The FANUC R2000iB series six- axis robot is versatile in the industrial environment because it has a compact form and slim arm. It is FANUC’s most popular robot. Despite its slim arm the R2000 robot actually has an industry leading payload capacity. There are nine models in the R200iB series, so there is likely one available to fit your application needs perfectly.

The R2000iB, as a result of its simplified, vertical articulated arm, has fewer mechanical components. This allows for less maintenance needs and an exemplary mean time between failure rate of 80,000 to 100,000 hours when applied correctly.

Suggested uses for the FANUC R2000iB include:

| Automotive spot welding and general assembly | Palletizing |

| General industrial applications | Part transfer |

| Material removal | Machine loading |

Motion Controls Robotics commonly uses the R2000iB robot for roll handling, machine load/unload and general material handling applications.

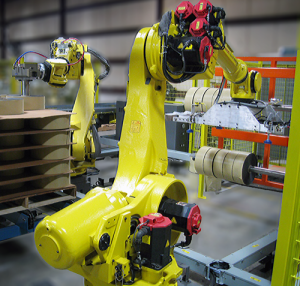

FANUC R2000iB – Robotic Teamwork

These two R2000 series robots are working together to pick and place rolls placed on a mandrel.

The robot on the right places the pallet and tier sheets. It then moves each roll onto the end of arm mandrel of the robot on the left. This R2000 robot on the left then either palletizes the roll or places it on a conveyor based on customer packaging requirements.

Watch Video

FANUC R2000iB – Roll Handling

In this roll converting robotic work cell, the R2000 is working with an M2000 series robot to turn jumbo rolls into slit, palletized rolls. The M2000 is FANUC’s largest payload robot. The M2000 moves a parent roll of slit product over to a mandrel. Then the small but strong R2000 grips the core of the slit roll and rotates the center axis of the slit rolls from horizontal to vertical orientation using an expandable ID gripper. The robot has the option to place a slip sheet between each roll.

The R2000 moves along a Gudel rail so it can select from a variety of pallets to place the roll. When a full pallet is removed, the R2000 quickly replaces the pallet and places a tier sheet to continue palletizing.

Bin Picking

The newest series of R200iB robots has intelligent functions improving the capabilities for bin picking through integrated vision, an area where MCRI is rapidly gaining experience.

Use our robotic request information form if you have questions about automation.