Are there apprehensions about using Bluetooth devices in your automation system? Industrial Bluetooth solutions are much more robust than the current mobile device uses. Motion Controls Robotics had the opportunity to learn more about using Bluetooth devices when one of our customers had a large project where the best answer for everyone was to go wireless.

Below is a Q&A addressing many of the questions that arise when companies start to consider using Bluetooth in an industrial environment:

![]() Will it take a lot of extra training and time to install the Bluetooth devices?

Will it take a lot of extra training and time to install the Bluetooth devices?

![]() No, Phoenix Contacts helped us to develop a Bluetooth Wireless solution, and this saved about 100 hours of labor in wiring and soldering. The project required a robotic system to palletize cases of product onto 16 different pallet locations using a 50 foot rail system and five robots. The I/O needs of this system required large lengths of high-flex cable. This seemed like a poor solution since high-flex cables are not only time consuming to wire, but cause downtime because of breakage.

No, Phoenix Contacts helped us to develop a Bluetooth Wireless solution, and this saved about 100 hours of labor in wiring and soldering. The project required a robotic system to palletize cases of product onto 16 different pallet locations using a 50 foot rail system and five robots. The I/O needs of this system required large lengths of high-flex cable. This seemed like a poor solution since high-flex cables are not only time consuming to wire, but cause downtime because of breakage.

![]() Bluetooth devices that I have seen have a range of about 30 feet – wouldn’t this be limiting in an Industrial environment?

Bluetooth devices that I have seen have a range of about 30 feet – wouldn’t this be limiting in an Industrial environment?

![]() There is a class of Bluetooth that is specifically for industrial use. These devices have a range that can extend to 300 feet. This distance is possible because it operates in the 2.4 GHz license free spectrum. This was also perfect for our project since we had a 50 foot rail that the robots would slide along.

There is a class of Bluetooth that is specifically for industrial use. These devices have a range that can extend to 300 feet. This distance is possible because it operates in the 2.4 GHz license free spectrum. This was also perfect for our project since we had a 50 foot rail that the robots would slide along.

![]() Wouldn’t there be too much interference with the signal in such a noisy environment where Wi-Fi signals would also be transmitting?

Wouldn’t there be too much interference with the signal in such a noisy environment where Wi-Fi signals would also be transmitting?

![]() Most noises common in an industrial environment are on a lower frequency and therefore they do not interfere with the signal. Wi-Fi signals do operate in the same 2.4GHz spectrum, but Bluetooth technology includes Adaptive Frequency Hopping (AFH). AFH detects and avoids these wireless frequencies.

Most noises common in an industrial environment are on a lower frequency and therefore they do not interfere with the signal. Wi-Fi signals do operate in the same 2.4GHz spectrum, but Bluetooth technology includes Adaptive Frequency Hopping (AFH). AFH detects and avoids these wireless frequencies.

![]() Since this is newer technology, won’t the cost outweigh the benefits?

Since this is newer technology, won’t the cost outweigh the benefits?

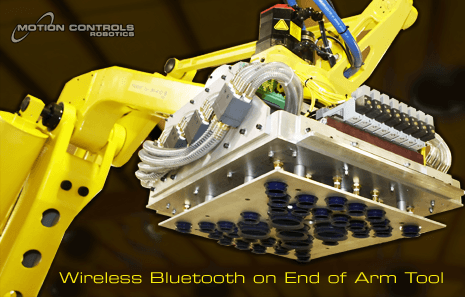

![]() Using Bluetooth is becoming very popular because of the flexibility and scalability of use and the low power consumption. The cost of these devices is fairly low and the maintenance requirements down the road, when compared to cable breakage, is a huge bonus. Time and cost was exactly what made us look at using a Bluetooth solution. Our end of arm tool only had 8 inputs and outputs and we needed 16 outputs. The expensive and vulnerable solution of running more high-flex cable just didn’t seem like the best answer for our customer. So the Phoenix Contacts’ Bluetooth wireless solution became the best way to get the extra outputs needed and keep cost down.

Using Bluetooth is becoming very popular because of the flexibility and scalability of use and the low power consumption. The cost of these devices is fairly low and the maintenance requirements down the road, when compared to cable breakage, is a huge bonus. Time and cost was exactly what made us look at using a Bluetooth solution. Our end of arm tool only had 8 inputs and outputs and we needed 16 outputs. The expensive and vulnerable solution of running more high-flex cable just didn’t seem like the best answer for our customer. So the Phoenix Contacts’ Bluetooth wireless solution became the best way to get the extra outputs needed and keep cost down.

If you would like to further explore using Bluetooth technology with your robot system, contact us for more information.