Build a Leaner, More Flexible, Highly Adaptable Workplace with Better Automation

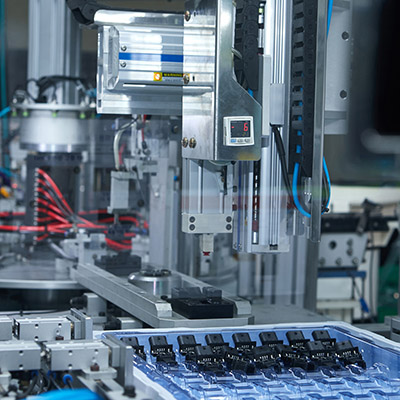

Reduce your need for costly human labor, eliminate safety risks to your workforce, and improve the throughput, scalability, and accuracy of your operations with automated systems to load and unload your presses, machinery, and products.

Improved Efficiency and Productivity

Robotic machine tending, press tending, and part load/unload systems can run through a night shift or over the weekend without human supervision, unlocking superior productivity and efficiency gains.

Safer Workplaces for Your Employees

Loading and unloading CNC machines present huge safety risks for your employees. Our automated press tending and machine tending systems eliminate the risks of repetitive motion injuries or burns.

Higher Quality Products

With robotic systems handling your machine, press, and parts loading and unloading, you reduce risks of handling damage, improve product consistency, and ensure more satisfied customers.

Your Automated Future Is

in Good Hands with Motion Controls Robotics

When you need a robotic machine tending system, MCRI is here to deliver. Since 1995, we’ve stood on the cutting edge of industrial automation, tackling the biggest challenges from Fortune 500 manufacturers operating in the most demanding industrial environments. We commit to building turnkey solutions tailored to provide you with a more competitive industry posture for years—or even decades—to come.

FANUC Level 4,

Certified Servicing Integrator

Our machine tending and press tending solutions are centered around FANUC robots, the gold standard in industrial robotics. As certified servicing integrators, we customize each system to meet your space requirements and efficiently solve your problems.

Proven Excellence in

Industrial Automation

MCRI is an award-winning robot integrator, recognized across the industry for our firm commitment to the highest quality and most innovative robotic solutions, as well as personal attention to the unique needs of every single one of our customers.

Customer Service

You Can Rely On

Our customers know they can rely on our people as confidently as they rely on our systems. We build loading/unloading and tending systems to last, support them through their entire service life, and are available 24/7 to address any issues and minimize downtime.

We Build Custom Part Load/Unload Systems That Can Handle…

Our robotic machine tending systems are built to handle all major brands and models of hydraulic and mechanical presses, CNC machines, and injection molding machines. We also work closely with you to customize off-the-shelf systems to automate loading and unloading for unique situations on your production floor.

Reap the Full Benefits of

Automation with Robotic Machine Tending and PressTending

-

Easily programmable, with:

-

Built-in operator pendants with stored recipes

-

On-the-fly process adjustments

-

User-friendly menu selection

-

-

Improved product consistency and accuracy

-

Unattended production enables night-shift and weekend running

-

Uptime of 80,000 to 100,000 hours minimizes downtime and maximizes productivity

-

Save on labor costs and worker compensation costs

-

Improve ergonomics for your workforce and minimize injury risks

-

Integration with vision systems for more consistent product inspection and minimal process variables

-

Precise, flexible servo-controlled systems along 6 axes of movement

-

Minimal footprint for space efficiency in small facilities

-

Quick changeovers using modular tooling and stored recipes

Building a Better Getting a Robotic Case Packer is Easy with MCRI

1

Design

Talk to us about what’s making loading and unloading difficult in your existing production floor setup. We’ll recommend the right robotic machine tending systems to solve your problems.

2

Build

Our team of engineers, programmers, and fabricators will work closely with you as they build robotic load-unload systems designed to fit your business needs and industrial environment like a glove.

3

Install and Support

Our work isn’t over after we’ve installed and certified your new load-unload systems. We continue to provide support, including onsite operator training, through your entire system lifespan.

We’re Here to Solve Your Biggest Machine Tending Challenges

The right robot can solve your biggest machine handling problems—and we’re all in on building it for you.

Robotic Machine Tending Resources

Tech Talk: LR Mate Robot Loading Unloading Kitako-Shimada

Kitako-Shimada machining cells are especially useful in the manufacturing of auto parts. In this case study, our customer needed a system to load and unload their machining cells as well as identify parts with a reliable vision system.

Tech Talk: Robot Places Well Tanks on Overhead Conveyor

Placing storage tanks onto a moving conveyor is risky business for human operators—so why not have a machine do it? Discover how we built a robotic machine tending system for safer, more efficient loading and unloading.

Tech Talk: Robots on Rails

By expanding your load/unload robots’ range of movement, a judicious application of rails can enable one robot to do the work of two, optimizing your process efficiency with less floorspace and fewer maintenance requirements.