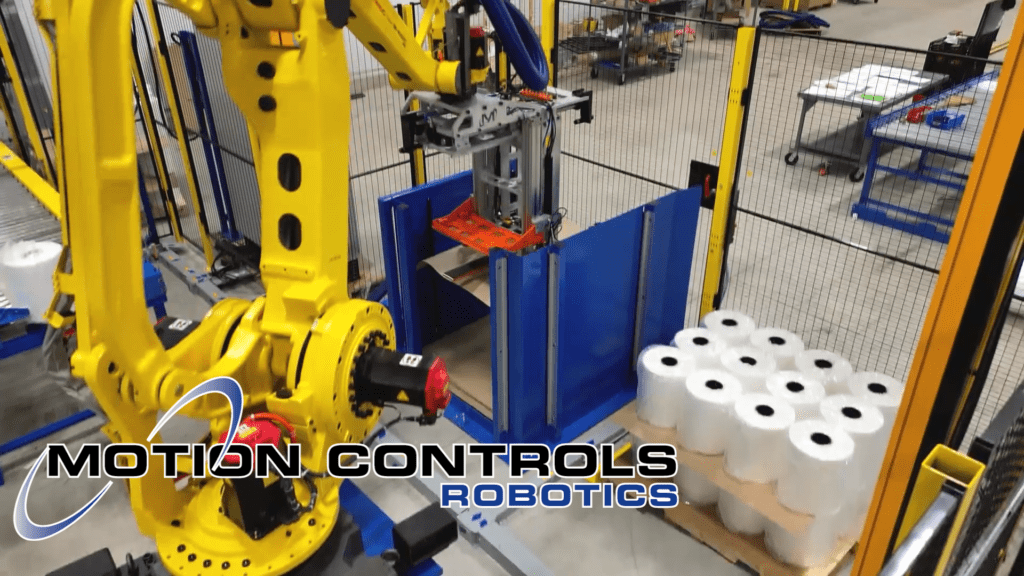

The Dual M-Stack Robotic Palletizing Cell is a cost effective solution designed to streamline the palletizing processes and enhance operational efficiency. These systems can be easily reconfigured to accommodate different product sizes, shapes, and stacking patterns. This palletizing system was designed and built as a solution for handling a variety of rolls, but the compact, symmetric cell could be used to palletize cases, bags, cans, etc.

With two palletizing locations, the Dual M-Stack is a palletizing machine that ensures maximum efficiency in material handling tasks.

Case Study Customer Results

- Solved problem of having employees lift heavy rolls

- Tooling option allows for palletizing wrapped or unwrapped rolls and with or without cores in the same cell

- Compact cell fit the 400 SqFt available

- The system met the rate needed for handling rolls

![]()

Customer’s Challenge

Implementing a robotic roll handling solution like the Dual M-Stack Robotic Palletizer solved numerous issues including:

- The customer had a variety of rolls that went from 20 pounds to 175 pounds.

- Employees were repetitively lifting heavy rolls.

- Needed to improve handling quality of rolls

- Needed to optimize operations to reduced downtime and increased productivity.

- The available floor space was limited, necessitating an efficient and compact palletizing solution.

- Limited budget for the project

![]()

Solution – Dual M-Stack Roll Palletizer

We were able to deign a system with dual palletizing locations using a popular material handling robot to do all the heavy lifting. The efficient design allowed for continuous operation without having to automate moving pallets into and out of the cell. The flexibility of the system extended to its ability to handle a wide range of roll sizes, weights, and configurations. The EoAT could pick a variety of rolls. Whether rolls are in bags or individually wrapped, with or without core plugs, the Dual M-Stack Robotic Palletizer delivers consistent performance and precision.

See how we accomplished all this by watching the system in action.

System Video -The Dual M-Stack Roll Palletizer End of Line Solution

![]()

Sequence of Operations:

- Pallet is added by an operator to both sides of the system.

- An upstream roll upender orients rolls from core horizontal to core vertical before conveying them into the robot cell.

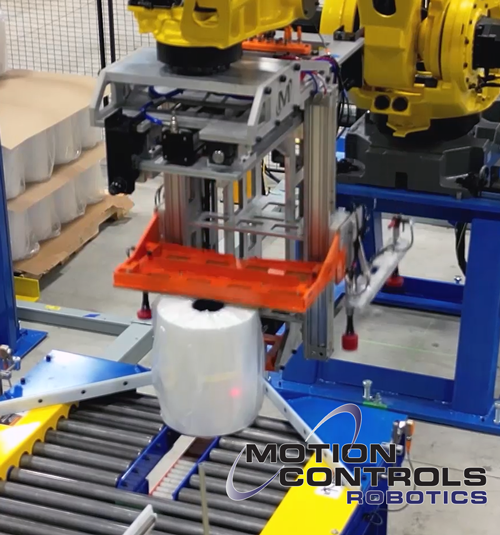

- The robot picks a tier sheet with the vacuum cups located on the EoAT and places the sheet on the empty pallet.

- The robot uses the clamp EoAT to pick rolls and place them on the pallet until the layer is complete.

- The robot places a new tier sheet on each full layer and continues to palletize the rolls until the stack is complete.

- Once the final layer is complete, an integrated safety door partitions the area, allowing the robot to move to the opposite side of the cell to begin building another pallet. This safety feature enables continuous stacking of rolls while ensuring operator safety.

- Meanwhile the FANUC M-410 starts palletizing on the second side of the cell- repeating the process.

- New roll sizes and instructions can be updated at the system’s HMI.

Robot & EoAT

The system incorporates a Fanuc M-410 palletizing robot capable of handling up to a 400-pound total payload. It utilizes a custom-designed clamp tool equipped with vacuum cups for precise picking of tier sheets.

Models |

Payload |

Reach |

Download Spec Sheet |

| Floor Mounted | |||

| M-410iC 185H | 185 kg | 3140 mm | M-410iC-185.pdf |

✓ Safety Features

Motion Controls Robotics follows the ANSI/RIA R15.08 for robotic Safety Standard designed to ensure employees and robots work safely together. We take full advantage of new safety technologies and innovations as they become available.

Safety is a critical aspect of robotic palletizing. To prevent accidents and injuries, these systems are equipped with safety features such as emergency stop buttons, safety scanners, and protective barriers.

Main Safety Features

- This system is complete with safety fencing and needed safety sensors.

- Light curtains along with requested access equipment prevents operators from entering the robot cells while there is movement.

- This system has an integrated safety partition from Dynatect Manufacturing to allow an operator to remove full pallets from the system while the robot continues to palletize in a second location.

Customer Results – Dual M-Stack

In conclusion, the implementation of the Dual M-Stack Robotic Palletizing Cell has demonstrated advantages for our customer in solving roll handling challenges efficiently and effectively. By replacing manual roll palletizing with a streamlined automated solution, our customer successfully eliminated the risk of employee injury from lifting heavy rolls, improved roll quality, and optimized operational productivity.

The system’s adaptability to handle various roll sizes, weights, and configurations, along with its compact design fitting seamlessly within the limited available floor space, underscores its versatility and practicality. Moreover, with its dual palletizing locations and continuous operation capabilities, the Dual M-Stack Robotic Palletizing Cell ensures maximum efficiency in material handling tasks, meeting the customer’s throughput requirements while maintaining stringent safety standards.

The Dual M-Stack Robotic Palletizer offers unparalleled efficiency, precision, and safety in material handling processes. By partnering with Motion Controls Robotics, your facility can optimize operations, boost productivity, and achieve new levels of success.

Get a Palletizing Machine

Overall, robotic palletizing is a versatile and adaptable solution for automating the labor-intensive task of palletizing products or materials. It enhances productivity, reduces errors, and offers a competitive advantage to facilities in logistics and manufacturing.

Ready to revolutionize your roll handling processes? Contact Motion Controls Robotics today to discuss your roll handling project and explore how the Dual M-Stack Robotic Palletizer can transform your operations.