High Speed Robotic Case Packing Operations

The robotic case packing system is flexible, precise, programmable and portable

A key advantage to robotic case packing for portion cup line applications is the ease and speed of changing to different sized cases and case layouts. Motion Controls Robotics has designed systems where there are at least nine different case sizes and layer orientation combinations. New case configurations can be quickly and inexpensively added in the future.

Simulation showing double layer end of arm tool

To meet even higher rates, we offer a double layer end of arm tool option.

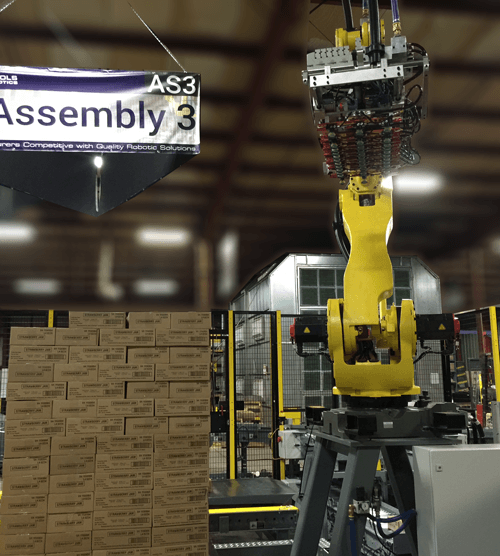

End of Line Palletizing for Full Cases

With our years of experience, we can increase your throughput while reducing costs

Robotic case palletizing systems that decrease costs with reductions in labor, ergonomic injuries and floor space. Proven custom case handling end of arm tools allow fast cycle times as well as quick changeovers.

Robotics for Food and Beverage

7 Ways We Help Relieve Your Stresses about Robot Integration

- MCRI has worked with a variety of food companies each posing complicated processes and hundreds of SKUs.

- MCRI can provide training for your internal operators to make sure everyone is ready to run your system.

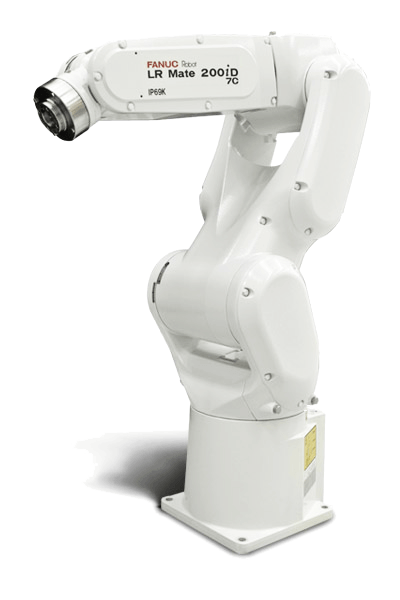

- FANUC food grade robot systems meet FDA safety standards.

- Robot systems offer a high degree of flexibility for changing packaging shapes, sizes and rates.

- Our robot system calculator helps you gauge the cost of your system.

- We use Dual Check Safety, machine vision innovations, and efficient layout design to decrease square footage needed for the overall robot system.

- Our 22 years of experience means we have designed and built fully automated applications from processing to palletizing.