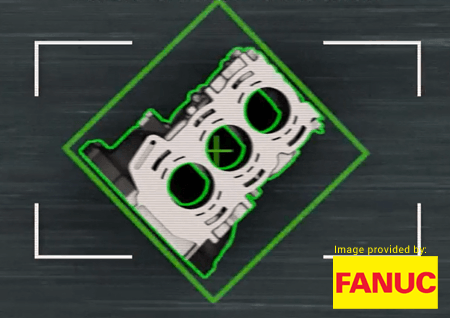

The world of digital cameras has been evolving and improving at a record pace. There are machine vision cameras specifically designed for almost any vision process need from high speed operations to detailed part inspection. Increasingly popular are cameras for code reading and special line cameras for cylindrical objects or color sorting. Camera housing options are also expanding and capable of protecting cameras in demanding environments.

Increasingly popular are cameras for code reading and special line cameras for cylindrical objects or color sorting. Camera housing options are also expanding and capable of protecting cameras in demanding environments.

This variety of options makes it possible to select the camera that best suits your needs with respect to field of view, resolution, speed, and cost. When selecting a camera, be sure to identify the spectral response of the camera to verify sensitivity to the light wavelength of your lighting choice.

Black and White Standard Resolution (640 x 480)

| Pros | Cons |

| Inexpensive | Low resolution |

| Faster image acquisition | Small Field of View |

| Easily inspect non-color sensitive parts

|

Black and White High Resolution (1360 x 1024 or higher)

| Pros | Cons |

| Large Field of View | More Expensive |

| High resolution for inspection processes | Slower image acquisition times |

Color Camera

| Pros | Cons |

| Can be used to distinguish color variations that may not be visible in the grayscale image | Most Expensive |

| Can locate parts that have a color difference but lack any distinguishable characteristics | More difficult to configure |

| 3 times more data than with grayscale images | Slowest image acquisition times |

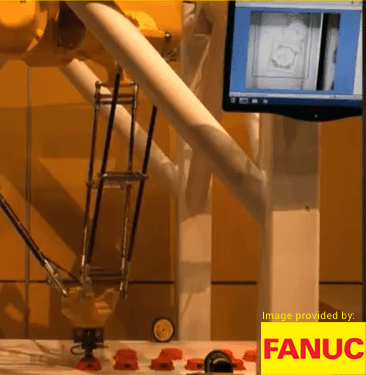

Motion Controls Robotics uses Fanuc or Cognex Cameras in our vision systems. Cognex supports a wide variety of cameras for almost any application. Over the next few weeks MCRI will continue to help you explore each category of Basic Machine Vision Hardware. Next week we will be discussing lenses. You will learn how selecting the proper lens for your camera can improve your vision application. If you would like to learn more about Basic Machine Vision Hardware,contact our sales group.