The newly developed M-20iD series is a combination of the benefits of two different M-20 robots merged into one robot. These models both have positive attributes suited for certain applications, but in today’s industry, FANUC realized adding them together in one robot would greatly benefit customers. The resulting M-20iD is just an improved version that installs and operates just like the older versions.

Top Nine Benefits of the Robot Merge

- Taking the J1 base of the M-20iA gives the robot high strength and rigidity.

- The M-20iD has a slightly smaller profile while still improving payload and reach.

- The speed of each axis has been increased because of improved design and drive train.

- The stronger wrist adds to the now improved repeatability ( +\-.02mm)

- This robot can reach closer to its own base, improving the active stroke.

- Smoother surfaces minimize dirt build up and IP67 protection on arm and wrist axis makes this the model for dirtier environments.

- A hollow wrist allows for cable routing through the wrist. This keeps the cables from extra wear and damage.

- Specially designed to minimize interference, the M-20iD/25 is ideal for crowded production environments.

- Installation options are improved and running costs are low.

By combining performance with reliability, the FANUC M-20iD/25 maximizes throughput leading to higher profitability.

2⃣ #Robots – Including the new #FANUC M-20iD/25 – Pick & pack jars of candy from conveyors in a 2×3 pattern. This repetitive job is great for our highly reliable & accurate #robots. Learn more at https://t.co/9Wp0oJlj28 #packexpo pic.twitter.com/9skHiTWOod

— FANUC America (@FANUCAmerica) September 25, 2019

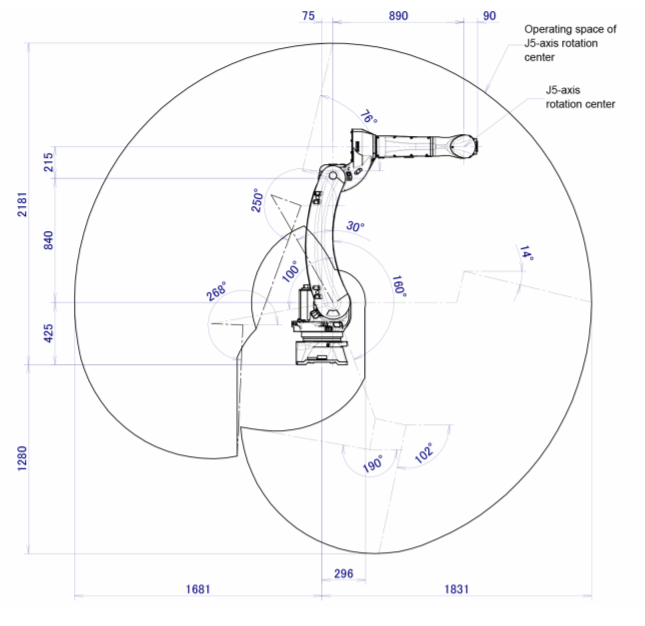

M-20iD Robot Specs

Model |

Payload |

Reach |

Download Spec Sheet |

| Floor, Upside-down, Angle Mounted – Hollow Wrist | |||

| M20iD/25 | 25 kg | 1853 mm | M-20iD-25.pdf |

See other M20 Models that are available >>

Applications for the M-20iD

Machine load and unload

The smaller footprint and larger reach of the FANUC M-20iD/25 is ideal for loading and unloading machines and other part handling applications.

Assembly

The improved repeatability makes the M20iD a perfect contender for assembly applications.

Case Packing

Picking items and placing them in a case in a small footprint cell would be just the start. The M-20iD can move flexibly around the cell and add assembly, labeling, and/or kitting of products before placing in a case.

Integration Examples that included a M-20 model robot.

Controller & Options

There are two controller options available for the M-20iD.

- R-30iB Plus controller – the statandard controller for medium to large robots

- R-30iB Mate Plus controller – a smaller footprint controller used with small robots

The robot & controller offer:

- integrated vision system

- larger memory

- faster CPU

- iPendant

- Ethernet

- ASi

If you want to see how this new model can improve your current application, Motion Controls Robotics can develop a simulation using ROBOGUIDE which already contains the robot specs.