Robotic Order Fulfillment Solutions for Beverage Distribution

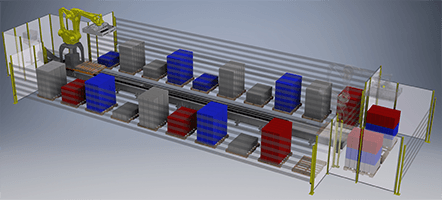

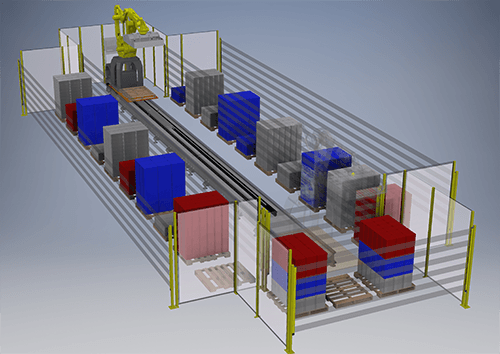

MCRI has developed a standard full layer mixed SKU palletizing system.

Below you will find basic information about the system and a downloadable tech sheet is available for system specifications.

Full Layer Mixed SKU

Palletizing System

The simulation video to the right shows mixed SKU, full layer pallets being built. The robot is picking a variety of 12 & 24 packs of 12 ounce cans from source pallets to build the order pallets. The robot and pallet travel up and down a Gudel Rail selecting the correct SKUs needed to build the mixed load pallet.

What to Expect from a Robotic Order Fulfillment Solutions for Beverage Distribution

Your full layer, mixed SKU per pallet, robotic order filling system will take advantage of:

- FANUC Robotics’ flexibility, performance, and reliability

- Custom end of arm tooling for improved flexibility and complexity of process

- Options for level of automation you require

- Use of multiple robots and Automatic Guided Carts (AGCs) if applicable

- Process and rate verification using simulation software (ie. PalletPro (TM) and Roboguide (TM))

- Order tracking and sorting with vision and scanning technologies

- Ongoing support through 24/7 Motion Controls Robotics Inc technical support and FANUC’s Service First and 24/7 service.

Motion Controls Robotics can design a mixed pallet, full layer order fulfillment system to meet your setup and needs. Each system will utilize the benefits of innovations and technologies that have repeatedly proven to increase efficiency and ROI.

Product Video

Robotic Order Fulfillment

A Robotic Beverage Distribution System Delivers:

- Improved accuracy in product selection

- Fewer customer returns and refunds due to picking errors

- Flexibility to change orders on the fly

- Better shipped load integrity and happier customers

- Centralized data entry and integration with ERP system

- Less damage in packaging – better quality retail-ready pallets

- Improved customer order fulfillment accuracy and satisfaction

- Improved bottom line of your distribution facility