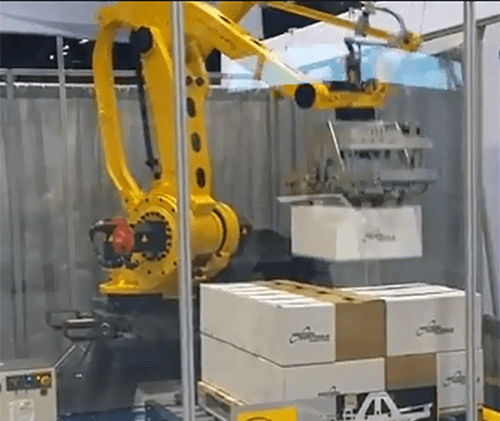

Revolutionize your end-of-line operations with the best in user-friendly, cost-effective palletizing solutions.

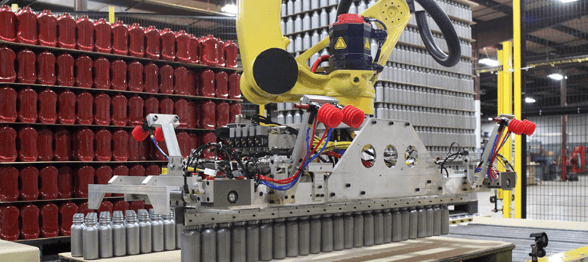

Robot Palletizing Systems

Enhance Your ROI

Robotic palletizers handle high product throughputs and can run 24/7—handling more products, faster, and more consistently than human workers.

Improve Employee Safety

Robot palletizing systems handle tedious picking, packing, and heavy lifting operations—tasks that could otherwise cause repetitive motion injuries in your human employees.

Reduce Operating Costs

Custom pallet robot systems optimize space and efficiency, lower your labor costs, and decrease the risk of damage to your products during end-of-line operations.

Optimize Your Workflow: Download the Packing and Palletizing E-Book

What You’ll Learn in This Packing and Palletizing E-Book:

Case Packing and Palletizing Flexibility

How Robotics can Adapt to your Application

Tips for Integrating Technologies Seamlessly and Effectively

Unlock the potential of robotic automation to streamline your processes and boost your bottom line. Download our e-book now and start your journey towards operational excellence.

Why trust Motion Controls Robotics for palletizing robot solutions?

Since 1995, we’ve combined state-of-the-art robotics expertise with service that is anything but robotic.

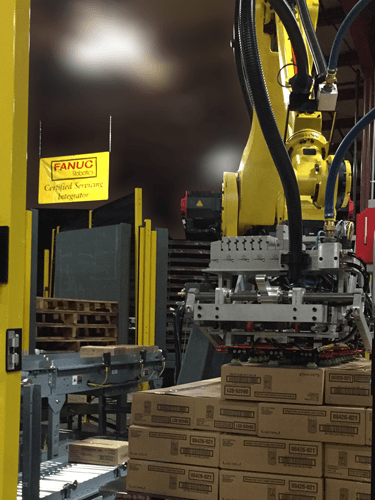

FANUC Level 4, Certified Servicing Integrator

Our robotics integration capabilities are certified by the titans of the industrial automation world. We get the job done quickly, designing, installing, setting up, and certifying our customer’s new systems to minimize downtime and make it as easy as possible to reap the advantages of robotic palletizing.

A Proven Track Record of Automation Excellence

As one of the 10 recipients of the FANUC President’s Circle of Achievement Award, we boast 25+ years of experience on the cutting edge of industrial robotics and commitment to the highest possible standards of quality. Our customers know they can trust our solutions to help them succeed.

Fast, Friendly Customer Service

A customer of Motion Controls Robotics is a customer for life. We put our whole hearts into comprehensive customer service, including round-the-clock technical support, so our customers know they can count on us to keep their systems running smoothly 24/7 with as few hiccups as possible.

See for Yourself What Our Robotic Palletizers Can Do for Your Business

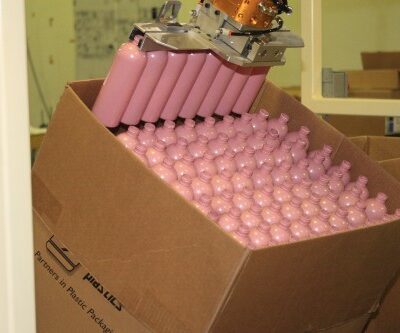

Our Palletizing Robot Solutions Make It Easy to Handle

CASES

PLASTICS

ROLLS

BAGS

CANS

AND MORE!

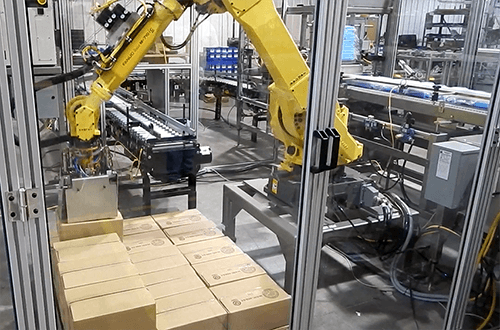

Features of Our Custom Pallet Robot Systems

- Easy and intuitive to program, operate, and make on-the-fly process adjustments

- Capable of handling various stack patterns

- 80,000 hours of mean uptime

- High cycle rates up to 28 strokes per minute

- Decreases repetitive motion injuries from picking, packing, and heavy lifting

- More consistent controls

- Higher throughput with separate infeed conveyors and consistent 24/7 operation

- Flexible tooling to support a wide range of product dimensions

- Interfaces to bar code readers or identification devices

- Centralized data entry and ERP integration

- Reduced risk of packaging damage

- Improved customer order fulfillment accuracy and satisfaction

Request a Quote for Palletizing Robots and Related Systems

Bring a new level of safety and efficiency to your production environment and free your workers from tedious manual labor with pallet robot systems tailor-made to enhance your efficiency, reduce your labor costs, and improve the quality of your products.

Palletizing Robot Systems FAQ

A palletizing robot is an industrial robot designed to automatically stack and arrange products onto pallets—meaning you can get more done faster and without the need for straining or potentially unsafe manual labor.

As the name suggests, a depalletizing robot does the exact opposite of robotic palletizers—instead of stacking products up on pallets, it removes products from pallets and sends them along for further processing or distribution.

Palletizing and depalletizing robots don’t usually work alone—they work as part of an integrated system that includes the robot as well as safety equipment and other related automation components, such as robotic simulation and vision systems, to help it handle palletizing tasks. A palletizing robotic work cell can fit into a space of just a few dozen square feet!

The cost of pallet robot systems varies depending on the complexity of your facility and the capabilities you can require, ranging on the low end from $50,000 to the high end of $150,000. We provide a free downloadable palletizing calculator form to help you figure out how much your robotic palletizing system could cost.

When you trust Motion Controls Robotics with your robotic palletizing solutions, you put your trust in FANUC—the leading supplier of industrial robots throughout the world. Their newest robots run anywhere from 80,000 to 1,000,000 hours between failures. Divide that by the average 2,000 hour automated work shift, and you can expect 10-20 years of reliable service in a three-shift operation!

Just because we’ve installed your system and left your site doesn’t mean our work is done. If your palletizing robot or any other cell components break down or encounter any other problems, we can diagnose its failure and help you get up and running again on-site or through remote service packages.

When you order a custom robotic work cell from us, we make sure you feel confident in using it to its full potential. And yes, that includes as much hands-on training as your team requires, either at our plant in Fremont, OH or at your site. As a Level 4 Certified Servicing Integrator for FANUC Robotics, we’re also certified to provide training classes for any FANUC robot—even ones supplied by our competitors!

Still have more questions about palletizing robots? We’ve got more answers.

Find Out Why Our Customers Keep Coming Back for More

“Motion Controls has been a Robotic Integrator of choice for our company for years. In our facility alone, they have perfectly executed 7 automation projects that have helped us become leaner and more efficient.”

– Windsor Mold Group

“Motion Controls has proven themselves to be a highly intelligent and capable robotic integrator. Their team invested the appropriate research and talent to ensure that our needs were met from all aspects of safety, delivery, and performance.”

– Berry Global

“The reason I prefer to work with MCRI is because of their technical knowledge and customer service. Their entire team takes pride in the work and is dedicated to providing a system or solution the customer wants.”

– Kitchen Consumer Products Company