Robotic Solutions for Medical Manufacturing

Manufacturers and suppliers across the healthcare industry supply chain have some of the highest and most stringent standards for end-of-line processes and quality control—demanding machines that can run reliably and continuously, reduce risks of human error and workplace hazards, meet high accuracy and quality standards, and ensure sterile handling of sensitive and critical medical products.

Deliver critical healthcare equipment easier than ever with flexible, accurate, reliable end-of-line medical robotics.

Tackle the Toughest Challenges in

Handling Medical Products

With highly efficient, easy-to-clean, easy-to-use FANUC robots, MCRI delivers highly customized, highly flexible medical robotic systems that make your processes more sanitary, more ergonomic, more efficient, and more adaptable while improving your throughput and strengthening your ability to compete in the medical device and equipment supply chain.

Flexible, Adaptable Operations

Cleaner, Ergonomic Environments

Consistent High Throughput

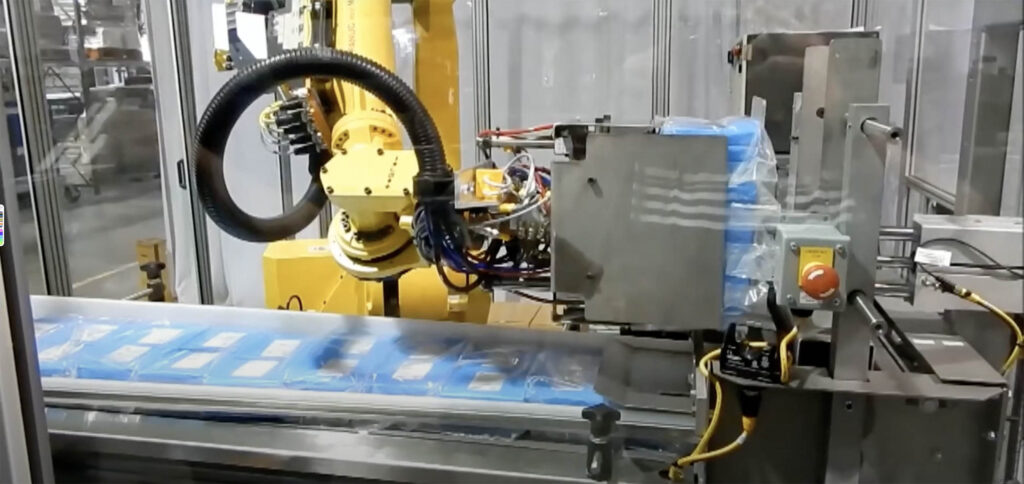

See Our Medical and Healthcare Processing and Packaging Robots in Action

Industrial Applications for

Medical Robotics

Robotic Labeling

Connect industry-leading FANUC robots to MCRI’s revolutionary database connectivity software for accurate, dynamic label printing and product tracing.

Case Packing

Start the packaging process with dynamic case erecting, sealing, and inspection robots built to handle medical products of any shape or size.

Picking and Sorting

Sort and pick products to build specific medical kits, trays, totes, or other containers, with easy load and unload features for convenient sanitizing.

Medical Robotic Palletizing

Handle various products and packages efficiently and improve your throughput with flexible palletizing solutions built to fit your facility like a surgical glove.

Clean Room Robots

Handle sterile products and equipment with highly efficient robots built to meet IP67 standards and withstand harsh and corrosive environments.

Get started bringing the perfect medical robotic systems into your process lines.

Achieving Medical Product Handling Efficiency with Motion Controls Robotics

Since 1995, Motion Controls Robotics has stood at the forefront of custom robotic systems for manufacturing and packaging lines across the medical and healthcare industry. Whatever your niche in the industry, our FANUC certified servicing integrator capabilities are at your disposal to streamline your picking, packing, and palletizing operations and deliver critical medical equipment to healthcare facilities and patients in need.

Drums

Blended Bags

Wipers/PPE

Precision Labeling and Documentation

Automated Assembly

Blister Packs

Tyvek sealed or WIP trays

IFU (Instructions for Use)

Reagent Bottles or Vessels

And More!

MCRI Makes Medical Robotics Integration Simple

1

Design

Where are your processes falling short? What issues are holding you back? Tell us and we’ll help you select the right robotic solutions for your facility’s problems.

2

Build

Our engineers, programmers, and fabricators have extensive experience building custom systems that meet the strict medical industry standards your processes must uphold.

3

Install and Support

Our comprehensive installation support, 100% QC checks, and operator training ensures your new medical robotic systems are integrated with minimal disruptions.

Whatever Automation Challenge You Face, We’re All-in on Overcoming It

Reach out to us today to find out what the best in medical robotic systems can do to sharpen your long-term competitive edge.

Medical Industry Robotics Resources

Tech Talk: High-Speed Labeling for Case Labeling

Discover the ways our robotic solutions can help medical industry manufacturers make significant efficiency and accuracy gains in applying custom labels to a wide variety of healthcare products.

Tech Talk: Case and Drum Palletizing with One Robot

Explore the solutions we provided to a customer in the healthcare industry who needed a single robotic work cell that could handle palletizing medical products of multiple sizes.

Tech Talk: Tray Handling Case Study

See what happens when a MCRI customer uses our custom tray handling robot systems to improve the efficiency, accuracy, and safety of their product handling operations.