Video example of improved robot programming

Motion Controls Robotics recently received this question, “Outside of the teach pendant, how are robotic movements typically programmed?“

This article explores the essential insights into robot programming as we explain the pivotal role of experienced programmers. In the world of robotics, the old adage ‘you don’t know what you don’t know’ rings particularly true. Join us as we explore the critical nuances and expertise required in this dynamic field.

It is a typical sight on the MCRI design floor to see a Programmer positioning a robot in relation to other items in the system with a teach pendant. The teach pendant can be used to manually program points and move the robot almost like a remote control. Teaching a robot means programming precise positions (movement) and procedures. While this manual controller (teach pendant) is easy to spot and commonly used, there are a variety of other programming techniques that can also be used to program the robot’s positions.

Robot Programming

- CAD to Path – operator gives a robot the ability to perform certain functions by defining part geometry in CAD and downloading it to the robot controller – to paint a car, weld a seam, or grind the edge of a product for example.

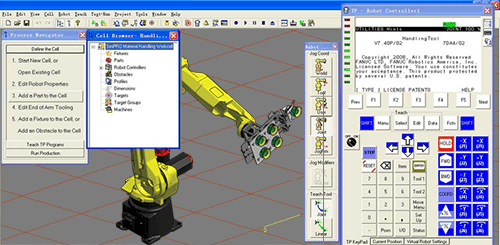

- FANUC’s ROBOGUIDE – PC software designed to simulate the physical robot and the equipment it will interface with. Programming can occur on the Virtual Teach Pendant available through the ROBOGUIDE software. Actual real world robot programs can be loaded into ROBOGUIDE and the programmer can make program changes and additions using the software and then load these files into the real world robot. Programs created or modified in ROBOGUIDE can be ran and tested in the virtual world using the software.

- Some robots can be manually guided through motions, with input buttons used to record or mark start and finish points of moves, and to identify where other functions need to be performed such as gripping or releasing a part. FANUC’s new collaborative CR-35 robot allows programming through manual manipulation at the end of arm tool.

- Robots that are already programmed to handle specific parts and perform specific functions can be parametrically told to handle similar parts with different dimensions, or case pack or palletize in a different pattern, or insert screws into a different shaped product. The integrator needs to create the parametric programming up front and load it into the robot’s controller, then provide a means for an operator to add parts and new part parameters (usually through an HMI operator screen).

- Sometimes it is just a skilled, experienced robot programmer that makes a big difference. Knowing robot motion and spotting inefficiencies can change your rate and improve your overall system. In the video example at the top of the page, the robot cycle was taking 57 seconds per part. Our programmer noticed the issue and was able to get the cycle down to 51 seconds. That is a savings of 6 seconds. Basically, that means 60 extra parts every 8-hour shift. That is an 11% increase in press utilization just from having a skilled programmer step in and make some changes.

Motion Controls Robotics is happy to answer any questions about robotics. Follow us on:

to read all our new Tech Talk articles.