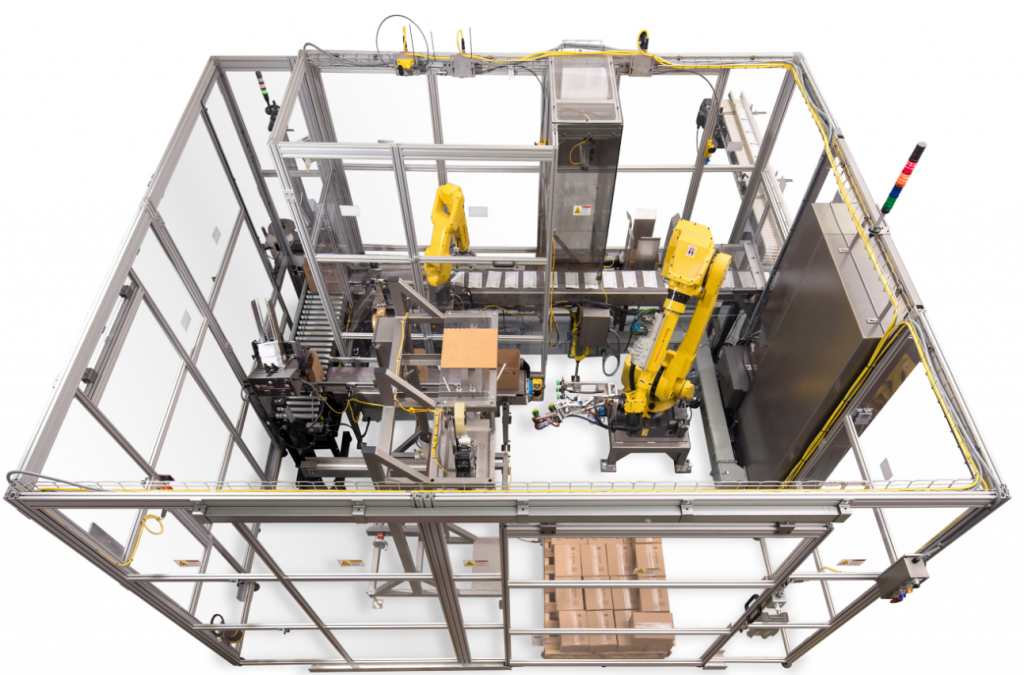

Robotic Pick-Pack-Pal – Case Packing and Palletizing System

Streamline your end-of-line operations with the Robotic Pick-Pack-Pal, designed to handle various product types, weights, and sizes with precision and efficiency. Includes case erecting, packing, sealing, and palletizing capabilities in one complete system.

How Can You Optimize Both Case Packing & Palletizing?

Features and components included in this end of line solution

Case Erecting

The system automatically forms flat boxes into fully erected cases, ready for packing

Case Packing

Products are efficiently placed into the erected cases using robotic arms or other automated mechanisms.

Case Sealing

Once packed, the cases are securely sealed using tape or adhesive for safe transport.

Case Palletizing

The sealed cases are then stacked onto pallets based on programmed pallet patterns.

The PickPakPal Cell utilizes the following stations offering a variety of capabilities:

- Automatic Case Erector

- Product Accumulation

- Case Packing Station

- Product Infeed Conveyor

- Case Sealer (adhesive tape or hot melt glue)

- Case Transfer Conveyor

- Case Palletizing Station

- FANUC M70iC, R1000iC or R2000iC series robots

The Robotic Pick-Pak-Pal includes:

- 6 axis FANUC robot selected for the application- FANUC M710iC robot

- The high speed and compact FANUC R1000 or larger R2000 robot can also be used in jobs where higher weight and/or longer reach are required.

- Fixed robot base anchored to the floor

- Custom, flexible end of arm tool for dual purpose case packing and palletizing

- Integrated FANUC iRVision system/2D Tracking software (optional per application)

- System wiring and controls

- Operator pendant or optional HMI display for recipe management

- Perimeter guarding with safety interlocks on doors

- Programming for Robot, PLC/PMC, HMI and Vision

- On-site Training and Support

- Compliance with all applicable RIA specified safety standards

- Mechanical and Electrical Engineering including layout of cell system, design, and detail

- Options

-

The PickPakPal Cell utilizes the following stations offering a variety of capabilities:

- Automatic Case Erector

- Product Accumulation

- Case Packing Station

- Product Infeed Conveyor

- Case Sealer (adhesive tape or hot melt glue)

- Case Transfer Conveyor

- Case Palletizing Station

- FANUC M70iC, R1000iC or R2000iC series robots

- Features & Specs

-

The Robotic Pick-Pak-Pal includes:

- 6 axis FANUC robot selected for the application- FANUC M710iC robot

- The high speed and compact FANUC R1000 or larger R2000 robot can also be used in jobs where higher weight and/or longer reach are required.

- Fixed robot base anchored to the floor

- Custom, flexible end of arm tool for dual purpose case packing and palletizing

- Integrated FANUC iRVision system/2D Tracking software (optional per application)

- System wiring and controls

- Operator pendant or optional HMI display for recipe management

- Perimeter guarding with safety interlocks on doors

- Programming for Robot, PLC/PMC, HMI and Vision

- On-site Training and Support

- Compliance with all applicable RIA specified safety standards

- Mechanical and Electrical Engineering including layout of cell system, design, and detail