Understanding Vacuum Plenums as a Material Handling Resource

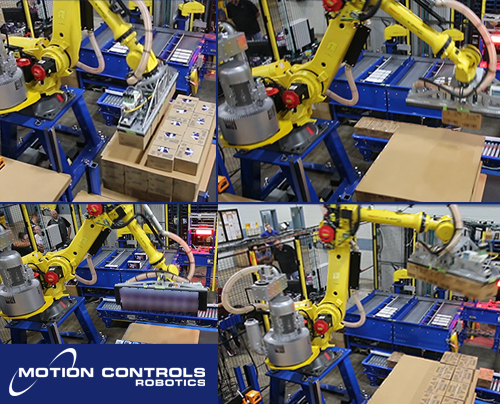

Vacuum plenums as end of arm tools are becoming a more and more common solution seen in robotic material handling applications. This is because vacuum plenum tools can provide flexibility and offer some advantages over other traditional end effector tooling choices. However, it’s important to understand what applications this technology is suited for, and which it is not.

Benefits of Selecting Vacuum Plenums for your Palletizing System

The largest benefit to vacuum plenum tools is that they can provide many points of vacuum in a condensed space. “Vacuum plenum” refers to a centralized chamber for generating vacuum. These chambers can have many outlets to allow for a dense vacuum array. These “outlets” can be traditional vacuum cups, or they can be round openings in a non-porous foam pad.

Other benefits:

- Condenses tooling profile

- Can reduce number of airlines required compared to a decentralized system

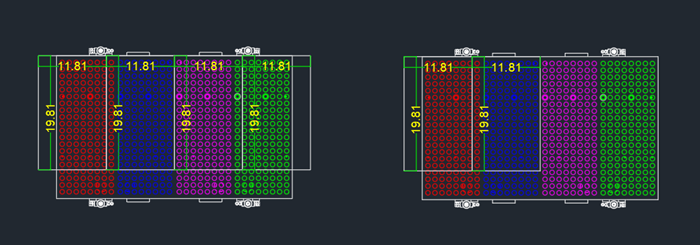

- Allows for a wide array of pick patterns

- Increased vacuum density can allow for more points of vacuum in contact with the picked object

- Foam tooling can allow for a good seal on irregularly shaped objects

- Can utilize “zoning” for more specific pick and place applications

See Several Vacuum Plenums Picking & Palletizing Applications

How Vacuum Plenums Work

As mentioned above, vacuum plenums are a form of centralized vacuum. Creating vacuum in a centralized chamber can reduce the profile of a tool, as it no longer requires vacuum generation for each outlet. However, the drawback is that if air can flow through the outlets, like in the case of a bad seal or pick, then the amount of vacuum being generated is depleted. At best this can result in less picking force, at worst it can result in a complete loss of vacuum; either result can lead to dropped product. To combat this drawback, most vacuum plenums implement a form of mitigation. The two most common forms are check balls, and flow restrictors.

Check Balls

Check balls are essentially ball bearing balls that are placed in cylindrical channels between the plenum vacuum chamber and the outlet (whether that be an opening in a foam pad, or a vacuum cup). When vacuum is created in the plenum, the balls are drawn in that direction. If a good seal was made at the outlet, then a small vacuum force is created between the ball and the outlet; the function is very similar to that of a plunger in a syringe. This translates into a force attempting to hold the object or product to the tool.

- Check balls prevent additional airflow by sealing the cylindrical chamber connecting the plenum to the outlet – this is good for preventing loss of vacuum.

- Check balls are not good for applications where the picked object or product is porous. In these cases, the trapped air between the check ball and the outlet can leak through the material being picked, removing the vacuum.

- If a good seal is not made at the outlet, or if the seal is temporarily broken, then the ball will “check” and prevent further vacuum pull.

- Good for applications handling non-porous materials (i.e., metal cans, glass, plastics, etc.)

Flow Restrictors

Flow restrictors work to reduce the amount of air that can be pulled through an outlet. Reducing low helps to prevent losing vacuum at a greater rate than it can be generated. This allows for picking with less than perfect seals between the outlet and the object being picked.

- Flow restrictors require more vacuum generation but allow for more porous materials to be picked, as the continuous flow can help to overcome some material porosity.

- Flow restrictors have the potential to regrip if the seal between the outlet and the object being picked is temporarily lost, unlike with check balls where the vacuum generation is completely halted after the initial pick.

- Good for applications handling non-porous and semi-porous materials (Can be used in some cardboard box/case application)

Best Applications for Vacuum Plenums

Plenum tools can be used for a variety of products; allowing for a variety of pick patterns and unique shapes, plenums are a very flexible option.

Perfect Applications for a Vacuum Plenum

- Picking non-porous material like metal, plastic, or glass.

- Picking dense unit layers of non-porous materials

- (Foam Pad) Picking uniquely shaped non-porous materials that are difficult to seal with vacuum cups.

Great Applications for a Vacuum Plenum

- Picking sturdy semi-porous materials like dense cardboard, or cardstock

- Picking dense unit layers of semi-porous materials

- Picking unit layers with inconsistent patterns of semi-porous materials

Bad Applications for a Vacuum Plenum

- Picking flimsy or porous materials like thin cardboard

- Picking any open top liquids

- Primary food handling applications

- Picking dense product with limited pick surface area

- Picking poorly sealed cases (where tape is transferable, or case integrity could be in question)

Motion Controls Robotic soften selects vacuum plenums for their centralized palletizing cells where flexible palletizing options are a must to handle varied product sizes and shapes with one robot.

MCRI builds full robot systems – we do not sell the tooling alone our goal is to help our customer be informed of options available for the end results. We use a variety of vendors to select the vacuum plenum that works best for the system design.

Contact MCRI if you are looking to add robotic palletizing to your end of line.