Most robots fall into the categories of having one or more of the aspects of articulated, mobile, or collaborative robots. Motion Controls Robotics specializes in integrating Yellow mechanical robots, SCARA Robots, Delta Robots, Collaborative Robots, and AMRs into manufacturing, distribution, and logistics facilities. While an integrator can help you select the best robot type for your application, here are some of the characteristics of each robot to help you get a head start on which robot is best for your application.

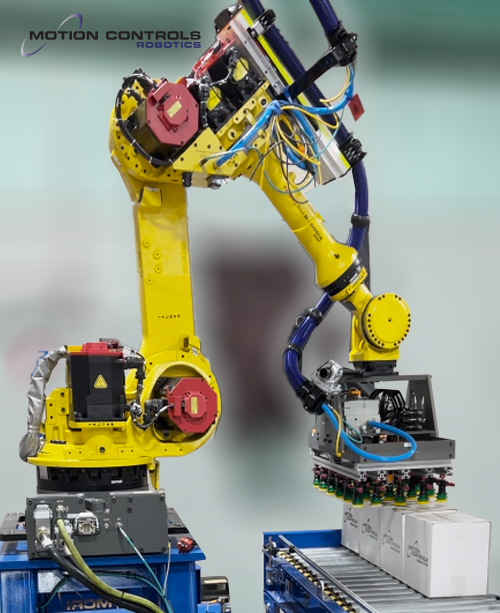

Mechanical Yellow Robots

Yellow, FANUC robots have been around since 1974. FANUC offers a variety of models of robots that not only meet the needs of certain applications, but some models are even specific to your industry. While Yellow robots have been sold at the largest numbers to automotive manufacturing companies, the tides are turning as other industries are seeing the immense benefit of automating with robotics.

The proper Yellow robot model is selected based on your throughput and payload needs. You can see the full list of robots here.

Yellow robots offer a variety of installation options:

- Wall

- Rail

- Overhead

- Floor

Robot installations tend to be fairly stationary because of the robot and part’s weight and for basic safety reasons. There are times when a rail can be added for limited movement usually along one axis.

Yellow robots are the best robot type for:

Reliability – FANUC robots offer the best reliability of any industrial robot with 8 years of maintenance free work.

Options – FANUC is bound to have the perfect robot for your application – no matter the payload or speed. Robots with higher payloads keep being introduced with the latest reaching almost 2.5. tons.

Efficiency – Adding robotics to a process increases throughput and decreases downtime. The consistency of production allows for more predictable scheduling.

Quality – Final product quality is improved through consistent movement and programmed tolerances.

Every manufacturing, distribution or logistic facility could install a Yellow robot for improved processes and better efficiency in some area of their facilty.

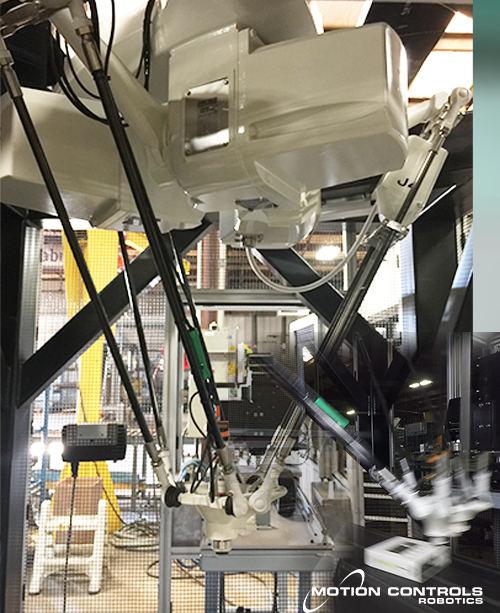

DELTA Robots

Delta robots are a newer option for facilities. Deltas started showing up in the early 1980s. They were first developed to pick and place chocolates at a very high speed. They are named after their triangular structure which resembles the Greek letter delta.

Today, Delta robots are found in a variety of manufacturing, distribution, and logistics industries performing task such as:

- Labeling – In combination with vision, Delta robots can quickly place labels in the exact same location on randomly oriented products on a conveyor – See an example of this application.

- Assembly – Deltas can perform precise assembly processes for electronics and other technology or medical industries.

- Pick & Place – Delta robots are typically used for pick-and-place applications, where they can quickly and accurately move lightweight objects.

Delta robots are parallel robots and high-speed masters. The key design feature is the use of parallelograms in the arms, which maintains the orientation of the end of arm tooling. These robots feature 3, 4 or 6 axis of movement and can place upwards of 100 parts per minute. Using delta robots for repetitive motion processes in your facility reduces injuries and allows employees to focus on something of more value – like quality control.

Delta robots are known for their speed, accuracy and flexibility. They are a cost-effective and efficient way to automate tasks. Deltas are becoming increasingly popular in a variety of industries because of their unique and high-speed qualities:

- Electronics

- Food and Beverage

- Healthcare

- Consumer Products

- Distribution

- Warehousing

- Packaging

Delta robots are the best robot type for:

Speed – Delta robots can reach high speeds and accelerations making them ideal for applications where time is of the essence.

Accuracy – Delta robots can position objects with a high degree of accuracy up to a fraction of a millimeter.

Flexibility – Delta robots can handle a wide variety of light-weight objects making them versatile and adaptable.

Cost-effectiveness – Delta robots are a cost-effective way to automate tasks.

In conclusion, Delta robots might be the right selection for you if you have a light-weight product that needs picked and/or placed at high rates.

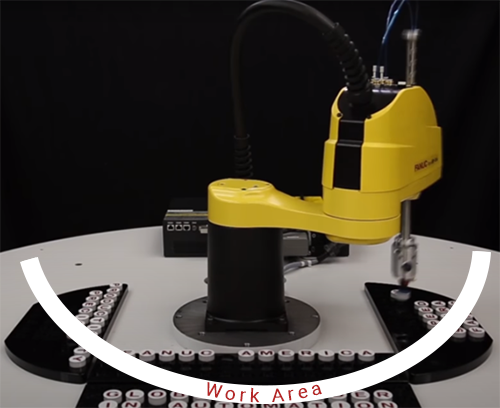

SCARA Robots

The first SCARA robot came about in 1978 – it wasn’t the exact same as it is today which is part of the reason for the acronym change from

SCARA- Selective Compliance Assembly Robot Arm >>>> SCARA – Selective Compliance Articulated Robot Arm

The question once you see the acronym might be, “what does compliance mean?” Compliance, in this instance, is what helps the SCARA robot get its accuracy and speed rating and makes it perfect for assembly. Compliance is a bit of a give or pushback in the robot arm to make up for small difference in parts. Without compliance, a  bolt in a specified tolerance might not fit exactly in the programmed location but my allowing for the tolerance movement of the robot arm the bolt will be inserted.

bolt in a specified tolerance might not fit exactly in the programmed location but my allowing for the tolerance movement of the robot arm the bolt will be inserted.

SCARA robots are known for their speed and accuracy in applications such as:

- Assembly

- Sorting

- Pick and Place

There are not as many models available as the other Yellow robots, but they have their need and place in the manufacturing & fulfillment environment. SCARA robots are 4 axis where they move upon a rod. They have a large work area, as seen in the image on the right, where the only place the SCARA can’t work is directly behind the installed area. If you discover that a SCARA robot fits your application needs, you are in luck, because they are also an extremely affordable robot solution.

SCARA robots are the best robot type for:

Speed – SCARA robots offer high speed work with the option of higher payloads of up to 44 pounds available.

Accuracy – SCARA robots can accomplish repeatability up to ± 0.01mm.

Flexibility – With some design and imagination SCARAs can be used for a variety of applications from simple sorting to more complex palletizing. This video from FANUC America shows the wide range of uses for SCARA robots.

Delta and SCARA robots both have a lot to offer manufacturing and distribution facilities and are used for many of the same types of application. One of the main differentiators is the payload. SCARA robots can offer a much larger payload than Delta robots.

Collaborative Robots

Collaborative robots are a newer concept with iterations beginning in 1996. These cobots, allow your employees to safely work alongside a robot or for the robot to be more portable by having some safety features inside the robot instead of outside, like safety fencing.

The collaborative robot moves at different speeds based on the defined environment and safety areas.

Cobots are becoming increasingly popular in a variety of industries for applications such as:

- Assembly

- Packaging

- Palletizing

- Labeling

Collaborative Robots are the best robot type for:

Productivity – The ease in setup means cobots are a great way to fill gaps in production areas. Cobots can also share floorspace and allow for more work to be done in the same area.

Safety – Cobots are designed to be safe for humans to work alongside. They have built-in force sensors and use area scanners to detect human presence and slow and stop the robot.

Flexibility – Cobots are easy to program and re-program, making them well-suited for facilities that need to change their production lines frequently.

Affordability – Cobots are less expensive to integrate than traditional industrial robots. This makes them a more affordable option for small and medium-sized facilities.

If you are looking for a safe, flexible and affordable way to automate tasks in your workplace, then cobots are a great option to consider.

Autonomous Mobile Robots

The autonomous mobile robot (AMR) is the oldest robot we are discussing with versions starting to be seen in the mid 1940s. With new technologies, today’s AMRs have really hit their stride in the manufacturing, warehousing, and logistics world to:

- Transport materials

- Pick up and deliver orders

- Deliver goods to or from people\processes

- Perform inspections and maintenance

An AMR is a robot that can navigate and move through its environment. AMRs are typically equipped with sensors, such as cameras and lidar, that allow them to perceive their surroundings. The AMRs use this information to avoid obstacles.

AMRs are being integrated because many companies have been able to improve productivity, efficiency, and safety by using these robots to transport goods. These mobile robots can be controlled and monitored remotely, which allows operators to track their location and status in real-time.

AMRs are the best robot type for:

Productivity – Moving products and materials around the facility is a repetitive and boring task, and AMRs can be used to free employees to focus on more important tasks, such as quality control and customer service.

Efficiency – AMRs have a schedule and stick to it so they can reduce bottlenecks and get products and materials to the correct location when it is needed.

Safety – AMRs navigate their environment and slow or stop for obstacles. This type of movement brings a safer environment than people having to navigate vehicles like forklifts. AMRs can be integrated with other systems and equipment, such as conveyor belts and automated storage and retrieval systems, to create a seamless and highly efficient workflow.

Overall, autonomous mobile robots represent a growing trend in industrial automation. As you look for ways to improve efficiency, safety, and productivity in your operations think about how AMRs can help. By leveraging the latest in robotics and automation technology, AMRs are poised to play an increasingly important role in a wide range of industries and applications.

If you would like to get started on your next robot/automation project, contact Motion Controls Robotics to find out more about the best robot type for your project.