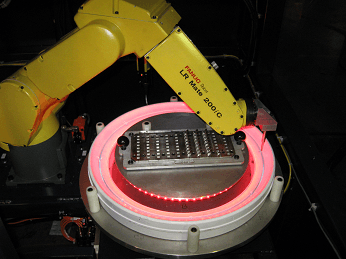

Robotic Assembly

Motion Controls Robotics can develop high speed robotic assembly cells using vision to locate all parts and subassemblies, descramble and determine a pick orientation for proper assembly. A high speed robotic assembly system provides a variety of benefits including reduced labor, ergonomic issues and scrap, as well as increased quality and throughput. A robotic assembly cell using vision is more flexible and cost effective than a fixed hard automation solution. The flexibility of a robotic system can accommodate process variation for hot or cold plastic parts. A six axis robot equipped with a force sensor can insert subassemblies and handle more difficult assemblies such as clutch plate assemblies.