers collaboration opportunities, allowing humans and robots to work together. This shift creates new, higher-skilled jobs in maintenance, programming, and supervision.

Did you know, according to McKinsey, that manufacturing and logistics facilities plan to invest 25% of their capital in industrial automation over the next five years? This statistic underscores a broader industry trend, emphasizing the strategic importance of embracing automation for sustained growth and competitiveness.

On your path to understanding robotic benefits:

- Real world example by watching automation videos – To start, subscribe to MCRI’s YouTube Channel

- Then look for testimonials from facilities that have already taken that first step – Read our testimonials

- Next, read case studies – See MCRI Case Studies for a variety of Systems

- Finally, Review industry statistics – McKinsey’s Comprehensive Overall Study

You will start to see how industrial robotics is a strategic investment for future competitiveness and a crucial element in your facility’s evolution.

Other Survey Questions about Robotic Benefits:

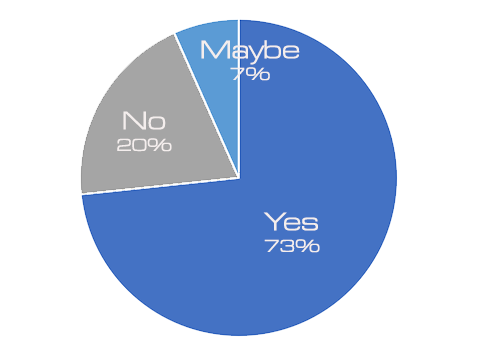

Could adding robotics & automation in your facility reduce safety concerns – such as fork truck traffic & operator ergonomics?

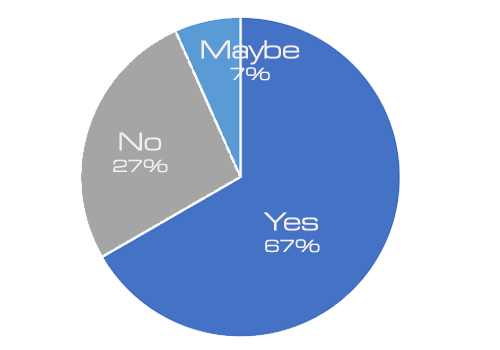

Is your facility interested in learning more about the capabilities and limitations of collaborative robots?

Does your company have an automation team/group that evaluates process updates?

Not only is this a goal for a lot of facilities, but it is a recommendation we give to all our customers. MCRI will be discussing in follow-up posts how companies can develop and educate automation teams. So check back to learn more.