by Chris Shepherd, Motion Controls Robotics Inc

Successful operation of a robot is highly dependent on the robot’s end of arm tool design and the total payload, and whether or not the proper robot was selected for the application. Proper robot selection needs to be based on the inertias of the loads to be handled by the robot, along with the inertias of the robot’s End of Arm Tool design.

Inertia and Robot Payload

Calculation of these parameters allows the robot integrator’s design engineer to determine what robot is needed for an application. Inertia values can also be used by the designer to adjust end of arm tool configuration and load orientation in order to optimize robot model selection and ensure the robot’s load will fall within the manufacturer’s design specifications.

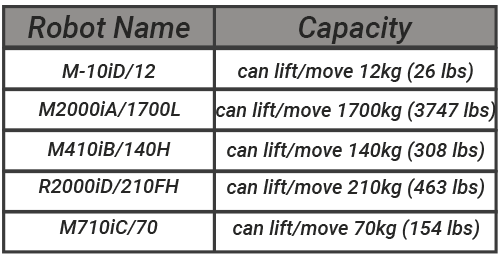

Identifying the payload lifting capacity of a FANUC robot is rather simple. It’s part of the model number. You can see in the chart on the right, the model number directly correlates to the payload in kilograms.

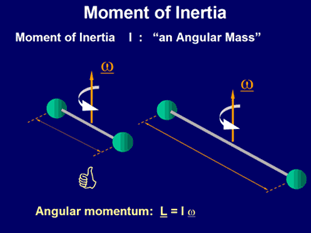

The Moment of Inertia

What is not as obvious is that each robot, specifically each joint of a robot, has a limit to how fast it can move different loads. The robot may be able to move a large mass, but it may not be able to move the mass quickly. In certain paths, the robot may not be able to move the mass at all. The determining property of the load is its moment of inertia.

What is not as obvious is that each robot, specifically each joint of a robot, has a limit to how fast it can move different loads. The robot may be able to move a large mass, but it may not be able to move the mass quickly. In certain paths, the robot may not be able to move the mass at all. The determining property of the load is its moment of inertia.

All payloads have the properties of weight and moments of inertia. Merriam-webster.com defines moment of inertia as:

a measure of the resistance of a body to angular acceleration about a given axis that is equal to the sum of the products of each element of mass in the body and the square of the element’s distance from the axis”

The moment of inertia depends on three things:

- the mass of the load

- the shape of the load

- how the load mass is distributed over the shape of the load.

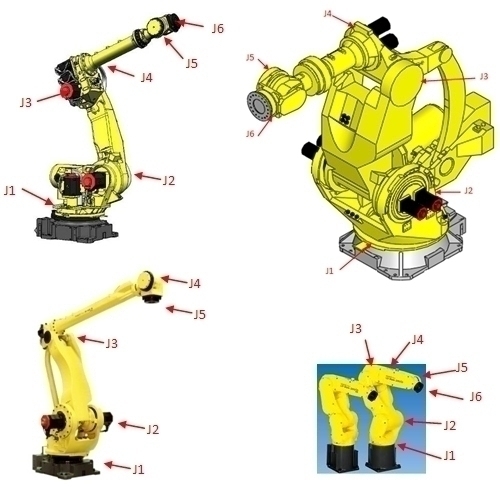

It is not dependent on gravity, so inertia calculations for a robot arm operating in outer space are just as important as they are here on earth! Depending on the robot model, a robot’s joints and servos are typically bigger/stronger near the base and smaller/weaker toward the faceplate where an EOAT (End of Arm Tool) is connected.

To determine if a robot will be able to perform a task, the capacity of each joint must be considered.

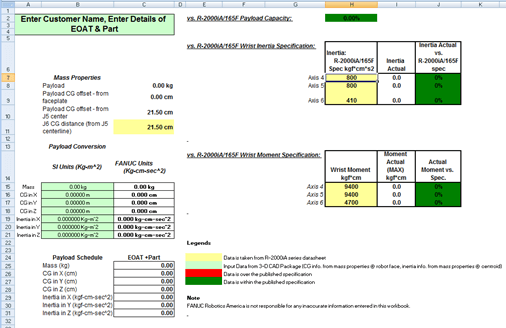

FANUC provides us with a software tool to check if the payload we have designed falls within the capacity of each robot and all the joints, but it is our responsibility to design the tool and to calculate the moment of inertia for all possible conditions. Motion Controls Robotics, Inc. has CAD software tools to accurately determine the moment of inertia for everything we design.

For further information about moments of inertia calculations, CLICK HERE for formulas for a variety of shapes.

The moment of inertia can typically be manipulated within reason. A designer can raise or lower the moment of inertia of a load simply by changing the shape of an End of Arm Tool, even without changing the mass of the load. Similarly, the moment of inertia can be changed without changing the shape but by changing the mass of the load. An example might be changing the tool material from steel to aluminum. Since the moment of inertia is dependent on the location of the rotational axis, it can also be manipulated by moving the load closer to, or farther from the rotational axis, or by changing the load position relative to the axis.

Designing an End of Arm Tool that will optimize the life of a robot is of the utmost importance to our customers. Selection of the proper robot to optimize cost while ensuring that the selected robot will perform properly over its expected life is even more important to our customers. Motion Controls Robotics, Inc. is a Level 4 Certified Servicing Integrator of FANUC robots. We have all the tools and experience to select the right robot and to design a robust End of Arm Tool that will last in your robot application for years.