The building material industry is an area, similar to the automotive industry, that can greatly benefit from the integration of robots into their manufacturing and material handling process. Overall material handling operations using robots has increased by 11% in the last year as reported by Robotics Industries Association (RIA). The main drivers for this increase are a need for a safe work environment, cost reduction, consistent manufacturing results, and increased quality through minimizing product damage.

Motion Controls Robotics recently published a case study and video showing the benefits of automating board or panel handling in the building and construction industry. Automating this type of process has solved issues such as:

- Uneven stacking – leading to both safety and transportation issues

- Employee turnover and injuries – lifting and stacking heavy boards is both dangerous and can cause injuries over time

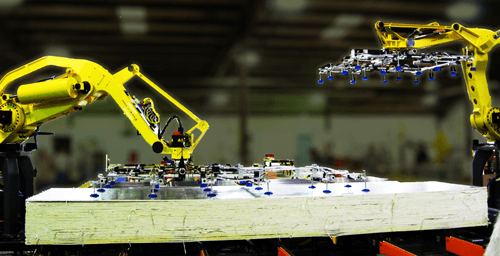

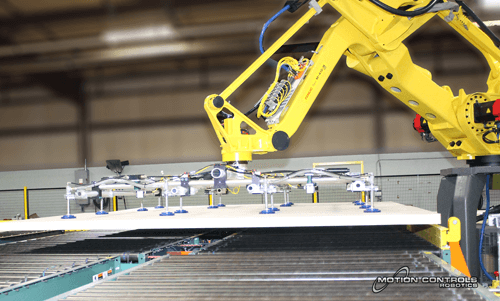

This video shows the panel stacking system Motion Controls Robotics developed using two FANUC M-410iC robots.

The board handling case study explains the problems the company first faced with manual panel stacking, the solution that Motion Controls Robotics used to solve these problems and the final results for the company. Today the company has implemented this system into several processes and has seen great results.

Read the case study to learn more about the project and contact Motion Controls Robotics through our online robotics request form to discover how automation can improve material handling operations in your facility.