Powerful Data Gathering Transforms How Real-time Production Information is Used by Decision Makers

Motion Controls Robotics to Launch their New Industrial Software Department to Help Customers Connect Production and Front Office.

Fremont, Ohio – Since 1995 Motion Controls Robotics, Inc (MCRI) has provided the highest quality robotic automation systems to a variety of industries. Building on this background knowledge, MCRI is shifting from exclusively integrating robot systems to providing complete end-of-line, fulfillment, and distribution solutions that include Industry 4.0 connectivity options. As a result of this shift, MCRI has developed an Industrial Software Department to focus solely on this area of software development.

Cameron Downs is the Head of Software Development for the Industrial Software Department. Cameron is a Computer Science major from the University of Toledo. Downs has spent his career configuring and designing software for distribution and fulfillment centers.

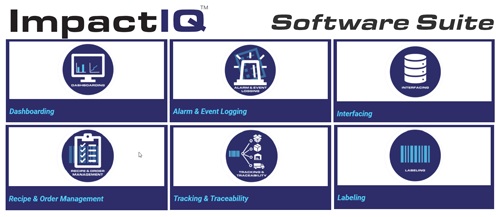

Downs will be leading the charge of advancing MCRI’s ImpactIQTM software platform to align with Industry 4.0 standards including production data visualization and analysis that highlights the efficiency of production lines and robot cells. In addition, this software will help identify process deficiencies, track energy usage, and identify maintenance issues before downtime events occur. Moreover, MCRI is putting this data in the hands of the people that need to know through mobile dashboards and tablets.

“I am getting data out of your machines and putting that data at your fingertips so it can work for you,” explains Cameron Downs, Head of Software Development.

This business expansion makes MCRI a unique integration choice based on:

- Over 26 years of experience integrating and servicing FANUC robot systems.

- Excellent safety record for our facility and in developing robot cells for customers’ needs.

- Database connectivity to connect the plant to the front office for quick and accurate data gathering.

- Proprietary Industry 4.0 software for tracking & traceability

Scott Lang, President of MCRI, concludes, “I see the convergence of front office software development and plant floor automation as a key component in the current phases of Industry 4.0.”

Cameron Downs is thrilled to be a part of the Motion Controls Robotics’ team and to further his career by working in a field he finds very integral to the future of manufacturing and industrial growth.

Motion Controls Robotics is excited to continue the journey into Industry 4.0. Contact MCRIContact Motion Controls Robotics to learn more about how this could improve overall plant efficiency – whether it is an add-on to a current system or the development of new system.

Motion Controls Robotics is excited to continue the journey into Industry 4.0. Contact MCRIContact Motion Controls Robotics to learn more about how this could improve overall plant efficiency – whether it is an add-on to a current system or the development of new system.

About MCRI

Motion Controls Robotics (MCRI) provides solutions for customers by designing and building turn-key end of line applications, fulfillment solutions, and general material handling automation. MCRI offers unmatched capabilities to elevate companies to the next tier of Industry 4.0 by combining automation expertise with full plant and front office connectivity interfacing with ERP/WMS systems.

MCRI has been implementing robotic automation since 1995, is a Certified Servicing Integrator for FANUC America, and Certified Integrator by the Robotics Industry Association.