Why Choose a FANUC Authorized System Integrator (ASI) for Your Automation Needs?

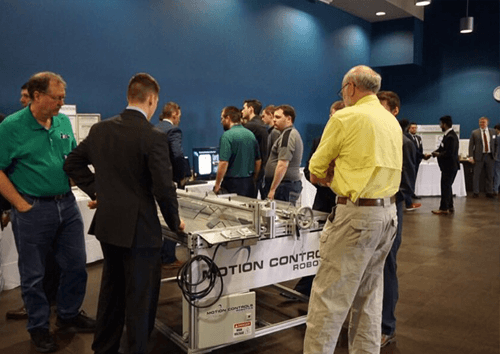

Motion Controls Robotics has been a proud member of the FANUC America Authorized System Integrator Network since 1999. Being a FANUC Level 4, Certified Servicing Integrator means we are one of the few Authorized Integrators to provide innovative robotic solutions from concept to installation and the 24/7 service and support for complete customer confidence.

Partnering with a FANUC ASI gives you access to highly trained engineers, techs, and programmers equipped with the latest FANUC technologies and support. This collaboration leads to customized, efficient, and reliable automation solutions that enhance productivity and provide a solid return on investment.

Where Your Automation Excellence Comes to Life

A Full Spectrum of

Robotic Integration Services

Our facility’s cutting-edge equipment and capabilities enable us to provide comprehensive robotic design, construction, integration, servicing, and training support to each and every one of our customers.

- FANUC Level 4 Certified Servicing Integrator

- Project Management

- In-House Electrical and Mechanical Engineering

- Robotic simulation using FANUC SimPRO™

- Process Simulation

- Turnkey Systems Integration

- Full-Service CNC Machine Shop

- UL Certified Panel Build

- Custom, Flexible End-of-Arm Tooling

- Fabrication, Paint, and Assembly

- Robot, PLC and HMI Programming

- Service and Preventive Maintenance

- In-House or On-Site Robotic Training

- Discounted Spare Parts and Service

- Fast, Friendly Customer Service and 24/7 Support

State-of-the-Art Facility Features for Precision Work

Our design and testing facility includes a fully equipped machine shop and fabrication area and a 2,000 square foot flow-through paint booth for highly precise robotic systems, customized components, and high-quality finishes. Here, each automation solution we build is tailored to our customer’s unique requirements and industry standards and coated with custom finishes to protect from wear and maximize operational lifetime.

With two truck wells, three grade level, 16-foot doors, and the equipment to load and unload equipment of all shapes and sizes from flatbed and drive-in trailers, we’re prepared to move our materials and products anywhere they need to go.

Comprehensive Training with Demonstration Cells

When we build a new robotic work cell for your production or warehousing facility, your workers need training—and they can get their operator training on-site or visit our Fremont facility for hands-on experience with operation and troubleshooting.

Decades of Trusted Industry Connections

Our design and testing facility includes a fully equipped machine shop and fabrication area and a 2,000 square foot flow-through paint booth for highly precise robotic systems, customized components, and high-quality finishes. Here, each automation solution we build is tailored to our customer’s unique requirements and industry standards and coated with custom finishes to protect from wear and maximize operational lifetime.

With two truck wells, three grade level, 16-foot doors, and the equipment to load and unload equipment of all shapes and sizes from flatbed and drive-in trailers, we’re prepared to move our materials and products anywhere they need to go.

We’re All-In on Building a Complete Robotic Solution

With our major production facility’s extensive, cutting-edge technical capabilities, our vast industrial automation expertise, and the level of friendly customer service you can only find in the Midwest, MCRI is ready to bring your manufacturing and product distribution capabilities into the future.