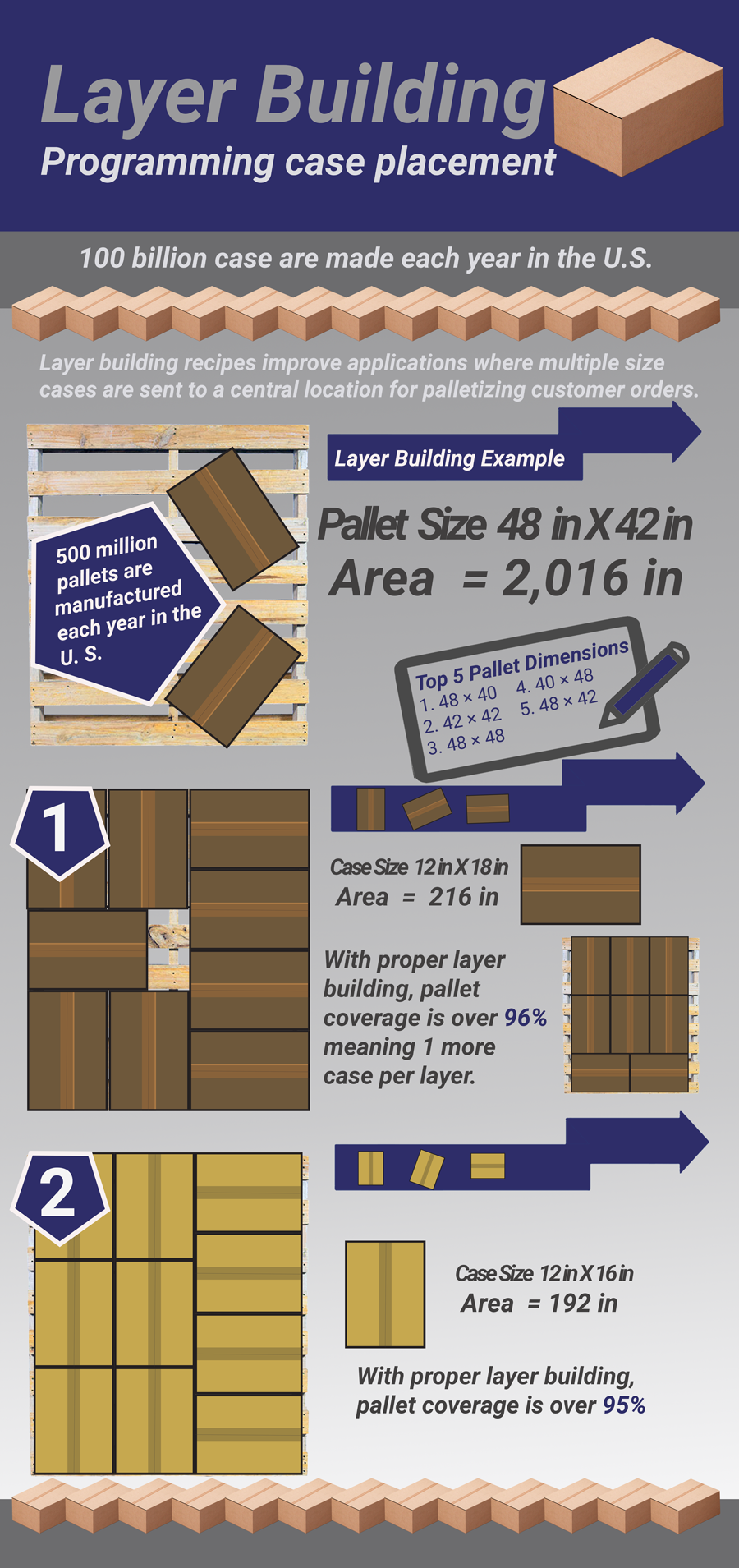

Layer Building for Palletizing

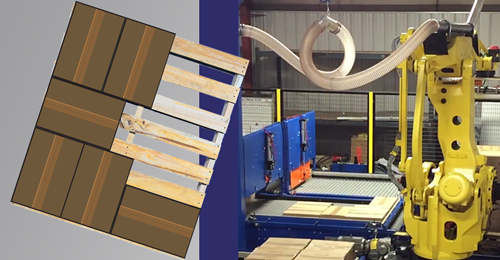

Layer building is sorting, organizing, and maximizing the space available on a pallet to efficiently place the cases. In this article we are going to discuss layer building on a conveyor build station where full layers are then picked by a vacuum end of arm tooling and a palletizing robot.

Benefit of Palletizing Layer Building

- Layer building at a build station saves time over pick and place stacking on pallets.

- The option to have operators select built recipes or build new recipes directly from the HMI improves efficiency of processes that have a lot of product variety running.

- Layer building improves applications where multiple size cases are sent to a central location for palletizing your customer orders.

- A single robot can palletize up to 4 lines simultaneously.

- High volume case production can be palletized with less robots.

What is a recipe?

Alton Brown taught us all the importance of a recipe and the chemistry involved in cooking. If all the ingredients don’t work well together at the proper percentages, then you get a pretty poor result. The same is true of programming. The right information must be input into the recipe for the application to work correctly.

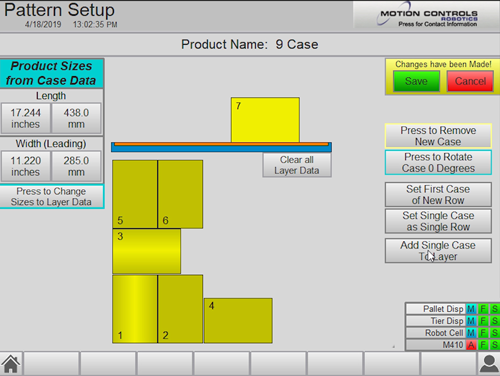

A programming recipe for layer building is a solution for how to build a layer based on the size of the case and pallet. The recipes are setup and saved to the system. Then the operator selects the correct recipe for what is running on the line and a beautiful stack of cases will be the result.

How to Build Palletizing Layers

Cases which are most commonly squares and rectangles are shapes that tessellate. Squares don’t take a lot of managing but rectangles are a little trickier.

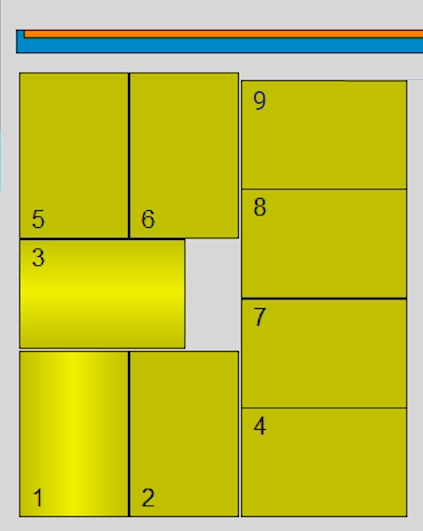

Let’s take a deep dive into an example of layer building. Figure 1 shows the final layer build we will discuss below and is same pattern featured in the video.

What you know

- The size of the pallet and the allowed stack dimensions

- The dimensions of each case

- You want to maximize the stack and keep the stack stable

- The cases enter the system in 2 orientations, wide or narrow edge leading.

- Cases are metered onto the conveyors with various gaping to allow for proper positioning of the case.

- Both conveyor speeds and bump turners are utilized to feed cases to the layer conveyor in the correct orientation.

Palletizing Layer Building Case by Case

(hint: watch video below first for better clarity of the steps)

- All cases types are fed into the conveyors in the same narrow edge leading orientation.

- The first case hits the lowered stop and the case begins to run sideways on end stop. The second case joins. The gap between cases on infeed conveyor allows the first case to clear before the second case arrives at end stop.

- Next, the third case hits the bump turn and enters the stack to the right side and slides into its spot in the layer.

- The fourth case gets a bump turn, the stop lowers letting the turned case run sideways along it, then the stop raises so case can move into the layer.

- The stop lowers again for the next two cases to slide along, raises to let them move into place finishing the left side.

- The last three boxes are bump turned and move directly into their spots finishing out the layer.

- While the robot is picking the layer, the first row of the next layer can be built.

Palletizing layer building is a great add on to your palletizing application. If you have interest in learning more about using robotics for your palletizing application, get in contact with MCRI. We can design a system and offer special time savers like layer building.

Layer Building Infographic

Area below should be listed as square inches.