In a recent episode of the Robot Industry Podcast, hosted by Jim Beretta, Scott Lang, the President and CEO of Motion Controls Robotics (MCRI), discussed robotics and automation from the perspective of what is happening today and then looking to the future. The conversation covered a broad spectrum of topics, including consumer buying habits, the significance of end-of-line solutions, and the future of the robotics industry.

Motion Controls Robotics: A Brief History

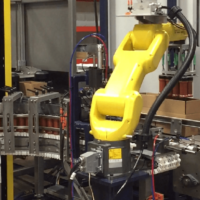

Motion Controls Robotics, established in 1995, positioned itself at the forefront of automation growth for non-automotive industries. Scott explained that the company initially focused on controls work for custom machine builders. By 1996, MCRI had ventured into robotics, becoming a FANUC Authorized Systems Integrator. Over the years, MCRI has honed its expertise in end-of-line and general material handling, distinguishing itself as a specialist rather than a jack of all trades.

Robot Industry – End-of-Line Solutions and Palletizing Innovations

A major part of their conversation revolved around end-of-line solutions, which MCRI specializes in. Scott explained that end-of-line encompasses everything from secondary packaging (after the product is initially wrapped) to creating unit loads ready for shipment. This includes case erecting, packing, sealing, labeling, conveying, palletizing, and stretch wrapping.

Scott also mentioned the trend towards modular and portable palletizing systems, which offer flexibility and ease of use. The advent of modular and portable palletizing systems has significantly reduced the upfront engineering required for automation cells, allowing for quicker deployment and greater flexibility. These systems can be assembled from pre-manufactured components, tailored to specific applications, and are often operational within weeks. Furthermore, advancements in software and user interfaces have made it easier for users to build and manage unit loads, enhancing efficiency and reducing the need for specialized engineering skills on the factory floor.

MCRI’s BA Palletizer, a portable unit that can be operational within 15 minutes and the Dual M-Stack Modular Palletizer, exemplify this trend. Such solutions are crucial in an industry facing a significant shortage of skilled labor.

Key Concerns of Manufacturers: Expertise & ROI

When asked about the primary concerns of manufacturers seeking automation solutions, Scott emphasized the importance of application expertise. Manufacturers prioritize working with experienced integrators with a proven track record to minimize risks and ensure the successful implementation of automation projects. This expertise is especially crucial in industries like food and beverage, consumer packaged goods, and general manufacturing, where MCRI has a significant presence.

The company’s focus on specific areas rather than a broad-spectrum approach has allowed it to develop deep expertise, thereby providing reliable and effective solutions to its clients.

ROI is also top of most facilities minds when developing an automation project. Scott explained why the ROI conversation has become more complex, “There is a fundamental lack of labor and that’s going to continue for the next decade or so. This changes the ROI conversation because it’s not that companies are eliminating positions, but you are never able to find those people in the first place.” That means you are not meeting delivery dates and expected throughput. The only way to actually do business is to add automation. Scott concluded that the ROI is averaging in the 2–3-year range.

A Changing Landscape in the Robot Industry: Consumer Buying Habits and Automation Needs

The conversation between Scott and Jim highlights the growing importance of automation in addressing the challenges faced by the warehousing industry.

The shift from in-store purchases to online orders has fundamentally altered the landscape of warehousing and retail operations. As consumers increasingly demand quick and efficient delivery services, facilities are compelled to adapt, leveraging automation to meet these new expectations. Scott highlighted how businesses are adapting by integrating full pallet loads of homogeneous products into Automatic Storage and Retrieval Systems (ASRS). This process involves depalletizing, storing, and then reassembling mixed pallets based on customer orders, showcasing the vital role of flexible automation solutions.

Another noteworthy development in the warehousing industry is the concept of induction, which refers to the process of integrating full pallet loads into an ASRS. This system allows for the efficient depalletizing of homogeneous products and the subsequent creation of mixed loads tailored to specific customer orders. This adaptability is crucial in an era where consumers expect a diverse range of products delivered directly to their homes or smaller retail outlets. By automating these processes, companies can meet consumer demands more effectively while optimizing their supply chain operations.

The Future of Robotics: AI and Digital Twin Technology

Looking ahead, Scott pointed to Artificial Intelligence (AI) and digital twin technology software being developed by Rockwell Automation are game changers in the robotics field. These technologies are expected to bring significant advancements, making automation systems more intelligent, error proof, flexible and efficient. Vision systems, which MCRI uses extensively for tasks like case location and depalletization, are also set to become more sophisticated with AI integration.

Robotic Industry Trends Conclusion

The Palletizing and End of Line Automation podcast provided a comprehensive look at the current state and future of robotics in manufacturing. Scott’s insights underscored the importance of expertise, innovation, and adaptability in meeting the evolving needs of manufacturers. As MCRI continues to develop cutting-edge solutions, the company remains at the forefront of transforming manufacturing processes through advanced robotics and automation technologies.

As the industry continues to evolve, companies like Motion Controls Robotics will play a pivotal role in driving the innovation that enables facilities to navigate the complexities of modern manufacturing, warehousing and distribution with confidence.

For more information on Motion Controls Robotics further explore our website or contact us at sales@mcri-us.com to ask questions about robotics. To listen to the full podcast episode, check out the Robot Industry Podcast hosted by Jim Beretta.

With a fundamental shortage of labor expected to persist, automation provides a viable solution for businesses to maintain productivity and meet customer expectations. The emphasis on uptime over cycle time underlines the need for reliable and predictable systems that ensure continuous operation.

Just as a landscape adapts to the changing seasons, facilities are evolving to meet new consumer demands.