Customer Challenges

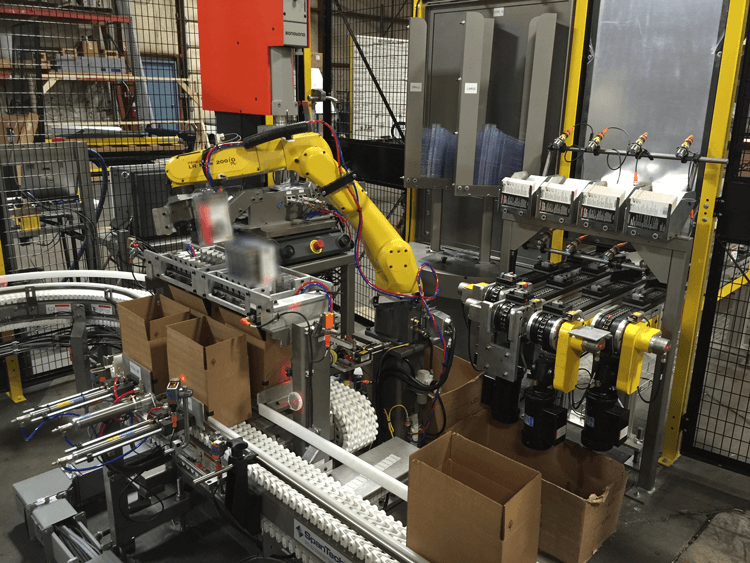

This end of line robotic packaging and case packing system is a perfect example of the type of repetitive motion activities robots were designed to do. This customer needed the robot cell to accomplish eight tasks in a small work envelope and meet a designated rate.

Robotic Packaging Assembly and Case Packing Steps:

- Erect empty cases

- Present parts from assembly to the packaging area

- Pick a part off of an infeed conveyor

- Pick a cardboard insert and plastic packaging clamshell from filled dispensers

- Place the part and insert into the clamshell packaging

- Move the part through the clamshell welder

- Pack the assembled package into a case

- Tape the finished case closed and send off to a palletizing area

Robotic Packaging and Case Packing System Solution

The varied LR Mate options saved the customer money over having to use two robots in the cell and helped to keep the final design very compact.

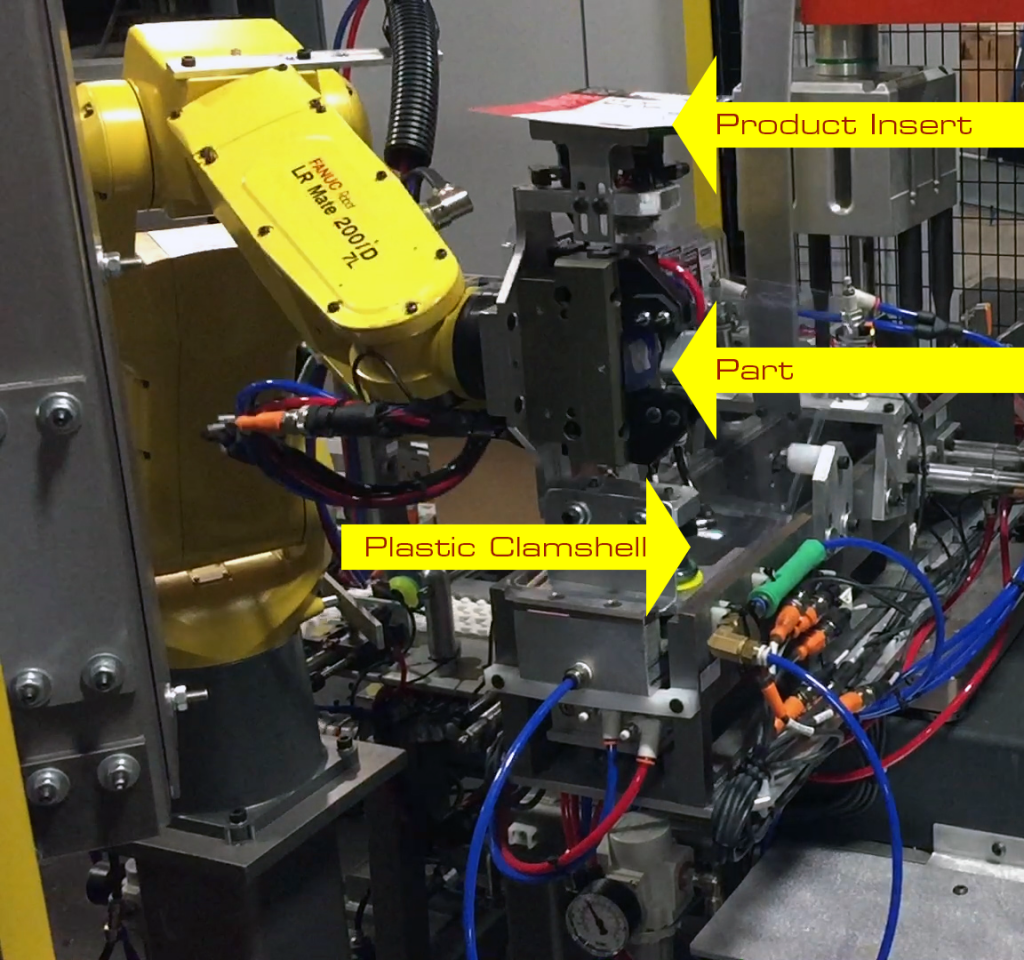

The varied LR Mate options saved the customer money over having to use two robots in the cell and helped to keep the final design very compact.Motion Controls Robotics designed a robot cell that incorporated the customer’s current clamshell welder. The robot picks a part from an infeed conveyor along with a product insert, and then picks the plastic clamshell and carries them to a packaging assembly station in a single robot cycle.

The robot places the clamshell on the welding infeed station, then places the product and insert in the correct order. The clamshell welder seals the packaging and product. While the welder is sealing the clamshell, the robot moves around to place the sealed packaging in the case packing rack. The robot then repeats the cycle.

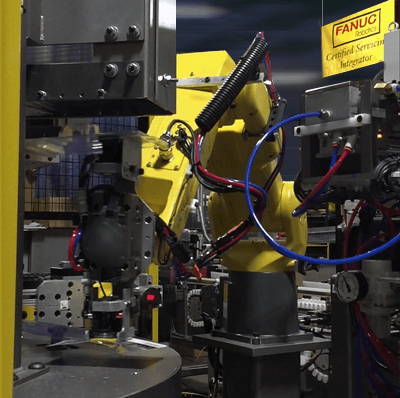

The Robot

The robot selected for this cell is a FANUC LR Mate 200iD 7L. This robot was selected for its speed and longer arm reach. The FANUC LR Mate 200iD 7L is fast at handling small loads (live load plus end of arm tool) of less than 7 kg or 15 pounds. This six axis robot is the long arm version in the LRMate series. The longer arm allows for a greater work envelope extending the reach to 911mm or 36 inches. This reach allows the robot to assemble the three-part shipping package, and then pack the cases.

MCRI used a Combi case erector to build cases, and a Combi taper at the end of the line to seal the case before it is sent on down the line for palletizing and delivery.

If you would like more information about customizing a picking & packing and/or palletizing solution for your product, contact Motion Controls Robotics online or call 419.334.5886 (Fremont, OH).