Customer Challenges – Part Stacking – Multiple Lengths and Widths

“ We were looking for highly capable company to partner with for a challenging part stacking automation project. We needed a company that could successfully take the lead and manage the project thru concept, design, procurement and launch. MCRI did a tremendous job in all phases of the project and their professionalism and attention to detail was evident throughout the project.“ ~Sauder Automation Specialist

Sauder, a top ready-to-assemble furniture company out of Archibold, Ohio, came to Motion Controls Robotics to find a robotic solution for a part stacking operation. Their goal for automating was to improve the overall efficiency, quality, and safety of the process. Using a robot to stack parts means they can:

- Reduce headcount in a tight labor market

- Reduce the complexity of machine scheduling around tight labor availability

- Increase throughput – They currently are running three shifts of product and would like to increase throughput. Robotic automation is an efficient way to accomplish this.

- Focus on safety and quality – Adding a robot to stack the basic parts as they leave the bander allows employees to focus on other specialty part stacking and quality control. It also decreases the operators’ risk of repetitive motion injuries.

- Improve overall stack quality

![]()

Process Sequence – Part Stacking

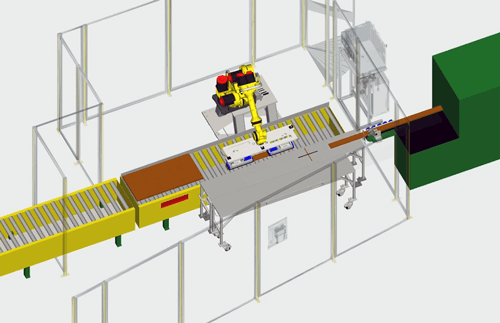

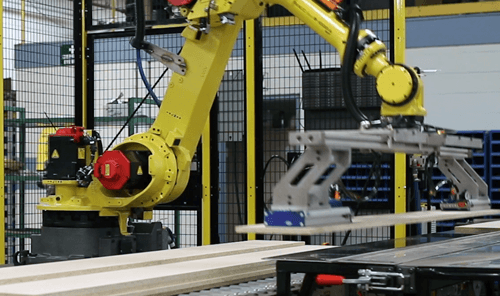

The product being stacked is planks of wood that have just left a bander. The banding connects the planks but is perforated at both ends of the boards. These planks are stacked based on part size. The company had five different stack patterns for the different size lengths and widths of product. Motion Controls Robotics selected the FANUC R-1000iA/80F as the best robot to integrate to accomplish the tasks at the rate required. The robot cell setup allows for up to 1,200 boards to be stacked in an hour. This meets the company’s goal for increased throughput.

Sequence of Operations for Part Stacking

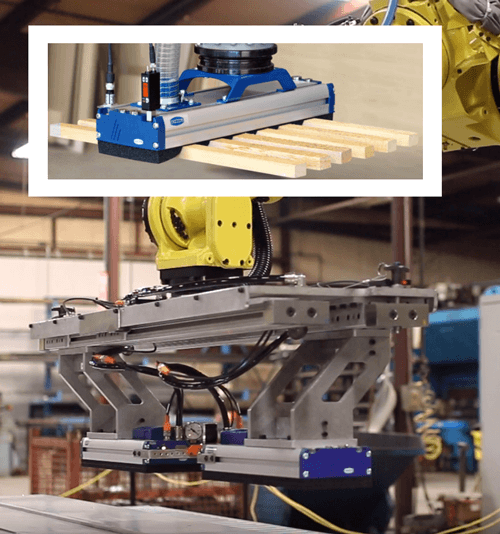

- At the beginning of the production run, an operator manually sets the proper end of arm tool width based on the product size. This setting could be done automatically, but for cost reasons and the infrequent need to make changes, the customer elected to make it a manual operation.

- Next product exits the bander and a sensor locates the leading edge of the board. Then, through the use of FANUC Line Tracking software, the robot determines the center of the plank for a proper pick position.

- The robot breaks the perforated banding that connects the boards as the robot picks up the board.

- Lastly, the robot moves the board to the stacking conveyor and places it on the stack according to the program.

- This process repeats until the stack is complete, and the stacking conveyor moves the full stack out of the area.

- During the process, the robot places any parts with quality issues in the reject cart.

Video shows Part Stacking of different length and width of boards – starting with a 3D simulation of the process and moving through to the actual robot part stacking system

Robot and End of Arm Tooling

Robot selection

The robot integrated for this application is a FANUC R-1000iA/80F Robot with the R-30iB Plus controller. This six-axis robot uses HandlingTool software to move and stack product using the most efficient movements.

Models |

Payload |

Reach |

Download Spec Sheet |

| FANUC R-1000iA/80F | 80 kg/176 lbs. | 2230 mm/88 in | R-1000iA_80F.pdf |

Other uses for the FANUC R-1000 Robot

- Palletizing

- Load/unload operations

- Material handling

The end of arm tooling developed for stacking boards uses two Schmalz Vacuum grippers designed to pick wood products. The End of Arm Tooling is manually adjusted based on the dimensions of the wood.

✓ Safety Features

Motion Controls Robotics follows the ANSI R15.06 Safety Standard designed to ensure employees and robots work safely together. We take full advantage of new safety technologies and innovations as they become available. This system is complete with safety fencing and sensors. There are times when the operators need to enter the area to work. Safety sensors ensure the robot will not run until all workers have left the cell.

![]()

Customer Results

As a result of these changes, the new system keeps the process running at a consistent and predictable rate throughout the three shifts.

If you have a similar application that consists of picking and placing product into stacks, contact us to find out how line tracking and sensing can be combined for your best solution.