DCS Part two (read part one) – How Could This Lead To A Fenceless Robot System?

The software tools outlined in part one, Dual Check Safety (DCS) Explained, can be used together to design safe, fenceless zones when installing robot workstations. The designer creates virtual checkpoints to establish monitored zones using area scanners, safety mats, and other safety sensors and, if required due to complexity and number of inputs, a safety PLC.

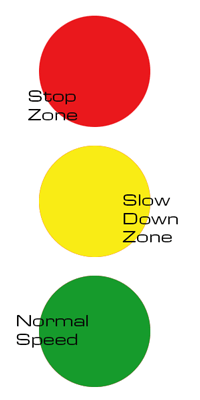

Through the use of these monitored zones, the speed and position of the robot is constantly controlled. Inside the fenceless robot system, the robot(s) works at a normal speed when safety zones have not been breached. If parts or supplies need to be loaded\unloaded within the cell, the operator may request access to the cell. Then the operator may enter an area of the cell without causing the robot to stop. The controller may command the robot to slow down, and/or restrict its motion so the operator can work safely while the robot continues to perform at least a portion of the robot cell’s normal duty cycle. If the operator continues to approach the robot, he enters a “stop zone” and brings the robot to an immediate stop.

Eliminating the safety fencing around the cell can reduce material cost, simplify and speed up operator access to the cell, and provide enhance visual factory, This is perfect for maintenance needs, quick part changeover, quality monitoring, and many other functions that operators and maintenance people may need to do within the robot cell.

Conclusion

DCS software creates a virtual fence around the work area. This programmable virtual space has safety characteristics that meet all RIA specifications including dual channel control.

DCS can be used to reduce the floor space required by a traditional, fenced in robot cell, or can simplify design of a fenceless robot cell.

A fenceless robot cell offers the potential to;

- simplify access to the cell for operator and maintenance interaction

- improve robot uptime and utilization

- improve lines of sight within the plant environment

With the software tools available in DCS, the system designer and programmer have the ability to increase productivity of a robotic work cell and reduce its cost while maintaining safety that meets RIA safety standards.

Contact Motion Controls Robotics through our robotic request for information form or at 419.334.5886 to learn more about how FANUC Dual Check Safety can improve your robot work cell.